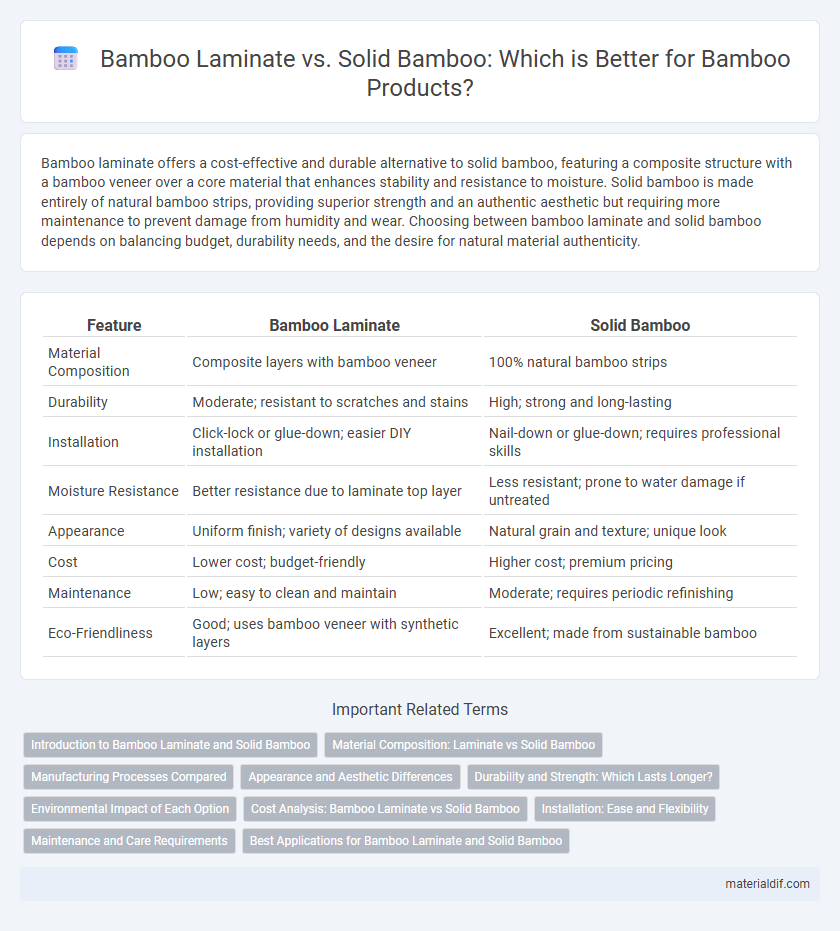

Bamboo laminate offers a cost-effective and durable alternative to solid bamboo, featuring a composite structure with a bamboo veneer over a core material that enhances stability and resistance to moisture. Solid bamboo is made entirely of natural bamboo strips, providing superior strength and an authentic aesthetic but requiring more maintenance to prevent damage from humidity and wear. Choosing between bamboo laminate and solid bamboo depends on balancing budget, durability needs, and the desire for natural material authenticity.

Table of Comparison

| Feature | Bamboo Laminate | Solid Bamboo |

|---|---|---|

| Material Composition | Composite layers with bamboo veneer | 100% natural bamboo strips |

| Durability | Moderate; resistant to scratches and stains | High; strong and long-lasting |

| Installation | Click-lock or glue-down; easier DIY installation | Nail-down or glue-down; requires professional skills |

| Moisture Resistance | Better resistance due to laminate top layer | Less resistant; prone to water damage if untreated |

| Appearance | Uniform finish; variety of designs available | Natural grain and texture; unique look |

| Cost | Lower cost; budget-friendly | Higher cost; premium pricing |

| Maintenance | Low; easy to clean and maintain | Moderate; requires periodic refinishing |

| Eco-Friendliness | Good; uses bamboo veneer with synthetic layers | Excellent; made from sustainable bamboo |

Introduction to Bamboo Laminate and Solid Bamboo

Bamboo laminate consists of thin layers of bamboo fibers bonded together under high pressure, offering enhanced durability and resistance to moisture compared to solid bamboo, which is made from natural, solid strips of bamboo culms. Solid bamboo features a dense, uniform structure with natural grain patterns, making it ideal for applications requiring strength and aesthetic appeal. Both materials provide eco-friendly alternatives to traditional hardwood, with laminate excelling in stability and solid bamboo favored for its natural texture and robustness.

