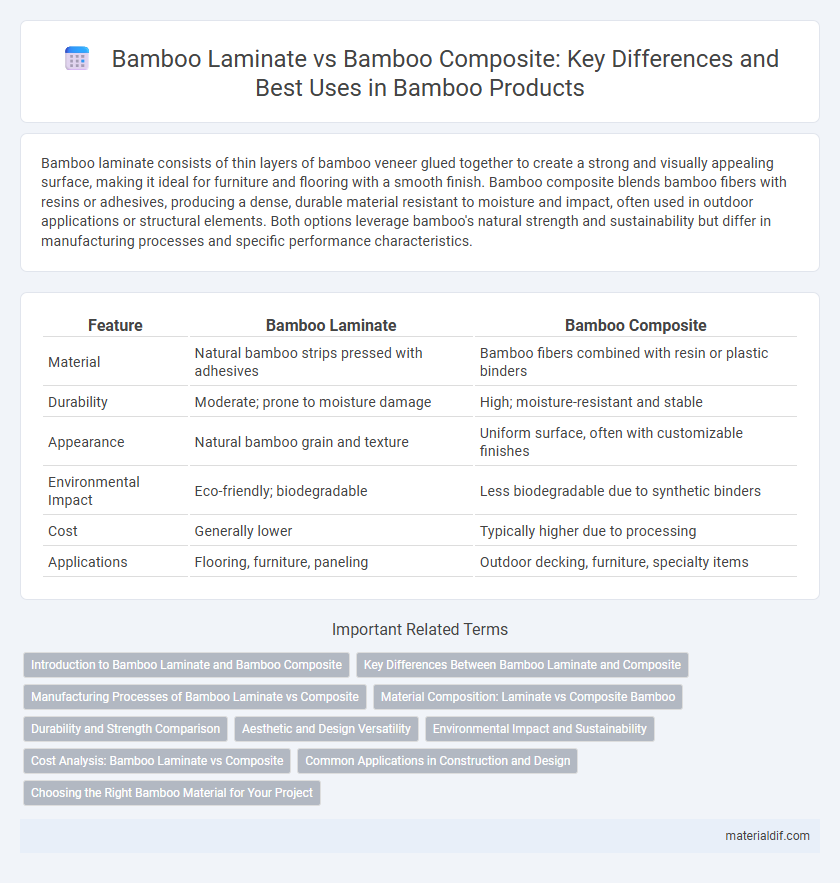

Bamboo laminate consists of thin layers of bamboo veneer glued together to create a strong and visually appealing surface, making it ideal for furniture and flooring with a smooth finish. Bamboo composite blends bamboo fibers with resins or adhesives, producing a dense, durable material resistant to moisture and impact, often used in outdoor applications or structural elements. Both options leverage bamboo's natural strength and sustainability but differ in manufacturing processes and specific performance characteristics.

Table of Comparison

| Feature | Bamboo Laminate | Bamboo Composite |

|---|---|---|

| Material | Natural bamboo strips pressed with adhesives | Bamboo fibers combined with resin or plastic binders |

| Durability | Moderate; prone to moisture damage | High; moisture-resistant and stable |

| Appearance | Natural bamboo grain and texture | Uniform surface, often with customizable finishes |

| Environmental Impact | Eco-friendly; biodegradable | Less biodegradable due to synthetic binders |

| Cost | Generally lower | Typically higher due to processing |

| Applications | Flooring, furniture, paneling | Outdoor decking, furniture, specialty items |

Introduction to Bamboo Laminate and Bamboo Composite

Bamboo laminate consists of thin layers of bamboo veneers bonded together under high pressure, creating a durable, visually appealing surface ideal for flooring and furniture. Bamboo composite combines bamboo fibers with resin or other binding agents, resulting in a strong, moisture-resistant material commonly used for decking and outdoor applications. Both materials leverage bamboo's rapid growth and sustainability but differ in structure and performance characteristics suited to specific uses.

