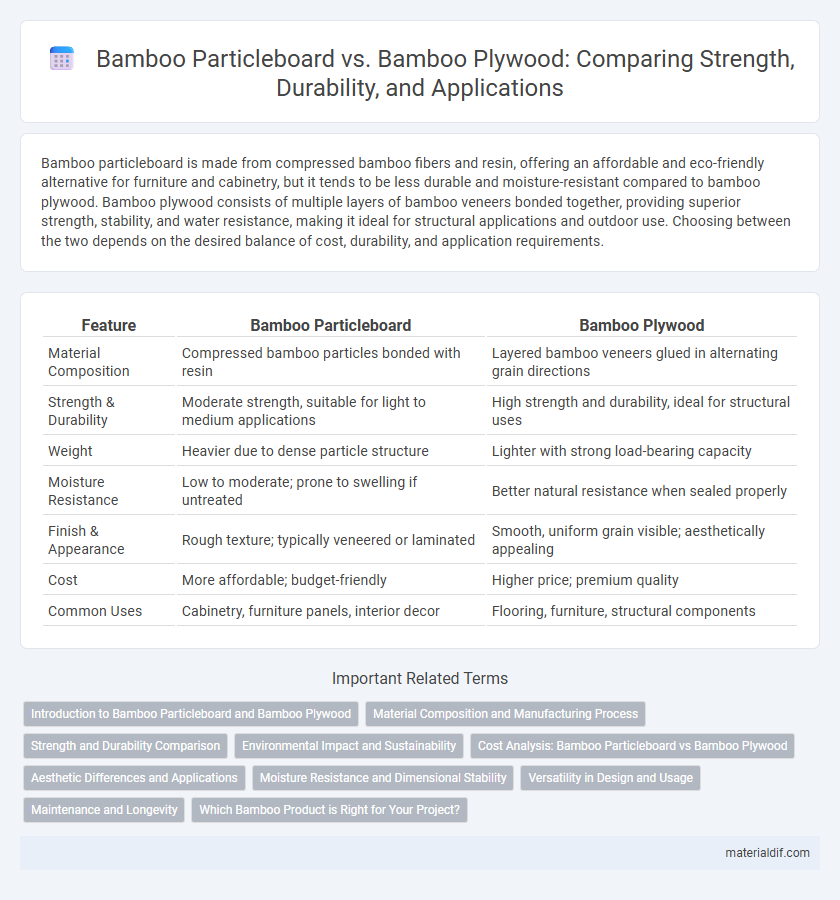

Bamboo particleboard is made from compressed bamboo fibers and resin, offering an affordable and eco-friendly alternative for furniture and cabinetry, but it tends to be less durable and moisture-resistant compared to bamboo plywood. Bamboo plywood consists of multiple layers of bamboo veneers bonded together, providing superior strength, stability, and water resistance, making it ideal for structural applications and outdoor use. Choosing between the two depends on the desired balance of cost, durability, and application requirements.

Table of Comparison

| Feature | Bamboo Particleboard | Bamboo Plywood |

|---|---|---|

| Material Composition | Compressed bamboo particles bonded with resin | Layered bamboo veneers glued in alternating grain directions |

| Strength & Durability | Moderate strength, suitable for light to medium applications | High strength and durability, ideal for structural uses |

| Weight | Heavier due to dense particle structure | Lighter with strong load-bearing capacity |

| Moisture Resistance | Low to moderate; prone to swelling if untreated | Better natural resistance when sealed properly |

| Finish & Appearance | Rough texture; typically veneered or laminated | Smooth, uniform grain visible; aesthetically appealing |

| Cost | More affordable; budget-friendly | Higher price; premium quality |

| Common Uses | Cabinetry, furniture panels, interior decor | Flooring, furniture, structural components |

Introduction to Bamboo Particleboard and Bamboo Plywood

Bamboo particleboard is engineered by compressing bamboo fibers and particles with adhesive resins, creating a dense, cost-effective panel ideal for furniture and cabinetry. Bamboo plywood consists of thin layers of bamboo veneer glued together with the grain running perpendicular to each other, offering superior strength, durability, and flexibility in construction. Both materials leverage bamboo's rapid growth and sustainability, but plywood provides enhanced structural integrity for load-bearing applications compared to particleboard.

