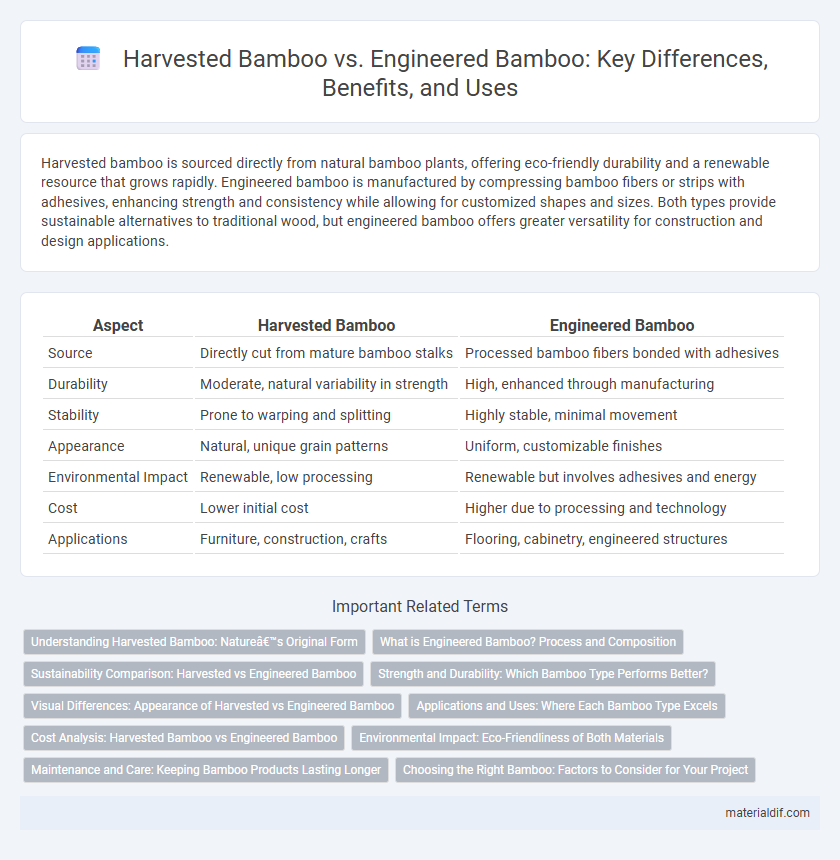

Harvested bamboo is sourced directly from natural bamboo plants, offering eco-friendly durability and a renewable resource that grows rapidly. Engineered bamboo is manufactured by compressing bamboo fibers or strips with adhesives, enhancing strength and consistency while allowing for customized shapes and sizes. Both types provide sustainable alternatives to traditional wood, but engineered bamboo offers greater versatility for construction and design applications.

Table of Comparison

| Aspect | Harvested Bamboo | Engineered Bamboo |

|---|---|---|

| Source | Directly cut from mature bamboo stalks | Processed bamboo fibers bonded with adhesives |

| Durability | Moderate, natural variability in strength | High, enhanced through manufacturing |

| Stability | Prone to warping and splitting | Highly stable, minimal movement |

| Appearance | Natural, unique grain patterns | Uniform, customizable finishes |

| Environmental Impact | Renewable, low processing | Renewable but involves adhesives and energy |

| Cost | Lower initial cost | Higher due to processing and technology |

| Applications | Furniture, construction, crafts | Flooring, cabinetry, engineered structures |

Understanding Harvested Bamboo: Nature’s Original Form

Harvested bamboo is the natural, raw form of bamboo collected directly from forests or plantations, preserving its organic structure and strength. This type retains all natural fibers, moisture content, and unique grain patterns, essential for traditional uses and sustainable applications. Understanding harvested bamboo helps in appreciating its durability, flexibility, and ecological benefits compared to engineered bamboo products.

What is Engineered Bamboo? Process and Composition

Engineered bamboo is a sustainable construction material created by processing harvested bamboo into laminated or compressed forms to enhance strength and durability. The production involves splitting, flattening, laminating bamboo strips with adhesives, and pressing them under heat to form boards or panels with consistent density and resistance properties. This process combines natural bamboo fibers with resins, resulting in high-performance products used in flooring, furniture, and structural applications.

