Bamboo textile is a soft, breathable fabric derived from bamboo fibers, prized for its moisture-wicking and antibacterial properties, making it ideal for clothing and home textiles. Bamboo composite, on the other hand, combines bamboo fibers with resins or polymers to create durable, eco-friendly materials used in construction, furniture, and automotive parts. Both materials leverage bamboo's sustainability, but bamboo textile emphasizes comfort and wearability, while bamboo composite focuses on strength and versatility.

Table of Comparison

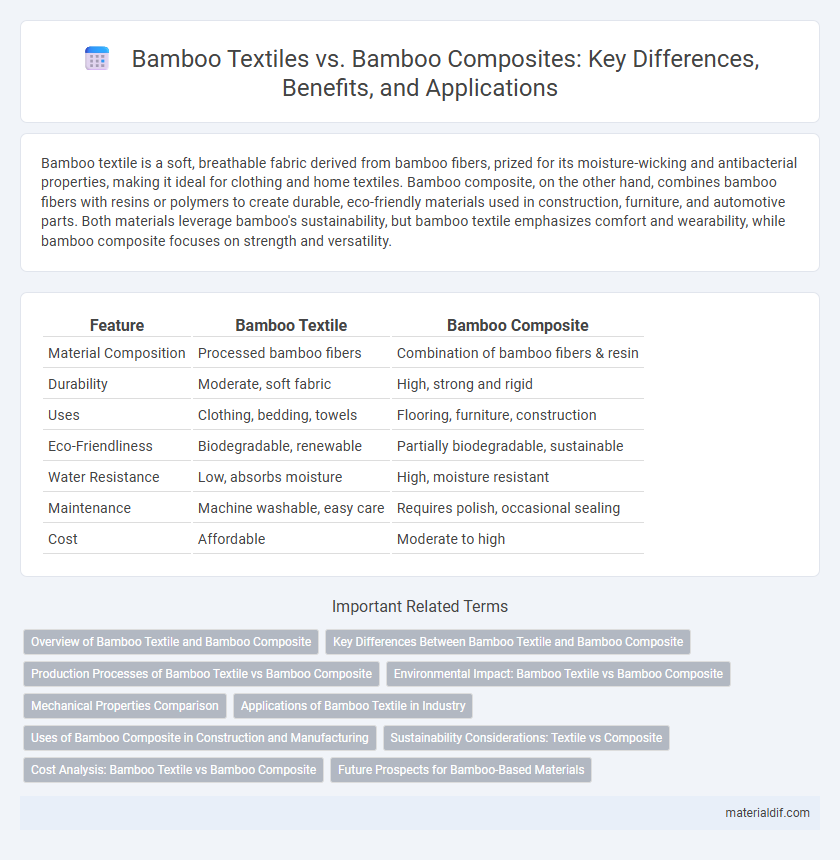

| Feature | Bamboo Textile | Bamboo Composite |

|---|---|---|

| Material Composition | Processed bamboo fibers | Combination of bamboo fibers & resin |

| Durability | Moderate, soft fabric | High, strong and rigid |

| Uses | Clothing, bedding, towels | Flooring, furniture, construction |

| Eco-Friendliness | Biodegradable, renewable | Partially biodegradable, sustainable |

| Water Resistance | Low, absorbs moisture | High, moisture resistant |

| Maintenance | Machine washable, easy care | Requires polish, occasional sealing |

| Cost | Affordable | Moderate to high |

Overview of Bamboo Textile and Bamboo Composite

Bamboo textile is a sustainable fabric derived from bamboo fibers through mechanical or chemical processing, valued for its softness, breathability, and antibacterial properties, making it ideal for clothing and home textiles. Bamboo composite, on the other hand, combines bamboo fibers with resins or polymers to create strong, lightweight materials used in construction, automotive, and furniture applications. Both forms leverage bamboo's rapid growth and renewable nature, but the textile emphasizes comfort and wearability while the composite focuses on structural strength and durability.

Key Differences Between Bamboo Textile and Bamboo Composite

Bamboo textile is a natural fiber made from the cellulose extracted from bamboo pulp, primarily used in soft, breathable fabrics for clothing and home textiles. Bamboo composite, on the other hand, is a engineered material combining bamboo fibers with resins or polymers, providing enhanced durability and strength for construction, furniture, and automotive applications. Key differences lie in their production methods, end-use applications, and physical properties, with bamboo textile emphasizing comfort and sustainability, while bamboo composite focuses on structural integrity and versatility.

