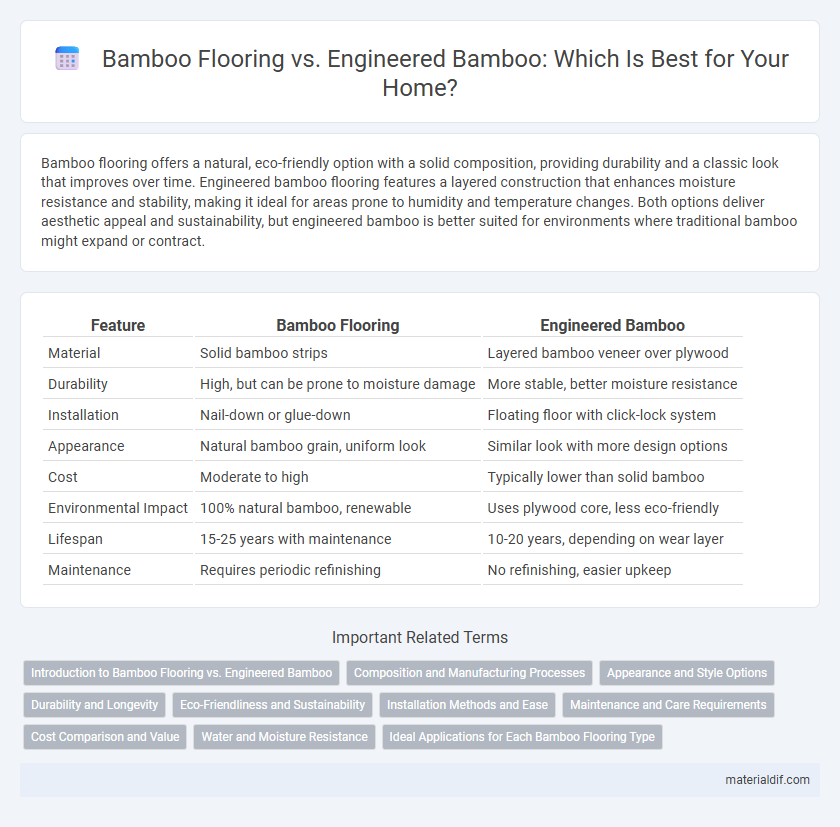

Bamboo flooring offers a natural, eco-friendly option with a solid composition, providing durability and a classic look that improves over time. Engineered bamboo flooring features a layered construction that enhances moisture resistance and stability, making it ideal for areas prone to humidity and temperature changes. Both options deliver aesthetic appeal and sustainability, but engineered bamboo is better suited for environments where traditional bamboo might expand or contract.

Table of Comparison

| Feature | Bamboo Flooring | Engineered Bamboo |

|---|---|---|

| Material | Solid bamboo strips | Layered bamboo veneer over plywood |

| Durability | High, but can be prone to moisture damage | More stable, better moisture resistance |

| Installation | Nail-down or glue-down | Floating floor with click-lock system |

| Appearance | Natural bamboo grain, uniform look | Similar look with more design options |

| Cost | Moderate to high | Typically lower than solid bamboo |

| Environmental Impact | 100% natural bamboo, renewable | Uses plywood core, less eco-friendly |

| Lifespan | 15-25 years with maintenance | 10-20 years, depending on wear layer |

| Maintenance | Requires periodic refinishing | No refinishing, easier upkeep |

Introduction to Bamboo Flooring vs. Engineered Bamboo

Bamboo flooring is made from solid bamboo strips, offering natural durability and a traditional hardwood feel, while engineered bamboo consists of a bamboo veneer layer fused to plywood or composite backing for enhanced stability. Solid bamboo flooring tends to be more susceptible to moisture and humidity changes, whereas engineered bamboo performs better in varying climates due to its layered construction. Both types provide eco-friendly alternatives to hardwood, with engineered bamboo often preferred for areas with temperature fluctuations or potential moisture exposure.

