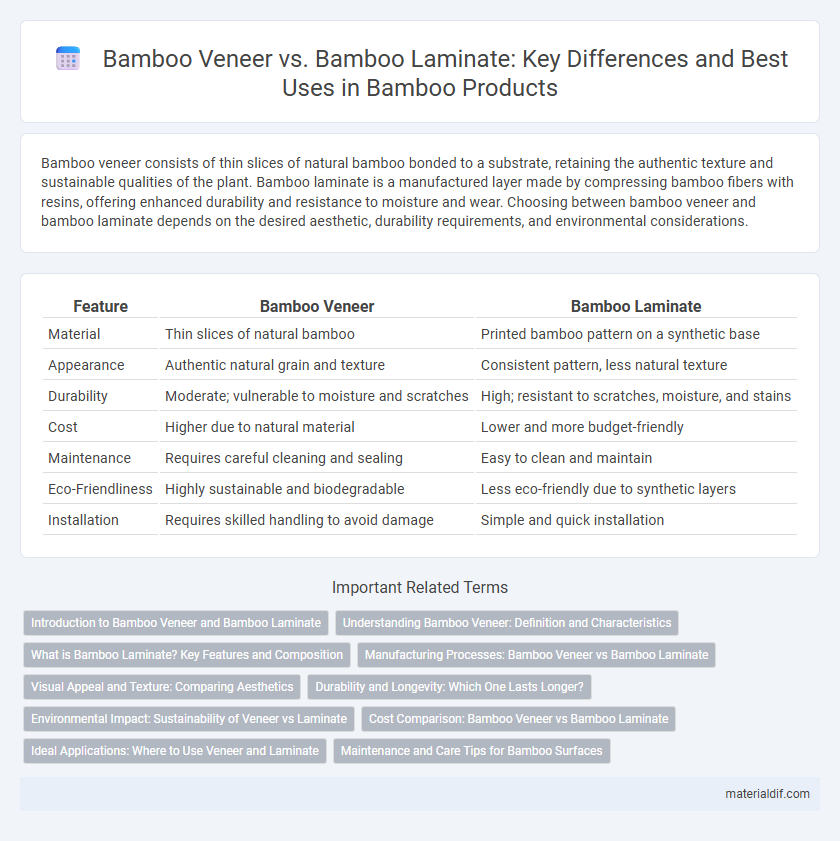

Bamboo veneer consists of thin slices of natural bamboo bonded to a substrate, retaining the authentic texture and sustainable qualities of the plant. Bamboo laminate is a manufactured layer made by compressing bamboo fibers with resins, offering enhanced durability and resistance to moisture and wear. Choosing between bamboo veneer and bamboo laminate depends on the desired aesthetic, durability requirements, and environmental considerations.

Table of Comparison

| Feature | Bamboo Veneer | Bamboo Laminate |

|---|---|---|

| Material | Thin slices of natural bamboo | Printed bamboo pattern on a synthetic base |

| Appearance | Authentic natural grain and texture | Consistent pattern, less natural texture |

| Durability | Moderate; vulnerable to moisture and scratches | High; resistant to scratches, moisture, and stains |

| Cost | Higher due to natural material | Lower and more budget-friendly |

| Maintenance | Requires careful cleaning and sealing | Easy to clean and maintain |

| Eco-Friendliness | Highly sustainable and biodegradable | Less eco-friendly due to synthetic layers |

| Installation | Requires skilled handling to avoid damage | Simple and quick installation |

Introduction to Bamboo Veneer and Bamboo Laminate

Bamboo veneer is a thin sheet of natural bamboo sliced from bamboo stalks, preserving the organic texture and grain patterns, ideal for eco-friendly and aesthetically pleasing furniture surfaces. Bamboo laminate consists of multiple layers of bamboo fibers bonded under heat and pressure to create a durable, uniform surface often used for flooring and countertops due to its enhanced strength and water resistance. Both materials leverage bamboo's rapid renewability and sustainability but differ significantly in appearance, durability, and application.