Material Composition and Manufacturing Process

Bamboo particleboard is made by compressing small bamboo particles bonded with resin adhesive, resulting in a dense, uniform panel mainly used for furniture and interior applications. Bamboo plywood consists of thin layers of bamboo veneers glued together with alternating grain directions, enhancing strength and flexibility, suitable for structural and decorative uses. The manufacturing process of particleboard involves shredding and pressing, while plywood requires precise lamination and pressing techniques to achieve durability and dimensional stability.

Strength and Durability Comparison

Bamboo plywood offers superior strength and durability compared to bamboo particleboard due to its layered construction, which enhances load-bearing capacity and resistance to warping. Bamboo particleboard, made from compressed bamboo fibers and resin, is less dense and more prone to moisture damage and deformation over time. For structural applications requiring long-term stability, bamboo plywood is the preferred choice because of its consistent strength and resilience under stress.

Environmental Impact and Sustainability

Bamboo particleboard is made from compressed bamboo fibers combined with adhesives, often containing formaldehyde-based resins that can emit harmful VOCs, impacting indoor air quality and environmental health. Bamboo plywood, constructed by layering thin bamboo veneers with eco-friendly adhesives, offers improved durability and typically uses fewer chemical binders, reducing environmental toxicity. Both materials leverage bamboo's rapid renewability and carbon sequestration, but bamboo plywood generally presents a more sustainable option due to lower emissions and longer lifespan.

Cost Analysis: Bamboo Particleboard vs Bamboo Plywood

Bamboo particleboard typically costs less than bamboo plywood due to its lower manufacturing complexity and the use of smaller bamboo fibers combined with adhesives, making it a budget-friendly option for interior applications. Bamboo plywood involves layering thin sheets of bamboo veneers bonded under heat and pressure, resulting in higher production costs but offering superior strength and durability. Cost analysis shows that while particleboard suits cost-sensitive projects, bamboo plywood delivers better long-term value for structural uses despite its higher initial price.

Aesthetic Differences and Applications

Bamboo particleboard features a uniform, matte finish ideal for economical furniture and cabinetry, while bamboo plywood showcases natural grain patterns and varying tones suited for decorative paneling and high-end interior design. Particleboard's compressed bamboo fibers provide smooth surfaces for laminates or veneers, contrasting with plywood's layered construction that enhances strength and visual depth. Applications for particleboard typically include budget-friendly shelving and flat-pack furniture, whereas bamboo plywood excels in flooring, wall cladding, and custom cabinetry where aesthetics and durability are critical.

Moisture Resistance and Dimensional Stability

Bamboo plywood exhibits superior moisture resistance compared to bamboo particleboard due to its layered construction, which enhances water repellency and reduces swelling. Bamboo particleboard tends to absorb more moisture, leading to decreased dimensional stability and increased risk of warping or deformation. High-quality bamboo plywood is preferred in environments with fluctuating humidity for its consistent durability and shape retention.

Versatility in Design and Usage

Bamboo particleboard offers excellent versatility in design due to its uniform texture and smooth surface, making it ideal for cabinetry, furniture, and interior paneling where consistent finish is critical. Bamboo plywood provides superior strength and flexibility, allowing for curved and structural applications such as flooring, wall panels, and load-bearing furniture components. Both materials leverage bamboo's sustainability and rapid growth, but plywood's layered construction enhances durability and adaptability in complex architectural designs.

Maintenance and Longevity

Bamboo particleboard typically requires more frequent maintenance due to its lower density and susceptibility to moisture damage, limiting its longevity in high-humidity environments. Bamboo plywood offers greater durability and resistance to warping, making it a preferred choice for long-term applications where strength and stability are critical. Proper sealing and regular cleaning extend the lifespan of both materials, but bamboo plywood consistently outperforms particleboard in maintenance ease and overall durability.

Which Bamboo Product is Right for Your Project?

Bamboo particleboard offers a cost-effective and sustainable option made from compressed bamboo fibers, ideal for lightweight applications like cabinetry and furniture interiors. Bamboo plywood provides superior strength and durability with multiple layers of bamboo veneers, making it suitable for structural uses, flooring, and high-impact surfaces. Choosing between particleboard and plywood depends on your project's load requirements, budget, and desired aesthetic, with plywood preferred for robustness and particleboard for affordability.

Bamboo particleboard vs Bamboo plywood Infographic

materialdif.com

materialdif.com