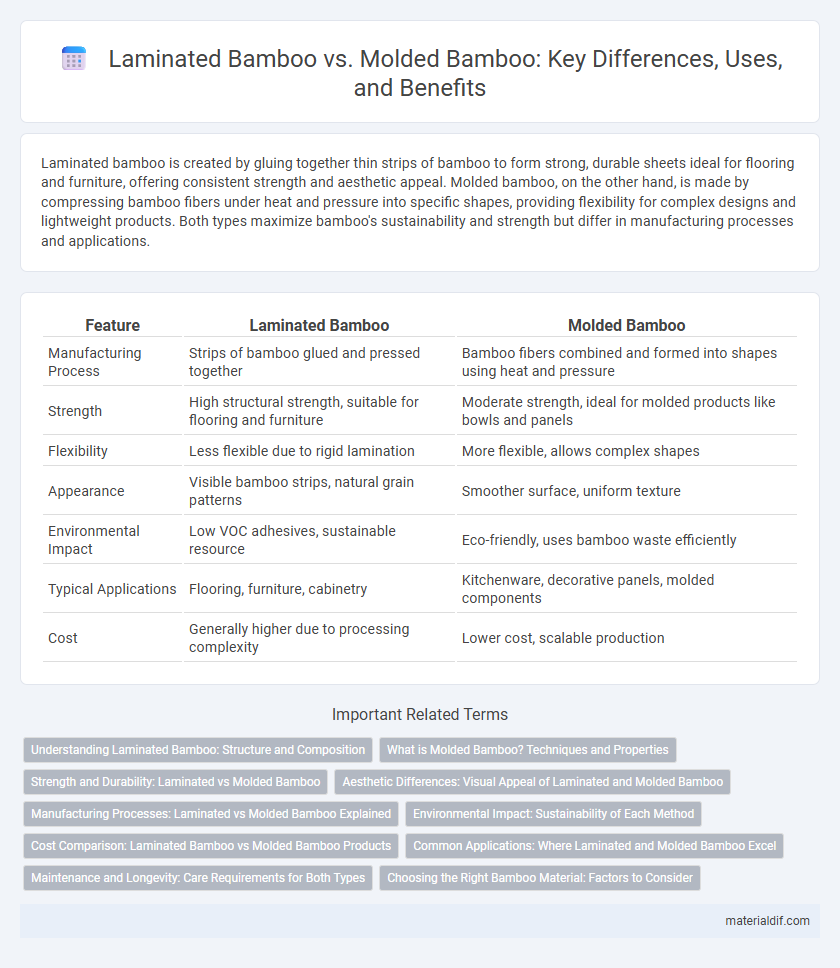

Laminated bamboo is created by gluing together thin strips of bamboo to form strong, durable sheets ideal for flooring and furniture, offering consistent strength and aesthetic appeal. Molded bamboo, on the other hand, is made by compressing bamboo fibers under heat and pressure into specific shapes, providing flexibility for complex designs and lightweight products. Both types maximize bamboo's sustainability and strength but differ in manufacturing processes and applications.

Table of Comparison

| Feature | Laminated Bamboo | Molded Bamboo |

|---|---|---|

| Manufacturing Process | Strips of bamboo glued and pressed together | Bamboo fibers combined and formed into shapes using heat and pressure |

| Strength | High structural strength, suitable for flooring and furniture | Moderate strength, ideal for molded products like bowls and panels |

| Flexibility | Less flexible due to rigid lamination | More flexible, allows complex shapes |

| Appearance | Visible bamboo strips, natural grain patterns | Smoother surface, uniform texture |

| Environmental Impact | Low VOC adhesives, sustainable resource | Eco-friendly, uses bamboo waste efficiently |

| Typical Applications | Flooring, furniture, cabinetry | Kitchenware, decorative panels, molded components |

| Cost | Generally higher due to processing complexity | Lower cost, scalable production |

Understanding Laminated Bamboo: Structure and Composition

Laminated bamboo consists of multiple thin bamboo strips bonded together with strong adhesives, creating a dense, durable, and stable material ideal for flooring and furniture. This engineered structure enhances strength by aligning bamboo fibers parallel to each other, reducing weaknesses found in natural bamboo. Its layered composition allows for consistent quality control and resistance to warping compared to molded bamboo, which is formed by pressing bamboo fibers into molds.

