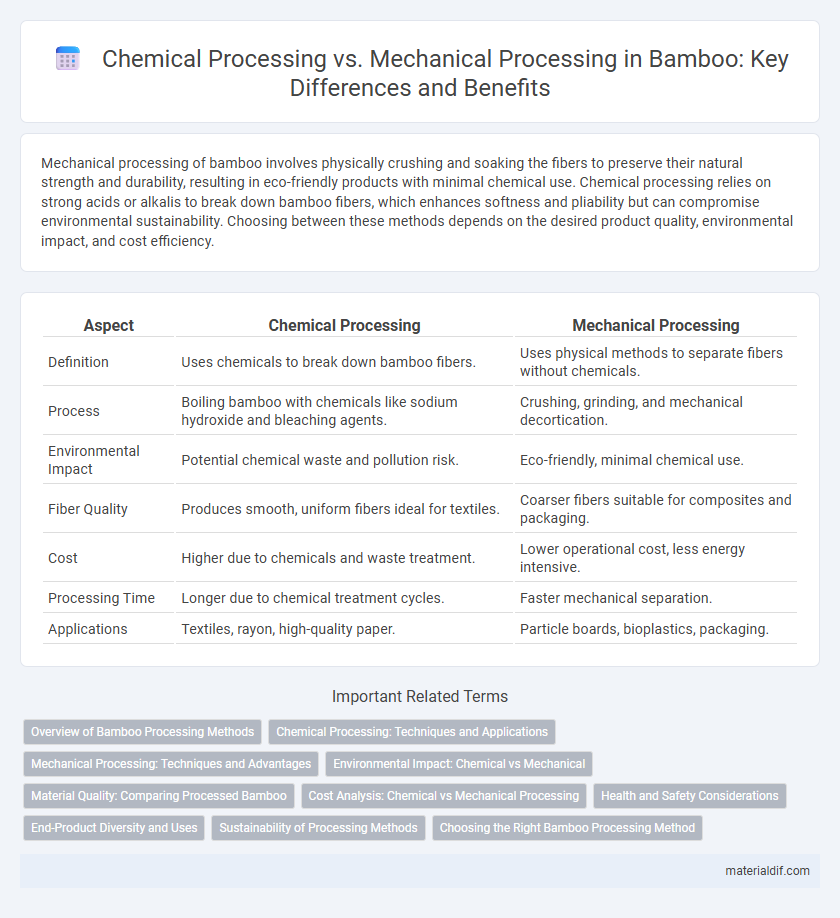

Mechanical processing of bamboo involves physically crushing and soaking the fibers to preserve their natural strength and durability, resulting in eco-friendly products with minimal chemical use. Chemical processing relies on strong acids or alkalis to break down bamboo fibers, which enhances softness and pliability but can compromise environmental sustainability. Choosing between these methods depends on the desired product quality, environmental impact, and cost efficiency.

Table of Comparison

| Aspect | Chemical Processing | Mechanical Processing |

|---|---|---|

| Definition | Uses chemicals to break down bamboo fibers. | Uses physical methods to separate fibers without chemicals. |

| Process | Boiling bamboo with chemicals like sodium hydroxide and bleaching agents. | Crushing, grinding, and mechanical decortication. |

| Environmental Impact | Potential chemical waste and pollution risk. | Eco-friendly, minimal chemical use. |

| Fiber Quality | Produces smooth, uniform fibers ideal for textiles. | Coarser fibers suitable for composites and packaging. |

| Cost | Higher due to chemicals and waste treatment. | Lower operational cost, less energy intensive. |

| Processing Time | Longer due to chemical treatment cycles. | Faster mechanical separation. |

| Applications | Textiles, rayon, high-quality paper. | Particle boards, bioplastics, packaging. |

Overview of Bamboo Processing Methods

Chemical processing of bamboo involves using solvents or treatments to break down lignin and hemicellulose, enabling the extraction of fibers suitable for textiles, composites, and paper production, often resulting in higher purity and strength. Mechanical processing relies on physical methods such as crushing, retting, and combing to separate fibers without chemical alterations, preserving the natural characteristics but typically producing coarser fibers used in construction and traditional crafts. Both methods have distinct applications depending on the desired end product, with chemical processing favored for high-performance materials and mechanical processing preferred for sustainable, eco-friendly uses.

