Bamboo rayon is produced through a chemically intensive process that breaks down bamboo fibers using harsh solvents, resulting in a softer but less eco-friendly fabric. Bamboo lyocell, on the other hand, involves a closed-loop system that recycles solvents and minimizes environmental impact, offering a more sustainable and breathable textile. Both materials showcase bamboo's versatility, but bamboo lyocell is preferred for its greener production and durability.

Table of Comparison

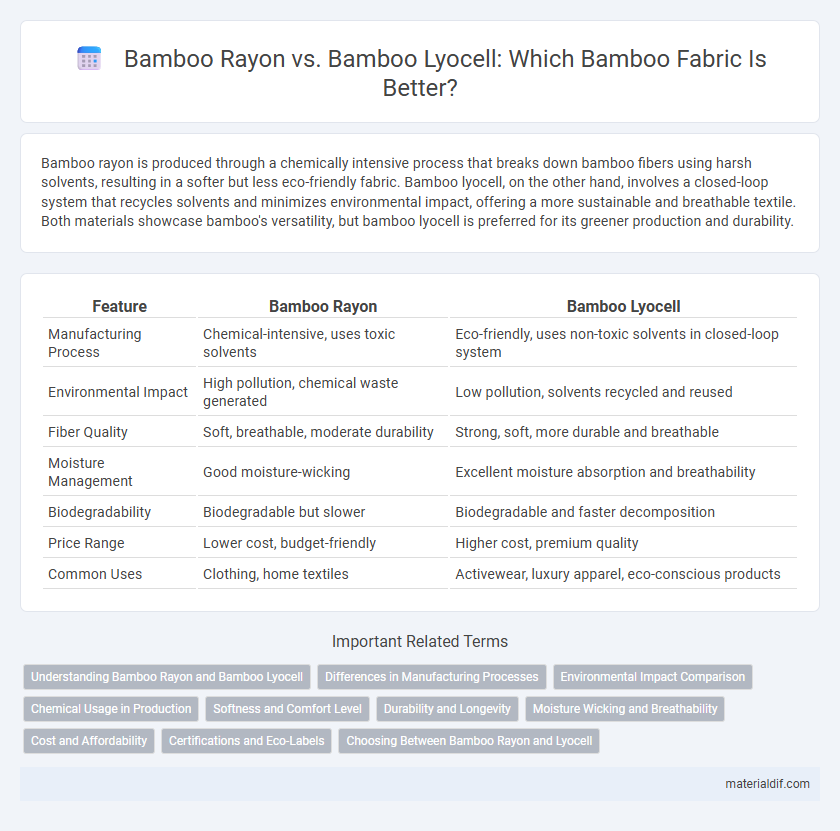

| Feature | Bamboo Rayon | Bamboo Lyocell |

|---|---|---|

| Manufacturing Process | Chemical-intensive, uses toxic solvents | Eco-friendly, uses non-toxic solvents in closed-loop system |

| Environmental Impact | High pollution, chemical waste generated | Low pollution, solvents recycled and reused |

| Fiber Quality | Soft, breathable, moderate durability | Strong, soft, more durable and breathable |

| Moisture Management | Good moisture-wicking | Excellent moisture absorption and breathability |

| Biodegradability | Biodegradable but slower | Biodegradable and faster decomposition |

| Price Range | Lower cost, budget-friendly | Higher cost, premium quality |

| Common Uses | Clothing, home textiles | Activewear, luxury apparel, eco-conscious products |

Understanding Bamboo Rayon and Bamboo Lyocell

Bamboo rayon is a semi-synthetic fiber produced through chemical processing that breaks down bamboo cellulose into a viscous solution before spinning it into fibers, which often involves the use of harmful chemicals like sodium hydroxide and carbon disulfide. Bamboo lyocell, on the other hand, utilizes a closed-loop solvent spinning process that recycles water and solvents, making it a more environmentally friendly option with higher tensile strength and moisture-wicking properties. Understanding these differences is crucial for choosing eco-conscious textiles, as bamboo lyocell offers sustainable production benefits and superior fabric performance compared to traditional bamboo rayon.

