Bamboo ply offers increased strength and stability compared to solid bamboo due to its layered construction, which reduces the risk of warping and splitting. Solid bamboo provides a natural, uniform appearance but can be more susceptible to environmental changes like moisture and temperature fluctuations. Choosing between bamboo ply and solid bamboo depends on the intended application, durability requirements, and aesthetic preferences.

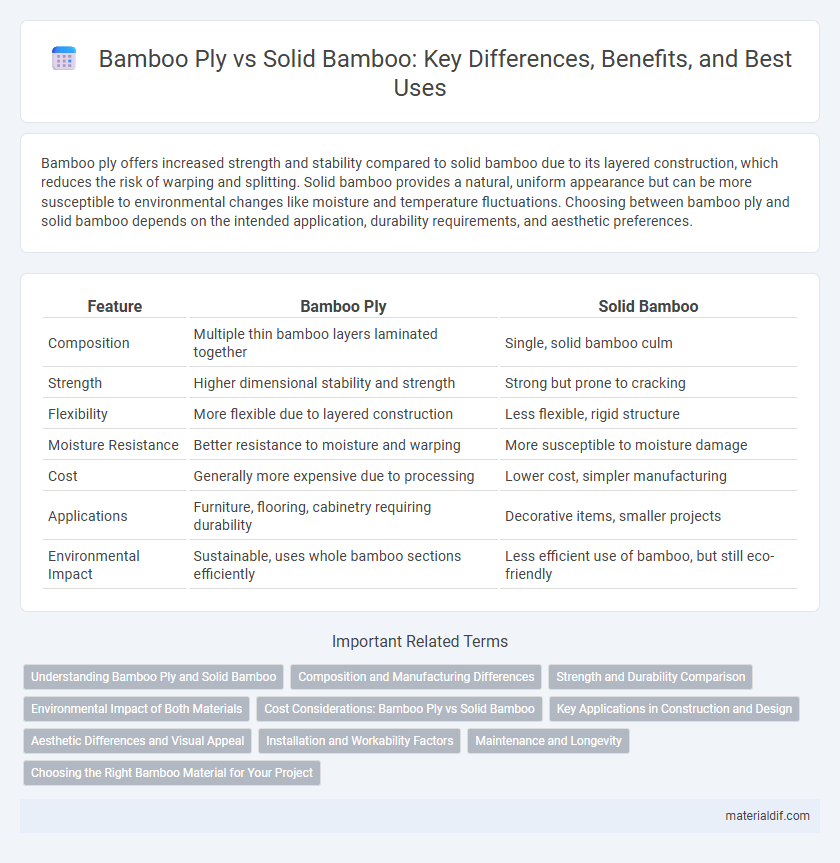

Table of Comparison

| Feature | Bamboo Ply | Solid Bamboo |

|---|---|---|

| Composition | Multiple thin bamboo layers laminated together | Single, solid bamboo culm |

| Strength | Higher dimensional stability and strength | Strong but prone to cracking |

| Flexibility | More flexible due to layered construction | Less flexible, rigid structure |

| Moisture Resistance | Better resistance to moisture and warping | More susceptible to moisture damage |

| Cost | Generally more expensive due to processing | Lower cost, simpler manufacturing |

| Applications | Furniture, flooring, cabinetry requiring durability | Decorative items, smaller projects |

| Environmental Impact | Sustainable, uses whole bamboo sections efficiently | Less efficient use of bamboo, but still eco-friendly |

Understanding Bamboo Ply and Solid Bamboo

Bamboo ply consists of multiple layers of bamboo veneers laminated together, offering enhanced strength and stability compared to solid bamboo, which is made from single, solid strips of bamboo. Solid bamboo is more prone to expansion and contraction due to moisture changes, whereas bamboo ply provides better resistance to warping and structural deformation. The engineered nature of bamboo ply makes it ideal for applications requiring durability and dimensional stability, such as flooring and furniture.