Key Differences Between Bamboo Laminate and Composite

Bamboo laminate consists of thin layers of bamboo veneer bonded together with adhesive, offering a smooth, durable surface ideal for flooring and furniture. Bamboo composite combines bamboo fibers or particles with resins or other materials, resulting in enhanced structural strength and resistance to moisture, making it suitable for outdoor applications. The key differences lie in their manufacturing process, durability, moisture resistance, and typical uses--laminate excels in aesthetics and indoor use, while composite provides greater robustness and weather resistance.

Manufacturing Processes of Bamboo Laminate vs Composite

Bamboo laminate is produced by slicing bamboo strips, which are then glued and compressed under high pressure to create thin, durable sheets, emphasizing natural grain and aesthetics. Bamboo composite involves combining bamboo fibers or particles with adhesives and resins, which are molded and cured to form a robust material with enhanced structural properties. The manufacturing of bamboo laminate focuses on preserving bamboo's natural layers, while composites prioritize blending materials for increased strength and versatility.

Material Composition: Laminate vs Composite Bamboo

Bamboo laminate consists of thin layers of bamboo veneer fused together with adhesives, creating a durable yet flexible sheet ideal for flooring and furniture surfaces. Bamboo composite combines bamboo fibers with resins and other materials, resulting in a denser, more robust product with enhanced strength and moisture resistance. The key difference lies in laminate's layered veneer structure versus composite's homogenized blend, affecting durability, appearance, and application.

Durability and Strength Comparison

Bamboo laminate features multiple layers of bamboo veneer fused with adhesive, offering enhanced tensile strength and consistent durability suitable for high-traffic flooring and furniture. Bamboo composite integrates natural fibers with synthetic resins, providing superior resistance to moisture, warping, and impact, making it ideal for outdoor applications and heavy-use environments. Both materials demonstrate remarkable strength, but bamboo composite generally outperforms laminate in terms of long-term wear and environmental resilience.

Aesthetic and Design Versatility

Bamboo laminate offers a sleek, uniform appearance with consistent color and grain patterns, making it ideal for modern interior designs requiring a polished finish. Bamboo composite combines natural bamboo fibers with resins, allowing for customizable textures and enhanced durability that suit a variety of architectural styles. The design versatility of bamboo composite often surpasses laminate, providing greater flexibility in shaping and surface treatments for creative applications.

Environmental Impact and Sustainability

Bamboo laminate is made by pressing thin layers of bamboo strips with adhesives, resulting in a durable material but often involves synthetic resins that may emit volatile organic compounds (VOCs). Bamboo composite combines bamboo fibers with eco-friendly binders, offering enhanced biodegradability and lower environmental footprint by using fewer chemicals and promoting recycling. Both materials capitalize on bamboo's rapid growth and carbon sequestration, but bamboo composite tends to align more closely with sustainability goals due to its reduced reliance on harmful adhesives and greater recyclability.

Cost Analysis: Bamboo Laminate vs Composite

Bamboo laminate typically costs less than bamboo composite due to simpler manufacturing processes and lower material requirements, making it a budget-friendly option for flooring and furniture. Bamboo composite incorporates additional resins and binding agents, increasing production expenses but offering enhanced durability and moisture resistance. Cost analysis shows that while bamboo laminate provides affordability, bamboo composite delivers longer-term value through improved lifespan and reduced maintenance costs.

Common Applications in Construction and Design

Bamboo laminate is commonly used in flooring, wall panels, and furniture due to its smooth finish and aesthetic appeal, providing strength and flexibility ideal for interior design elements. Bamboo composite, made by combining bamboo fibers with resin or other materials, is favored in structural applications such as decking, cabinetry, and exterior cladding for its enhanced durability and resistance to moisture. Both materials leverage bamboo's eco-friendly properties but differ in strength, moisture resistance, and texture, influencing their suitability for various construction and design projects.

Choosing the Right Bamboo Material for Your Project

Bamboo laminate offers a smooth, durable surface ideal for furniture and flooring, featuring layers of pressed bamboo fibers for enhanced strength. Bamboo composite combines bamboo fibers with resin or other binders, providing superior moisture resistance and structural stability, making it suitable for outdoor or high-humidity environments. Selecting the right bamboo material depends on your project's exposure to elements and desired aesthetic, with laminate favored for indoor use and composite excelling in demanding or wet conditions.

Bamboo laminate vs bamboo composite Infographic

materialdif.com

materialdif.com