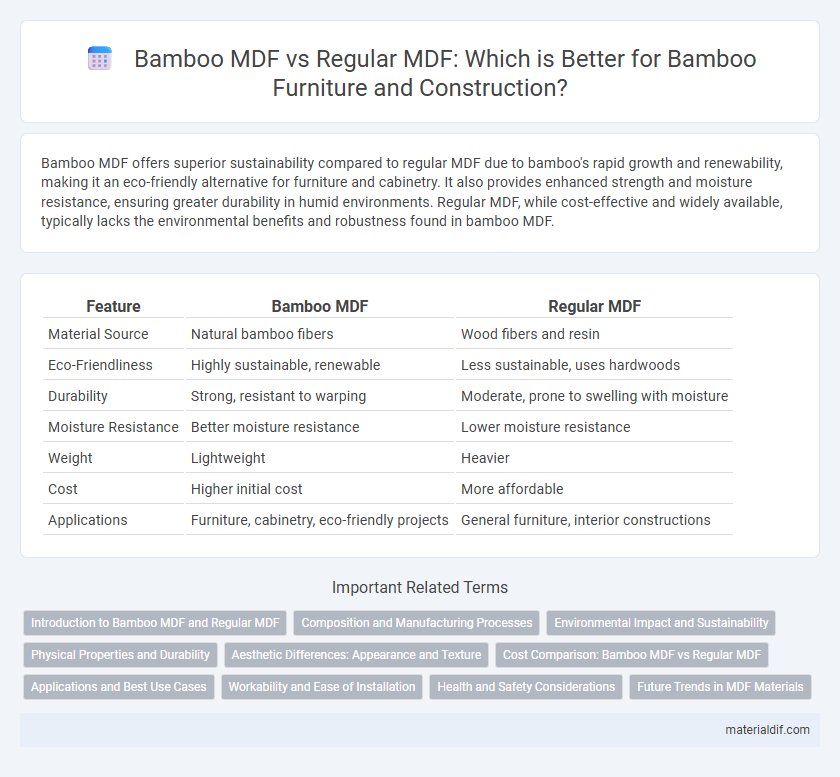

Bamboo MDF offers superior sustainability compared to regular MDF due to bamboo's rapid growth and renewability, making it an eco-friendly alternative for furniture and cabinetry. It also provides enhanced strength and moisture resistance, ensuring greater durability in humid environments. Regular MDF, while cost-effective and widely available, typically lacks the environmental benefits and robustness found in bamboo MDF.

Table of Comparison

| Feature | Bamboo MDF | Regular MDF |

|---|---|---|

| Material Source | Natural bamboo fibers | Wood fibers and resin |

| Eco-Friendliness | Highly sustainable, renewable | Less sustainable, uses hardwoods |

| Durability | Strong, resistant to warping | Moderate, prone to swelling with moisture |

| Moisture Resistance | Better moisture resistance | Lower moisture resistance |

| Weight | Lightweight | Heavier |

| Cost | Higher initial cost | More affordable |

| Applications | Furniture, cabinetry, eco-friendly projects | General furniture, interior constructions |

Introduction to Bamboo MDF and Regular MDF

Bamboo MDF is engineered from compressed bamboo fibers, offering a sustainable alternative to traditional Medium Density Fiberboard (MDF), which is primarily made from wood fibers and resin. Bamboo MDF provides greater durability and environmental benefits due to bamboo's rapid growth and renewability. Regular MDF, while widely used for furniture and cabinetry, tends to have higher formaldehyde emissions and lower moisture resistance compared to bamboo MDF.

Composition and Manufacturing Processes

Bamboo MDF is composed primarily of bamboo fibers, which are processed through a high-temperature steam treatment that enhances durability and natural resistance to moisture and insects, distinguishing it from regular MDF made from hardwood or softwood fibers. The manufacturing process of bamboo MDF involves crushing bamboo stalks into fibers, bonding them with eco-friendly resins, and pressing them into dense, uniform panels, resulting in a more sustainable and renewable product. Regular MDF production relies on wood chips and sawdust combined with synthetic resins, pressed under heat and pressure, often leading to higher environmental impact due to the use of non-renewable timber.

