Cold-pressed bamboo retains more of its natural fibers and nutrients, resulting in a stronger, more durable material ideal for eco-friendly products. Hot-pressed bamboo undergoes high heat and pressure, which makes it denser and smoother but can reduce its natural resilience. Choosing between cold-pressed and hot-pressed bamboo depends on the desired balance of strength, texture, and environmental impact.

Table of Comparison

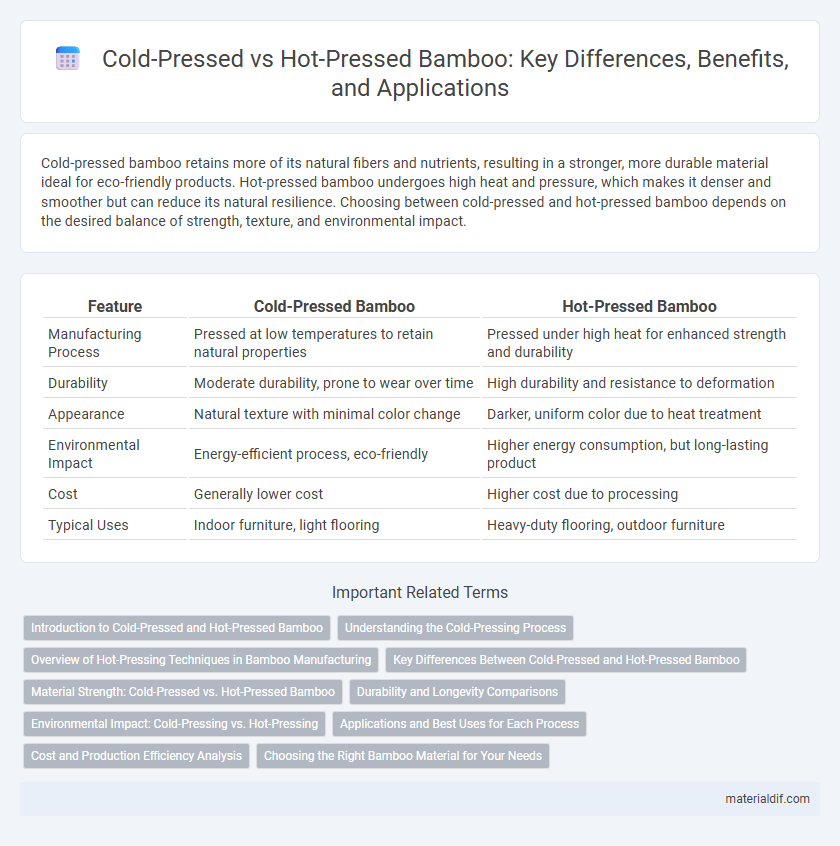

| Feature | Cold-Pressed Bamboo | Hot-Pressed Bamboo |

|---|---|---|

| Manufacturing Process | Pressed at low temperatures to retain natural properties | Pressed under high heat for enhanced strength and durability |

| Durability | Moderate durability, prone to wear over time | High durability and resistance to deformation |

| Appearance | Natural texture with minimal color change | Darker, uniform color due to heat treatment |

| Environmental Impact | Energy-efficient process, eco-friendly | Higher energy consumption, but long-lasting product |

| Cost | Generally lower cost | Higher cost due to processing |

| Typical Uses | Indoor furniture, light flooring | Heavy-duty flooring, outdoor furniture |

Introduction to Cold-Pressed and Hot-Pressed Bamboo

Cold-pressed bamboo retains higher natural oils and nutrients by applying low heat during extraction, resulting in a more durable and eco-friendly material with enhanced texture. Hot-pressed bamboo undergoes high-temperature processing that increases density and hardness, offering greater structural strength but potentially reducing moisture retention. Choosing between cold-pressed and hot-pressed bamboo depends on the desired balance between natural aesthetics and mechanical performance in applications such as flooring and furniture.