Composition and Manufacturing Differences

Bamboo plywood consists of multiple thin layers of bamboo veneer glued together, enhancing strength and stability through cross-grain construction, while solid bamboo is made from single, solid strips of bamboo that are laminated side by side. The manufacturing process of bamboo plywood involves slicing or shredding bamboo stalks into thin sheets, which are then pressed and bonded under heat and adhesive, offering uniformity and resistance to warping. Solid bamboo is typically formed by compressing and gluing strips vertically or horizontally, resulting in a denser, more natural grain appearance but often less dimensional stability compared to plywood.

Strength and Durability Comparison

Bamboo ply offers superior strength and durability due to its layered construction, which enhances resistance to warping, cracking, and splitting compared to solid bamboo. The cross-laminated layers in bamboo ply distribute stress more evenly, making it ideal for high-load applications and prolonged use. Solid bamboo, while naturally strong, tends to be more susceptible to environmental changes and physical damage over time.

Environmental Impact of Both Materials

Bamboo plywood, made by laminating thin layers of bamboo, generally has a lower environmental impact than solid bamboo due to reduced raw material usage and better resource efficiency. Solid bamboo requires harvesting whole stalks, which can lead to more significant habitat disruption and slower regrowth cycles. Manufacturing processes for plywood often produce less waste and utilize adhesives that can be optimized for eco-friendliness, further minimizing its carbon footprint compared to solid bamboo products.

Cost Considerations: Bamboo Ply vs Solid Bamboo

Bamboo ply typically offers a more cost-effective solution compared to solid bamboo due to its engineered layers that maximize material use and reduce waste. Solid bamboo, made from whole bamboo stalks, tends to be more expensive because of the higher raw material requirements and labor-intensive processing. For budget-conscious projects, bamboo ply provides durability and aesthetic appeal at a lower price point without compromising quality.

Key Applications in Construction and Design

Bamboo ply offers enhanced stability and dimensional uniformity, making it ideal for intricate architectural paneling and furniture design where precision is crucial. Solid bamboo provides superior natural strength and aesthetic appeal, commonly used in flooring, structural supports, and load-bearing applications within sustainable construction projects. Both materials contribute to eco-friendly building solutions by combining bamboo's rapid renewability with tailored mechanical properties suited for specific design requirements.

Aesthetic Differences and Visual Appeal

Bamboo ply features layered construction with alternating grain patterns, creating a distinctive, striped appearance that enhances texture and depth. Solid bamboo showcases a uniform, consistent grain that offers a smooth, natural look emphasizing the material's organic beauty. The aesthetic appeal of bamboo ply often leans toward modern, architectural designs, while solid bamboo suits minimalist and rustic styles.

Installation and Workability Factors

Bamboo plywood offers superior installation flexibility due to its layered construction, which provides enhanced stability and resistance to warping compared to solid bamboo. The uniform density of bamboo plywood allows for easier cutting, drilling, and fastening, reducing the risk of splintering and improving overall workability. Solid bamboo, while aesthetically appealing with its natural grain, can be more challenging to install due to its tendency to expand or contract with humidity changes, requiring specialized handling techniques.

Maintenance and Longevity

Bamboo plywood offers enhanced durability and is less prone to warping or cracking compared to solid bamboo, making it easier to maintain over time. Its layered construction provides better resistance to moisture and temperature changes, reducing the need for frequent repairs or refinishing. Solid bamboo may require more careful maintenance to prevent surface damage and tends to have a shorter lifespan due to its susceptibility to environmental stress.

Choosing the Right Bamboo Material for Your Project

Bamboo ply offers enhanced stability and resistance to warping compared to solid bamboo, making it ideal for larger furniture projects and flooring where durability is crucial. Solid bamboo provides a natural, aesthetic appeal with uniform grain patterns, perfect for smaller decorative items or applications emphasizing organic texture. Selecting between bamboo ply and solid bamboo depends on the project's structural requirements, desired appearance, and long-term performance expectations.

Bamboo ply vs solid bamboo Infographic

materialdif.com

materialdif.com