Differences in Manufacturing Processes

Bamboo rayon is produced through a chemically-intensive process that uses sodium hydroxide and carbon disulfide to convert bamboo cellulose into viscose fibers, often resulting in environmental concerns. Bamboo lyocell manufacturing employs a closed-loop solvent spinning method using non-toxic amine oxide, which recycles over 99% of the solvent, making it more eco-friendly. The key difference lies in the chemical treatments and environmental impact, with lyocell favored for sustainable production.

Environmental Impact Comparison

Bamboo rayon production relies on chemical solvents like carbon disulfide, generating toxic waste harmful to ecosystems and human health. Bamboo lyocell uses a closed-loop process that recycles solvents and significantly reduces water and energy consumption, minimizing its environmental footprint. The sustainable manufacturing of bamboo lyocell results in fewer pollutants and lower carbon emissions compared to traditional bamboo rayon.

Chemical Usage in Production

Bamboo rayon production involves heavy chemical use, including sodium hydroxide and carbon disulfide, which can pose environmental and health risks if not properly managed. Bamboo lyocell utilizes a closed-loop solvent spin process with non-toxic N-methylmorpholine N-oxide, significantly reducing chemical waste and pollution. This difference in chemical usage makes bamboo lyocell a more sustainable and eco-friendly fabric choice.

Softness and Comfort Level

Bamboo rayon and bamboo lyocell both offer exceptional softness, with bamboo lyocell often recognized for its smoother, silkier texture due to its eco-friendly closed-loop production process. Bamboo lyocell fibers provide enhanced breathability and moisture-wicking properties, resulting in superior comfort for sensitive skin. Bamboo rayon, while soft, may have a slightly rougher feel and less durability compared to the more refined bamboo lyocell fabric.

Durability and Longevity

Bamboo rayon tends to have lower durability due to the harsh chemical process used in its production, which weakens fibers and shortens the fabric's lifespan. Bamboo lyocell is produced with a closed-loop process that preserves the strength of cellulose fibers, resulting in increased durability and longer-lasting fabric. Bamboo lyocell's enhanced fiber integrity ensures garments maintain shape and softness through multiple washes, making it a more sustainable choice for longevity.

Moisture Wicking and Breathability

Bamboo rayon offers moderate moisture-wicking properties but tends to retain more moisture compared to bamboo lyocell, which excels in pulling sweat away from the skin due to its advanced fiber structure. Bamboo lyocell's superior breathability enhances airflow, making it more effective at keeping the body cool and dry during physical activity. This distinction arises from the lyocell production process, which preserves the natural qualities of bamboo fibers, resulting in better moisture management and comfort.

Cost and Affordability

Bamboo rayon is generally more affordable than bamboo lyocell due to its simpler and less environmentally friendly manufacturing process, which reduces production costs. Bamboo lyocell involves a closed-loop system that uses non-toxic solvents, making it more expensive but also more sustainable. Consumers prioritizing cost-effectiveness often choose bamboo rayon, while those seeking eco-friendly options are willing to invest in the higher-priced bamboo lyocell.

Certifications and Eco-Labels

Bamboo rayon and bamboo lyocell differ significantly in certifications and eco-labels, with bamboo lyocell often earning more environmentally recognized credentials such as OEKO-TEX Standard 100 and FSC certification for sustainably sourced bamboo. Bamboo rayon production typically involves chemical processes that limit its eligibility for strict eco-labels like the Global Organic Textile Standard (GOTS). Consumers seeking certified eco-friendly bamboo fabrics should prioritize bamboo lyocell for its lower environmental impact and superior adherence to sustainable manufacturing standards.

Choosing Between Bamboo Rayon and Lyocell

Choosing between bamboo rayon and bamboo lyocell depends on factors such as environmental impact, production process, and fabric properties. Bamboo lyocell is produced using a closed-loop process that recycles water and solvents, making it more eco-friendly, while bamboo rayon involves harsher chemical treatments. Both fabrics offer softness and breathability, but lyocell tends to be stronger and more durable, making it suitable for sustainable fashion and sensitive skin.

Bamboo rayon vs Bamboo lyocell Infographic

materialdif.com

materialdif.com