Sustainability Comparison: Harvested vs Engineered Bamboo

Harvested bamboo is a rapidly renewable resource known for its fast growth cycle and minimal environmental impact during harvesting, making it highly sustainable. Engineered bamboo, created by processing harvested bamboo fibers into composite materials, can offer enhanced durability and structural performance but often involves energy-intensive manufacturing processes and chemical adhesives, which may reduce its overall eco-friendliness. Comparing sustainability, harvested bamboo scores higher in carbon sequestration and biodegradability, whereas engineered bamboo provides long-lasting products with potentially greater carbon footprints due to production methods.

Strength and Durability: Which Bamboo Type Performs Better?

Harvested bamboo retains its natural fibers, offering high tensile strength and excellent durability for traditional construction uses. Engineered bamboo improves consistency and resistance to environmental factors through processing, often surpassing raw bamboo in structural performance. While harvested bamboo excels in natural flexibility, engineered bamboo provides enhanced strength and longevity, making it preferable for long-term, heavy-load applications.

Visual Differences: Appearance of Harvested vs Engineered Bamboo

Harvested bamboo retains its natural grain variations, knots, and color gradients, showcasing an organic and authentic appearance with unique texture patterns. Engineered bamboo features a more uniform and consistent look due to the lamination and processing techniques that align strands or layers for enhanced durability. The visual differences highlight harvested bamboo's rustic charm versus engineered bamboo's polished, sleek aesthetic suitable for modern design applications.

Applications and Uses: Where Each Bamboo Type Excels

Harvested bamboo is ideal for traditional construction, furniture, and craft applications due to its natural strength, flexibility, and aesthetic appeal, making it popular in eco-friendly building and decorative elements. Engineered bamboo, processed into laminated boards or panels, provides enhanced durability, uniformity, and resistance to moisture, making it the preferred choice for flooring, cabinetry, and structural components requiring precision and long-term performance. Each type's unique characteristics allow harvested bamboo to excel in artisanal, natural uses, while engineered bamboo dominates modern architectural and interior design projects.

Cost Analysis: Harvested Bamboo vs Engineered Bamboo

Harvested bamboo typically incurs lower initial costs due to minimal processing requirements and direct sourcing from natural groves, making it an economical choice for raw material needs. Engineered bamboo involves advanced manufacturing techniques such as lamination and adhesive bonding, which elevate production expenses but enhance durability and structural integrity. When evaluating cost efficiency, harvested bamboo is favorable for budget-sensitive projects, while engineered bamboo offers long-term value through increased performance and lifespan.

Environmental Impact: Eco-Friendliness of Both Materials

Harvested bamboo is highly eco-friendly due to its rapid growth rate and carbon sequestration abilities, making it a sustainable raw material with minimal environmental degradation. Engineered bamboo, while utilizing harvested bamboo fibers, incorporates adhesives and manufacturing processes that may introduce chemical emissions and increase its carbon footprint compared to raw bamboo. Both materials contribute to reducing deforestation impacts, but harvested bamboo stands out for its lower environmental impact and biodegradability.

Maintenance and Care: Keeping Bamboo Products Lasting Longer

Harvested bamboo requires regular sealing and protection from moisture to prevent warping and insect damage, ensuring its natural fibers remain strong and durable. Engineered bamboo incorporates adhesives and treatments that enhance resistance to wear and environmental stress, reducing the frequency of maintenance compared to raw bamboo. Proper cleaning routines and avoiding prolonged exposure to water extend the lifespan of both harvested and engineered bamboo products.

Choosing the Right Bamboo: Factors to Consider for Your Project

Harvested bamboo offers natural strength and eco-friendly benefits, making it ideal for sustainable construction and furniture projects that require raw, untreated material. Engineered bamboo, processed into strands, panels, or laminated blocks, provides enhanced durability, uniformity, and resistance to moisture, suitable for flooring, cabinetry, and structural applications. Consider project requirements such as load-bearing capacity, exposure to elements, aesthetic preferences, and environmental impact when selecting between harvested and engineered bamboo.

Harvested bamboo vs Engineered bamboo Infographic

materialdif.com

materialdif.com