Material Composition: Laminate vs Solid Bamboo

Bamboo laminate consists of thin layers of bamboo fibers fused together with adhesive resin, creating a composite material that offers enhanced durability and moisture resistance compared to solid bamboo. Solid bamboo is made from natural bamboo strips compressed and fused without additional layers, maintaining its organic structure and providing a more authentic appearance and feel. The laminate's engineered composition allows for greater stability and uniformity, while solid bamboo emphasizes natural aesthetics and environmental sustainability.

Manufacturing Processes Compared

Bamboo laminate is produced by slicing bamboo stalks into thin veneers, which are then glued and pressed together under high heat and pressure, resulting in a more uniform and moisture-resistant product. Solid bamboo involves compressing strips of natural bamboo culms without layering, retaining more of the raw material's natural texture and strength but offering less stability against humidity changes. Manufacturing processes for bamboo laminate typically allow for greater control over thickness and finish, while solid bamboo emphasizes a more natural aesthetic with simpler production steps.

Appearance and Aesthetic Differences

Bamboo laminate features a smoother, more uniform surface with consistent color and pattern, making it ideal for modern, sleek designs. Solid bamboo showcases natural grain variations and texture, offering a warm, organic appearance with unique knots and stripes. The choice between laminate and solid bamboo significantly impacts the overall visual character and authenticity of the flooring or furniture.

Durability and Strength: Which Lasts Longer?

Bamboo laminate offers enhanced scratch resistance and moisture protection due to its multi-layer construction, making it highly durable for high-traffic areas. Solid bamboo boasts superior natural strength and density, providing robust resistance to dents and impacts over time. While solid bamboo tends to last longer under heavy use, laminate flooring delivers consistent durability with easier maintenance, making both suitable depending on the specific durability needs.

Environmental Impact of Each Option

Bamboo laminate is produced by compressing thin layers of bamboo fibers with adhesives, which can involve the use of synthetic resins that may emit VOCs, slightly increasing its environmental footprint. Solid bamboo, made from whole bamboo stalks, typically requires less processing and fewer chemicals, resulting in lower emissions and a smaller carbon footprint. Both options are renewable and biodegradable, but solid bamboo generally offers a more environmentally friendly choice due to its minimal processing and reduced chemical use.

Cost Analysis: Bamboo Laminate vs Solid Bamboo

Bamboo laminate typically costs 20-40% less than solid bamboo due to its engineered construction using thin bamboo veneers fused with adhesive layers, reducing raw material usage. Solid bamboo involves higher manufacturing expenses from sourcing whole bamboo stalks and intricate processing, resulting in a premium price point. Cost analysis favors bamboo laminate for budget-conscious projects, while solid bamboo provides longer-lasting durability despite increased initial investment.

Installation: Ease and Flexibility

Bamboo laminate offers easier installation with click-lock or tongue-and-groove systems, making it suitable for DIY projects and uneven subfloors, while solid bamboo requires professional installation and precise subfloor preparation. Laminate is more flexible, allowing it to expand and contract with humidity changes without warping, unlike solid bamboo which is prone to movement and needs acclimation. The choice between bamboo laminate and solid bamboo impacts installation time, cost, and long-term floor stability.

Maintenance and Care Requirements

Bamboo laminate requires minimal maintenance, needing only regular dusting and occasional damp mopping to keep its surface clean and free from scratches or water damage. Solid bamboo demands more careful upkeep, including periodic sealing or oiling to maintain moisture resistance and prevent warping or cracking over time. Both materials benefit from avoiding excessive exposure to water and direct sunlight to ensure longevity and aesthetic appeal.

Best Applications for Bamboo Laminate and Solid Bamboo

Bamboo laminate is ideal for high-traffic areas such as commercial flooring and kitchen countertops due to its enhanced durability and resistance to scratches and moisture. Solid bamboo excels in furniture making and decorative woodworking where natural aesthetics and structural integrity are prioritized. Both materials offer eco-friendly benefits, but selecting between laminate and solid bamboo depends on the specific application's demand for strength, appearance, and maintenance.

Bamboo laminate vs solid bamboo Infographic

materialdif.com

materialdif.com