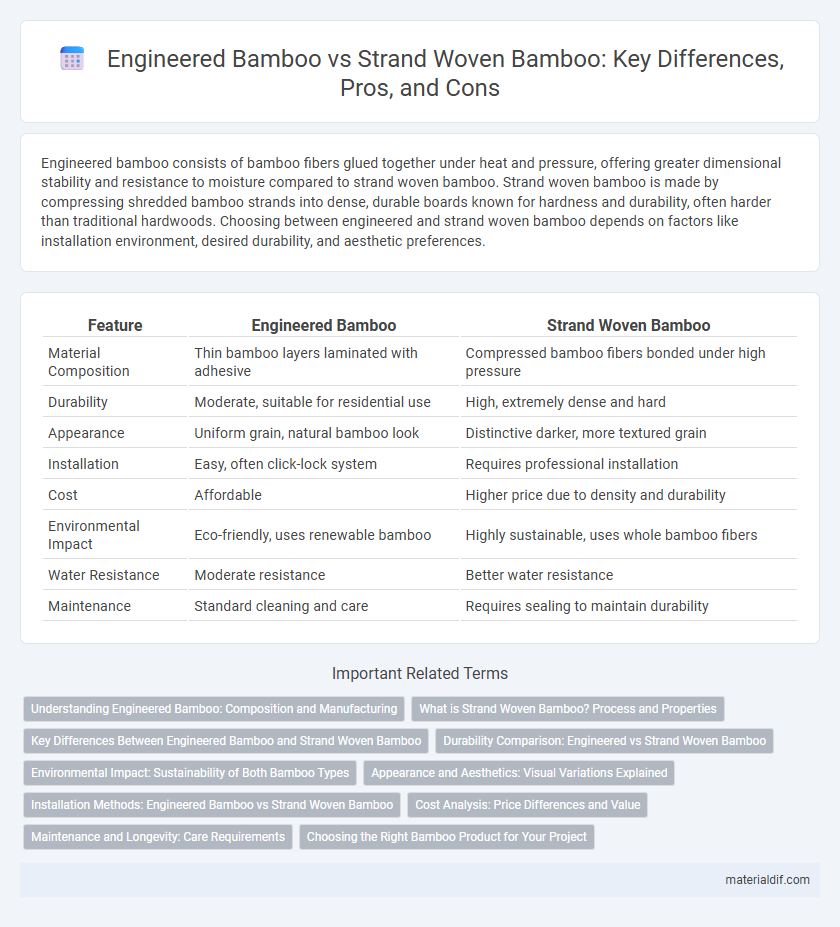

Engineered bamboo consists of bamboo fibers glued together under heat and pressure, offering greater dimensional stability and resistance to moisture compared to strand woven bamboo. Strand woven bamboo is made by compressing shredded bamboo strands into dense, durable boards known for hardness and durability, often harder than traditional hardwoods. Choosing between engineered and strand woven bamboo depends on factors like installation environment, desired durability, and aesthetic preferences.

Table of Comparison

| Feature | Engineered Bamboo | Strand Woven Bamboo |

|---|---|---|

| Material Composition | Thin bamboo layers laminated with adhesive | Compressed bamboo fibers bonded under high pressure |

| Durability | Moderate, suitable for residential use | High, extremely dense and hard |

| Appearance | Uniform grain, natural bamboo look | Distinctive darker, more textured grain |

| Installation | Easy, often click-lock system | Requires professional installation |

| Cost | Affordable | Higher price due to density and durability |

| Environmental Impact | Eco-friendly, uses renewable bamboo | Highly sustainable, uses whole bamboo fibers |

| Water Resistance | Moderate resistance | Better water resistance |

| Maintenance | Standard cleaning and care | Requires sealing to maintain durability |

Understanding Engineered Bamboo: Composition and Manufacturing

Engineered bamboo consists of multiple layers of bamboo veneers or fibers bonded with adhesives under heat and pressure, resulting in enhanced strength and stability compared to natural bamboo. Its manufacturing process involves slicing mature bamboo stalks into thin layers, which are then dried, treated for durability, and laminated to form boards suitable for flooring and furniture. This composition allows engineered bamboo to resist moisture and deformation, making it a preferred choice for sustainable, durable building materials.