What is Molded Bamboo? Techniques and Properties

Molded bamboo is created by compressing bamboo fibers mixed with adhesives into molds under heat and pressure, resulting in durable, lightweight, and flexible products with complex shapes. This technique preserves the natural strength of bamboo while allowing for innovative designs that are difficult to achieve with laminated bamboo, which involves layering bamboo strips bonded with adhesives. Molded bamboo offers enhanced moisture resistance and impact strength, making it ideal for applications in furniture, automotive components, and sustainable packaging.

Strength and Durability: Laminated vs Molded Bamboo

Laminated bamboo, created by layering thin bamboo strips with strong adhesive resins, offers superior strength and durability due to its cross-grain construction minimizing warping and splitting. Molded bamboo, formed by compressing bamboo fibers and binders into shapes, tends to be less robust and more prone to deformation under heavy loads or prolonged stress. The density and structural integrity of laminated bamboo make it ideal for applications requiring high load-bearing capacity and long-term resilience.

Aesthetic Differences: Visual Appeal of Laminated and Molded Bamboo

Laminated bamboo showcases a linear and uniform grain pattern, creating a sleek, modern aesthetic ideal for contemporary interiors, while molded bamboo offers a smoother, more organic look with subtle curves and textures that highlight natural variations. The visual appeal of laminated bamboo often emphasizes structural clarity and consistency, contrasting with the softer, sculptural qualities of molded bamboo that evoke handcrafted artistry. Choosing between laminated and molded bamboo depends on whether the design prioritizes geometric precision or fluid, natural forms.

Manufacturing Processes: Laminated vs Molded Bamboo Explained

Laminated bamboo is created by slicing bamboo into thin strips, drying, and then bonding them with adhesives under heat and pressure to form sturdy, layered boards. Molded bamboo involves grinding bamboo fibers into a pulp, mixing with adhesives, and then compressing the mixture into shapes using molds, allowing for more intricate designs. The laminated process emphasizes strength and uniformity, while molded bamboo offers greater flexibility in form and texture.

Environmental Impact: Sustainability of Each Method

Laminated bamboo is created by bonding thin strips of bamboo with adhesives, offering high strength but often involving synthetic resins that may affect its eco-friendliness. Molded bamboo is produced by compressing bamboo fibers with natural binders under heat and pressure, reducing the reliance on harmful chemicals and enhancing biodegradability. Both methods utilize bamboo's rapid renewability, but molded bamboo typically presents a lower environmental footprint due to minimal use of synthetic substances.

Cost Comparison: Laminated Bamboo vs Molded Bamboo Products

Laminated bamboo products typically cost more than molded bamboo due to the labor-intensive process of layering and bonding bamboo strips, which enhances strength and durability. Molded bamboo, created by compressing bamboo fibers with resins into molds, generally offers a more cost-effective option for mass production and complex shapes. Price differences also reflect variations in quality, with laminated bamboo preferred for furniture and flooring, while molded bamboo suits budget-friendly decorative items and lightweight applications.

Common Applications: Where Laminated and Molded Bamboo Excel

Laminated bamboo excels in applications requiring high strength and durability, such as flooring, furniture, and architectural panels, due to its layered construction that enhances stability and resistance to warping. Molded bamboo is ideal for curved or ergonomic designs like chair shells, utensils, and decorative items, benefiting from its ability to be shaped into complex forms through heat and pressure molding techniques. Both types leverage bamboo's renewable qualities, making them popular choices in eco-friendly construction and sustainable product design.

Maintenance and Longevity: Care Requirements for Both Types

Laminated bamboo requires regular cleaning with a damp cloth and occasional polishing to maintain its finish, while molded bamboo benefits from gentle wiping and drying to prevent moisture damage. Both types exhibit high durability, but laminated bamboo generally offers greater resistance to scratches and wear due to its layered construction. Proper maintenance extends the lifespan of both materials, with laminated bamboo typically lasting 15-25 years and molded bamboo around 10-15 years under optimal care conditions.

Choosing the Right Bamboo Material: Factors to Consider

Laminated bamboo offers superior strength and uniformity due to its multiple layers glued together, making it ideal for flooring and furniture that require durability. Molded bamboo, shaped by heat and pressure from bamboo fibers, provides greater flexibility and design variety, suitable for curved surfaces and intricate forms. When choosing the right bamboo material, consider factors such as load-bearing capacity, aesthetic preferences, environmental impact, and specific application requirements.

Laminated bamboo vs molded bamboo Infographic

materialdif.com

materialdif.com