Composition and Manufacturing Processes

Bamboo flooring is typically made from solid strips of natural bamboo that are baked, sliced, and laminated to create durable planks, emphasizing traditional manufacturing methods. Engineered bamboo flooring consists of a top layer of bamboo veneer bonded to multiple core layers of plywood or high-density fiberboard, enhancing stability and moisture resistance. The manufacturing process of engineered bamboo involves advanced lamination techniques and cross-layering, which improve dimensional stability compared to solid bamboo flooring.

Appearance and Style Options

Bamboo flooring offers a classic, natural look with rich grain patterns and a warm, uniform tone, while engineered bamboo provides enhanced stability and a wider variety of styles, including strand-woven, horizontal, and vertical grains. Engineered bamboo can mimic traditional hardwood aesthetics more closely due to its layered construction and customizable finishes. Both options deliver eco-friendly appeal, but engineered bamboo expands design flexibility with varied plank widths and surface textures.

Durability and Longevity

Bamboo flooring offers impressive durability due to its natural hardness, often ranking higher on the Janka hardness scale compared to traditional hardwoods, making it resistant to dents and scratches. Engineered bamboo flooring combines a top layer of solid bamboo with a plywood base, enhancing dimensional stability and reducing susceptibility to warping in fluctuating humidity and temperature conditions. While solid bamboo flooring can last up to 25 years with proper maintenance, engineered bamboo often provides improved longevity in challenging environments, making it a preferred choice for areas with varying climate.

Eco-Friendliness and Sustainability

Bamboo flooring, made from solid bamboo strips, offers superior durability and natural eco-friendliness due to its rapid renewability and minimal processing. Engineered bamboo flooring consists of a bamboo veneer bonded to a plywood or HDF core, which can reduce the sustainable impact by incorporating less renewable materials and adhesives. Both types promote sustainability compared to traditional hardwoods, but solid bamboo flooring generally exhibits a smaller carbon footprint and better biodegradability.

Installation Methods and Ease

Bamboo flooring typically requires a nail-down or glue-down installation method, demanding a more experienced hand and extended preparation time. Engineered bamboo flooring features a click-lock or floating installation system, enabling faster and easier DIY application on various subfloors. The stability of engineered bamboo also reduces expansion and contraction issues, simplifying maintenance post-installation.

Maintenance and Care Requirements

Bamboo flooring requires regular sweeping and occasional damp mopping to prevent dirt buildup and moisture damage, while engineered bamboo offers enhanced moisture resistance and is easier to maintain in humid environments due to its multi-layer construction. Engineered bamboo floors tolerate temperature fluctuations better, reducing the likelihood of warping compared to solid bamboo. Both types benefit from using protective pads under furniture and avoiding harsh chemicals to maintain finish longevity.

Cost Comparison and Value

Bamboo flooring typically costs between $5 and $8 per square foot, offering a more affordable upfront investment compared to engineered bamboo, which ranges from $7 to $12 per square foot due to its composite construction. Engineered bamboo provides greater durability and moisture resistance, enhancing long-term value despite the higher initial price. Homeowners seeking budget-friendly options may prefer solid bamboo, while those prioritizing longevity and performance often find engineered bamboo to be a better investment.

Water and Moisture Resistance

Bamboo flooring offers good natural water resistance but can warp or swell with prolonged exposure to moisture, making it less ideal for high-humidity areas. Engineered bamboo flooring enhances moisture resistance by incorporating plywood layers and a stabilizing core, which reduces the risk of warping and improves dimensional stability. This construction makes engineered bamboo a more reliable choice for kitchens, bathrooms, and basements where moisture exposure is frequent.

Ideal Applications for Each Bamboo Flooring Type

Bamboo flooring offers superior durability and moisture resistance, making it ideal for high-traffic areas such as living rooms and kitchens where wear and tear are common. Engineered bamboo flooring features a layered construction that enhances stability and is better suited for basements and rooms with fluctuating humidity levels. Selecting the right bamboo flooring type depends on environmental conditions and the specific demands of the installation space.

Bamboo flooring vs Engineered bamboo Infographic

materialdif.com

materialdif.com