Environmental Impact and Sustainability

Bamboo MDF offers a significantly lower environmental impact compared to regular MDF due to its rapid growth rate and renewable nature, allowing for quicker carbon sequestration and reduced deforestation. Unlike traditional MDF, which relies on hardwood trees that take decades to mature, bamboo regenerates within 3-5 years, promoting sustainable forestry and minimizing habitat disruption. Bamboo MDF also emits fewer volatile organic compounds (VOCs) during production, enhancing indoor air quality and aligning with eco-friendly building standards.

Physical Properties and Durability

Bamboo MDF exhibits superior physical properties compared to regular MDF, including higher density and enhanced strength due to the natural fibers of bamboo, which contribute to its improved load-bearing capacity. Its durability surpasses that of conventional MDF, demonstrating better resistance to moisture, warping, and impact, making it ideal for high-traffic or humid environments. The natural antimicrobial properties of bamboo further extend the lifespan of bamboo MDF, providing a sustainable and resilient alternative to standard MDF products.

Aesthetic Differences: Appearance and Texture

Bamboo MDF features a natural, organic appearance with visible bamboo grain patterns, offering a unique texture that contrasts with the uniform, smooth surface of regular MDF. The light honey tones of bamboo MDF provide a warmer, more eco-friendly aesthetic compared to the typically flat, painted or laminated finish of conventional MDF. This distinct visual and tactile quality makes bamboo MDF an attractive choice for sustainable interior design projects seeking a natural look.

Cost Comparison: Bamboo MDF vs Regular MDF

Bamboo MDF typically costs 20-30% more than regular MDF due to its sustainable sourcing and eco-friendly manufacturing process. Regular MDF, made from softwood fibers and resin, remains more economical for large-scale construction and furniture projects. Despite the higher price, bamboo MDF offers increased durability and moisture resistance, potentially reducing long-term maintenance expenses.

Applications and Best Use Cases

Bamboo MDF offers superior durability and moisture resistance compared to regular MDF, making it ideal for applications in kitchens, bathrooms, and high-humidity environments. Its natural bamboo fibers provide enhanced strength for furniture, cabinetry, and flooring, delivering eco-friendly alternatives without compromising performance. Regular MDF remains suitable for general interior projects like molding and decorative paneling where high moisture resistance is less critical.

Workability and Ease of Installation

Bamboo MDF offers superior workability compared to regular MDF due to its denser, yet more flexible fibers, allowing for cleaner cuts and smoother sanding. Its natural resistance to moisture reduces the risk of swelling during installation, enhancing overall ease and durability in various environments. Installers benefit from bamboo MDF's lightweight structure, which simplifies handling and reduces labor time without compromising stability.

Health and Safety Considerations

Bamboo MDF offers superior health and safety benefits compared to regular MDF due to its natural resistance to moisture and mold, reducing indoor air quality risks. Unlike traditional MDF, which often contains formaldehyde-based resins linked to respiratory issues, bamboo MDF can be manufactured with low-emission adhesives, enhancing indoor environmental safety. The renewable nature of bamboo also minimizes exposure to harmful chemicals commonly used in synthetic wood products, making bamboo MDF a safer choice for both installers and occupants.

Future Trends in MDF Materials

Bamboo MDF is emerging as a sustainable alternative to regular MDF due to its rapid renewability and superior strength-to-weight ratio, which supports eco-friendly construction and furniture industries. Future trends in MDF materials highlight increased adoption of bio-based adhesives and resin-free manufacturing processes to reduce formaldehyde emissions and enhance indoor air quality. Innovations in bamboo fiber treatments and hybrid composites are expected to improve durability and moisture resistance, positioning bamboo MDF as a key material in green building certifications and circular economy models.

bamboo MDF vs regular MDF Infographic

materialdif.com

materialdif.com