Chemical Processing: Techniques and Applications

Chemical processing of bamboo involves methods such as pulping, bleaching, and chemical treatments to enhance durability, flexibility, and resistance to pests. Techniques include soda pulping, kraft pulping, and enzymatic treatments, which break down lignin and hemicellulose to produce fibers suitable for textiles, paper, and composite materials. Applications extend to manufacturing high-quality bamboo textiles, bio-based composites, and sustainable packaging solutions with improved mechanical properties and environmental benefits.

Mechanical Processing: Techniques and Advantages

Mechanical processing of bamboo involves techniques such as splitting, crushing, and rolling to extract fibers without using harmful chemicals. This eco-friendly method preserves the natural strength and flexibility of bamboo fibers, making them ideal for textiles and composite materials. The advantages include reduced environmental impact, improved fiber quality, and lower production costs compared to chemical processing.

Environmental Impact: Chemical vs Mechanical

Chemical processing of bamboo involves the use of solvents and strong chemicals that can produce hazardous waste and contribute to water pollution. Mechanical processing relies on physical methods like crushing and grinding, significantly reducing chemical emissions and lowering environmental toxicity. As a result, mechanical processing offers a more sustainable and eco-friendly approach compared to chemical methods in bamboo production.

Material Quality: Comparing Processed Bamboo

Chemical processing of bamboo involves using solvents and treatments that remove lignin and hemicellulose, resulting in a smoother, more uniform material with enhanced resistance to pests and moisture. Mechanical processing retains most of the natural fibers and structure, producing stronger, more durable bamboo ideal for structural applications but with greater variability in texture and strength. Evaluating material quality reveals chemical processing yields refined bamboo suitable for fine products, while mechanical processing preserves robustness needed for construction and heavy-duty uses.

Cost Analysis: Chemical vs Mechanical Processing

Chemical processing of bamboo involves the use of solvents and additives that increase production costs due to expensive raw chemicals and waste management requirements. Mechanical processing, which relies on physical methods such as crushing and grinding, tends to have lower operational expenses but may incur higher maintenance costs for machinery. Overall, mechanical processing offers a more cost-effective solution with fewer environmental liabilities compared to chemical methods.

Health and Safety Considerations

Chemical processing of bamboo involves the use of solvents and treatments that can release hazardous fumes and residues, posing respiratory and skin exposure risks to workers without proper protective equipment. Mechanical processing, such as sanding or splitting, generates dust particles that may cause respiratory issues if inhaled over long periods, necessitating adequate ventilation and dust control measures. Ensuring the use of personal protective equipment (PPE) and implementing strict industrial hygiene practices are critical to minimizing health risks in both chemical and mechanical bamboo processing methods.

End-Product Diversity and Uses

Chemical processing of bamboo involves the use of solvents and additives to break down fibers, resulting in products such as viscose rayon, bamboo charcoal, and bioplastics with diverse industrial applications. Mechanical processing retains the natural fiber structure, producing stronger, eco-friendly materials like bamboo flooring, furniture, and textiles. These methods create a wide range of end-products that cater to sectors including construction, fashion, and environmental sustainability.

Sustainability of Processing Methods

Chemical processing of bamboo often involves harsh solvents and generates toxic waste, posing significant environmental challenges and reducing overall sustainability. Mechanical processing, such as steam explosion or mechanical grinding, preserves bamboo fibers without harmful chemicals, resulting in lower energy consumption and minimal environmental impact. Prioritizing mechanical methods enhances sustainable bamboo production by reducing pollution and conserving natural resources.

Choosing the Right Bamboo Processing Method

Selecting the appropriate bamboo processing method depends on the intended application and environmental considerations. Chemical processing, involving treatments with preservatives and bleaching agents, enhances durability and resistance to pests but may introduce environmental concerns due to chemical residues. Mechanical processing, such as splitting and sanding, maintains the natural integrity of bamboo fibers, offering an eco-friendly option suitable for structural and decorative uses.

Chemical processing vs mechanical processing Infographic

materialdif.com

materialdif.com