Production Processes of Bamboo Textile vs Bamboo Composite

Bamboo textile production involves harvesting bamboo stalks, breaking them down into fibers through mechanical or chemical processes, and then spinning these fibers into yarns used for fabric manufacturing. In contrast, bamboo composite production integrates bamboo strips or fibers with resins or adhesives, undergoing processes like lamination or molding to create structural materials. The textile process emphasizes fiber extraction and softening for clothing applications, whereas composite production focuses on bonding and curing techniques to produce durable, load-bearing components.

Environmental Impact: Bamboo Textile vs Bamboo Composite

Bamboo textile production uses natural fibers derived from bamboo plants, requiring less water and pesticides compared to traditional cotton, making it a more sustainable fabric choice with lower carbon emissions. Bamboo composites, combining bamboo fibers with resins, offer high strength and durability but often involve synthetic adhesives that can hinder biodegradability and increase the environmental footprint. Overall, bamboo textiles tend to have a gentler environmental impact due to their renewable sourcing and lower chemical processing, while bamboo composites present trade-offs between structural benefits and eco-friendliness depending on resin composition.

Mechanical Properties Comparison

Bamboo textiles exhibit high tensile strength and flexibility, ideal for apparel and soft goods, with fibers characterized by a modulus of elasticity around 38 GPa and elongation at break near 3.5%. Bamboo composites, reinforced with bamboo fibers embedded in resin matrices, demonstrate superior mechanical properties including enhanced stiffness, impact resistance, and load-bearing capabilities, reaching flexural strengths upwards of 100 MPa and tensile moduli exceeding 20 GPa depending on composite formulation. The anisotropic nature and density of bamboo fibers contribute to these mechanical differences, making composites suitable for structural applications while textiles excel in lightweight, breathable uses.

Applications of Bamboo Textile in Industry

Bamboo textile, derived from bamboo fibers, is extensively used in the fashion and interior design industries due to its softness, breathability, and natural antibacterial properties. This sustainable fabric is favored for producing eco-friendly clothing, activewear, bedding, and upholstery, offering both comfort and durability. Unlike bamboo composites, which are primarily used in construction and automotive sectors for their strength and rigidity, bamboo textiles excel in applications requiring flexibility and moisture management.

Uses of Bamboo Composite in Construction and Manufacturing

Bamboo composite is extensively used in construction and manufacturing due to its high strength-to-weight ratio and sustainability. It serves as an eco-friendly alternative for flooring, paneling, and structural elements, offering enhanced durability and resistance to moisture compared to traditional bamboo textiles. The composite's engineered properties make it ideal for furniture production, automotive components, and building frameworks, promoting green building practices and reducing reliance on synthetic materials.

Sustainability Considerations: Textile vs Composite

Bamboo textile production involves processing bamboo fibers into fabric, which is biodegradable and renewable, contributing to reduced environmental impact compared to synthetic fibers. In contrast, bamboo composites combine bamboo fibers with resins or plastics, enhancing durability but often compromising biodegradability due to non-biodegradable matrix materials. Evaluating sustainability requires balancing bamboo textile's lower ecological footprint and compostability against bamboo composite's longer lifespan and material efficiency in structural applications.

Cost Analysis: Bamboo Textile vs Bamboo Composite

Bamboo textile production typically incurs lower raw material costs due to its direct processing from bamboo fibers, whereas bamboo composites demand higher expenses related to resin binders and advanced manufacturing techniques. The labor-intensive processes and energy consumption in creating bamboo composites further elevate their overall cost compared to bamboo textiles. Despite higher upfront costs, bamboo composites offer enhanced durability and structural benefits, influencing long-term value assessments.

Future Prospects for Bamboo-Based Materials

Bamboo textile and bamboo composite materials both present sustainable alternatives with distinct future prospects driven by increasing demand for eco-friendly construction and fashion industries. Bamboo textiles offer biodegradable, breathable fabric solutions that appeal to environmentally conscious consumers seeking comfort and durability in clothing. Meanwhile, bamboo composites demonstrate significant potential in automotive, aerospace, and building sectors due to their high strength-to-weight ratio, renewable sourcing, and carbon sequestration properties.

Bamboo textile vs bamboo composite Infographic

materialdif.com

materialdif.com