What is Strand Woven Bamboo? Process and Properties

Strand woven bamboo is created by compressing shredded bamboo fibers under extreme heat and pressure, producing a dense and durable material ideal for flooring. This manufacturing process enhances its hardness, often exceeding traditional hardwoods, and increases resistance to moisture and wear. The resulting planks exhibit a uniform texture and high dimensional stability, making strand woven bamboo a preferred choice for high-traffic and moisture-prone areas compared to engineered bamboo.

Key Differences Between Engineered Bamboo and Strand Woven Bamboo

Engineered bamboo consists of multiple layers of bamboo fibers bonded with adhesives, offering enhanced stability and resistance to moisture, while strand woven bamboo is made by compressing shredded bamboo fibers into dense blocks, resulting in exceptional hardness and durability. Engineered bamboo typically has a more uniform appearance and flexibility, making it suitable for various applications including flooring and furniture, whereas strand woven bamboo is known for its superior density and wear resistance, ideal for high-traffic areas. The manufacturing process of strand woven bamboo gives it a darker, more textured look compared to the smoother finish of engineered bamboo.

Durability Comparison: Engineered vs Strand Woven Bamboo

Engineered bamboo features a layered construction that enhances stability and resistance to moisture, making it ideal for areas with varying humidity. Strand woven bamboo undergoes a compression process that creates a denser and more durable material, often surpassing traditional hardwoods in hardness and wear resistance. Durability comparison shows strand woven bamboo excels in heavy traffic environments, while engineered bamboo provides better performance against moisture-related deformation.

Environmental Impact: Sustainability of Both Bamboo Types

Engineered bamboo and strand woven bamboo both offer sustainable alternatives to traditional hardwoods, utilizing fast-growing bamboo species that sequester carbon efficiently. Engineered bamboo often involves adhesives and processing that may impact its environmental footprint, whereas strand woven bamboo uses compressed bamboo fibers with minimal resin, resulting in higher density and durability with lower emissions. Both types promote responsible forest management and reduce deforestation, but strand woven bamboo generally demonstrates a slightly better environmental profile due to its lower chemical use and extended lifespan.

Appearance and Aesthetics: Visual Variations Explained

Engineered bamboo offers a uniform appearance with consistent grain patterns and color, making it ideal for modern, sleek interiors. Strand woven bamboo showcases a denser texture with a unique, variegated look due to the compressed bamboo fibers, resulting in darker, richer tones and intricate patterns. The visual variations between engineered and strand woven bamboo cater to different aesthetic preferences, from minimalist to rustic designs.

Installation Methods: Engineered Bamboo vs Strand Woven Bamboo

Engineered bamboo floors typically feature a click-lock installation system or can be glued down, offering flexibility and ease for DIY projects. Strand woven bamboo, being denser and harder, often requires professional installation with nail-down or glue-down methods to ensure stability and durability. Both types demand acclimatization before installation to prevent expansion and contraction issues in varying humidity conditions.

Cost Analysis: Price Differences and Value

Engineered bamboo typically costs less than strand woven bamboo due to its simpler manufacturing process and lower material density. Strand woven bamboo offers higher durability and hardness, which can justify its premium price for long-term flooring investments. Cost analysis reveals that while engineered bamboo provides an affordable and sustainable option, strand woven bamboo adds greater value through enhanced strength and longevity.

Maintenance and Longevity: Care Requirements

Engineered bamboo requires minimal maintenance due to its stabilized structure, resisting moisture and temperature fluctuations that typically cause warping or cracking. Strand woven bamboo offers exceptional durability and longevity, benefiting from its dense composition that withstands heavy traffic and wear with periodic cleaning and occasional resealing. Both types can last decades with proper care, but strand woven bamboo demands slightly more maintenance to preserve its surface finish over time.

Choosing the Right Bamboo Product for Your Project

Engineered bamboo offers superior dimensional stability and uniformity, ideal for detailed architectural designs and interior applications requiring consistent performance. Strand woven bamboo, known for its exceptional hardness and durability, excels in high-traffic flooring and outdoor projects where resilience is paramount. Selecting the right bamboo product depends on project-specific needs such as load-bearing requirements, environmental exposure, and aesthetic preferences.

Engineered bamboo vs strand woven bamboo Infographic

materialdif.com

materialdif.com