Understanding Bamboo Veneer: Definition and Characteristics

Bamboo veneer is a thin layer of natural bamboo sliced from bamboo stalks, retaining the authentic grain patterns and texture of natural bamboo. It offers superior aesthetic appeal and is often used in high-quality furniture and cabinetry due to its eco-friendly, renewable nature and biodegradability. Unlike bamboo laminate, which is a synthetic overlay, bamboo veneer provides genuine bamboo characteristics, including breathability and a natural look that ages gracefully over time.

What is Bamboo Laminate? Key Features and Composition

Bamboo laminate is a durable surface material made by bonding multiple layers of bamboo fibers or strips with resin under high pressure, creating a strong, stable sheet ideal for flooring and furniture. Its key features include resistance to moisture, scratches, and wear, as well as a consistent appearance due to the manufacturing process. Composed primarily of natural bamboo fibers combined with resins and adhesives, bamboo laminate offers enhanced durability compared to natural bamboo veneer, making it suitable for high-traffic areas and demanding environments.

Manufacturing Processes: Bamboo Veneer vs Bamboo Laminate

Bamboo veneer is created by slicing thin sheets from bamboo culms, preserving the natural grain and texture, while bamboo laminate involves layering bamboo fibers with resins under heat and pressure for enhanced durability. The veneer manufacturing process emphasizes maintaining the organic aesthetics of bamboo, ideal for decorative applications, whereas laminate production focuses on creating a robust, uniform surface resistant to scratches and moisture. Understanding these distinct manufacturing methods helps in selecting the appropriate bamboo product for specific design and functional requirements.

Visual Appeal and Texture: Comparing Aesthetics

Bamboo veneer offers a natural, rich grain pattern with a smooth, authentic texture that closely mimics solid bamboo, enhancing visual appeal in high-end furniture and cabinetry. Bamboo laminate, while available in a variety of colors and patterns, often features a printed surface with a more uniform, less textured finish that can appear less organic. The choice between veneer and laminate depends on the desired aesthetic effect, with veneer providing a warmer, more tactile experience and laminate delivering consistent visual uniformity.

Durability and Longevity: Which One Lasts Longer?

Bamboo veneer offers natural grain patterns and moderate durability but tends to be more susceptible to scratches and moisture damage compared to bamboo laminate. Bamboo laminate is constructed with a protective wear layer and resin adhesives, enhancing its resistance to abrasion, impact, and water, resulting in greater longevity. For high-traffic areas and long-term use, bamboo laminate generally outperforms bamboo veneer in durability and lifespan.

Environmental Impact: Sustainability of Veneer vs Laminate

Bamboo veneer is typically more sustainable than bamboo laminate because it uses thin slices of natural bamboo, preserving the material's organic structure and reducing the need for synthetic adhesives and resins. Laminate often involves multiple layers of bamboo fibers bonded with chemical resins, increasing environmental impact due to off-gassing and more energy-intensive production. Choosing bamboo veneer supports lower carbon emissions and greater biodegradability, aligning with eco-friendly building and design practices.

Cost Comparison: Bamboo Veneer vs Bamboo Laminate

Bamboo veneer typically costs more than bamboo laminate due to its natural material composition and more complex manufacturing process. Bamboo laminate, made from layers of paper or fabric impregnated with resin, offers a budget-friendly alternative with increased durability and easier installation. Choosing between bamboo veneer and laminate depends on balancing aesthetic preferences with cost-efficiency for flooring or furniture applications.

Ideal Applications: Where to Use Veneer and Laminate

Bamboo veneer is ideal for high-end furniture, cabinetry, and decorative wall panels where a natural, authentic appearance and fine texture are desired. Bamboo laminate is better suited for countertops, flooring, and commercial surfaces that require enhanced durability, water resistance, and ease of maintenance. Choosing between veneer and laminate depends on the application's need for aesthetic appeal versus functional resilience.

Maintenance and Care Tips for Bamboo Surfaces

Bamboo veneer requires gentle cleaning with a soft, damp cloth and periodic polishing to maintain its natural luster, avoiding excessive moisture that can cause warping. Bamboo laminate surfaces are more resistant to stains and scratches but should be cleaned with mild soap and water to prevent damage to the protective top layer. Both materials benefit from the use of coasters and furniture pads to minimize wear and preserve their durability over time.

bamboo veneer vs bamboo laminate Infographic

materialdif.com

materialdif.com