Understanding the Cold-Pressing Process

The cold-pressing process of bamboo involves applying high pressure at low temperatures to extract bamboo fibers without compromising their natural strength and flexibility, preserving essential nutrients and structural integrity. This method contrasts with hot-pressing, which uses heat and pressure that can weaken the fibers and reduce durability. Cold-pressed bamboo is preferred for eco-friendly products requiring high tensile strength and sustainable manufacturing practices.

Overview of Hot-Pressing Techniques in Bamboo Manufacturing

Hot-pressed bamboo manufacturing involves applying high heat and pressure to compressed bamboo fibers, enhancing density and durability for structural applications. This technique significantly improves moisture resistance and surface smoothness compared to cold-pressed methods, making hot-pressed bamboo ideal for flooring and furniture production. By altering bamboo's physical properties, hot pressing increases its strength and dimensional stability, which is critical for long-lasting, high-performance bamboo products.

Key Differences Between Cold-Pressed and Hot-Pressed Bamboo

Cold-pressed bamboo retains more of its natural fibers and nutrients due to the lower temperature extraction process, resulting in higher strength and better durability. Hot-pressed bamboo undergoes high heat and pressure, which enhances its density and smoothness but may reduce some natural properties. The choice between cold-pressed and hot-pressed bamboo depends on the desired balance between natural texture preservation and material uniformity.

Material Strength: Cold-Pressed vs. Hot-Pressed Bamboo

Cold-pressed bamboo maintains higher material strength due to its gentle processing, preserving fiber integrity and natural flexibility. Hot-pressed bamboo undergoes high heat and pressure, which can increase rigidity but may cause brittleness and micro-fractures within the fibers. For applications requiring durability and resilience, cold-pressed bamboo is often preferred, while hot-pressed bamboo suits uses where stiffness and form stability are prioritized.

Durability and Longevity Comparisons

Cold-pressed bamboo retains higher fiber integrity due to the lower temperatures used in processing, resulting in enhanced durability and resistance to cracking over time. Hot-pressed bamboo, subjected to elevated heat and pressure, undergoes fiber softening which can compromise long-term structural strength despite offering a smoother finish. Studies indicate that cold-pressed bamboo flooring and products consistently outperform hot-pressed variants in longevity, maintaining mechanical stability and surface resilience under heavy use.

Environmental Impact: Cold-Pressing vs. Hot-Pressing

Cold-pressed bamboo processing uses lower temperatures and less energy, resulting in reduced carbon emissions and minimal chemical waste compared to hot-pressed methods. Hot-pressing involves high heat and pressure, which increases energy consumption and can release harmful byproducts, impacting air and water quality. Choosing cold-pressed bamboo supports sustainable production by conserving resources and lowering the environmental footprint.

Applications and Best Uses for Each Process

Cold-pressed bamboo retains more natural fibers, making it ideal for applications requiring high durability and flexibility, such as eco-friendly flooring, furniture, and crafts. Hot-pressed bamboo undergoes heat and pressure treatment, producing a denser and more uniform material suited for structural uses like panels, construction, and heavy-duty flooring. Selecting cold-pressed bamboo enhances aesthetics and resilience, while hot-pressed bamboo is preferred for strength and stability in demanding environments.

Cost and Production Efficiency Analysis

Cold-pressed bamboo offers higher material integrity and lower energy consumption during production, resulting in moderate costs but improved sustainability. Hot-pressed bamboo, while more energy-intensive and costly due to elevated temperatures and pressure requirements, enables faster production cycles and higher output rates. Analyzing cost efficiency, hot-pressed bamboo suits large-scale manufacturing with tight deadlines, whereas cold-pressed bamboo is preferred for eco-friendly, lower-volume applications.

Choosing the Right Bamboo Material for Your Needs

Cold-pressed bamboo retains more of its natural strength and flexibility due to lower temperature processing, making it ideal for eco-friendly flooring and furniture with enhanced durability. Hot-pressed bamboo undergoes higher heat and pressure, resulting in a harder, denser material suitable for high-traffic areas and structural applications requiring increased resistance to wear and moisture. Selecting between cold-pressed and hot-pressed bamboo depends on the specific performance requirements and environmental conditions of your project.

Cold-pressed bamboo vs hot-pressed bamboo Infographic

materialdif.com

materialdif.com