Cross-laminated bamboo offers superior strength and dimensional stability compared to parallel-laminated bamboo due to its layered structure, which reduces warping and enhances load distribution. Parallel-laminated bamboo, while easier to produce and often more cost-effective, tends to have less resistance to moisture and stress, limiting its use in structural applications. For sustainable construction projects requiring durable, eco-friendly materials, cross-laminated bamboo provides a practical alternative to traditional wood products.

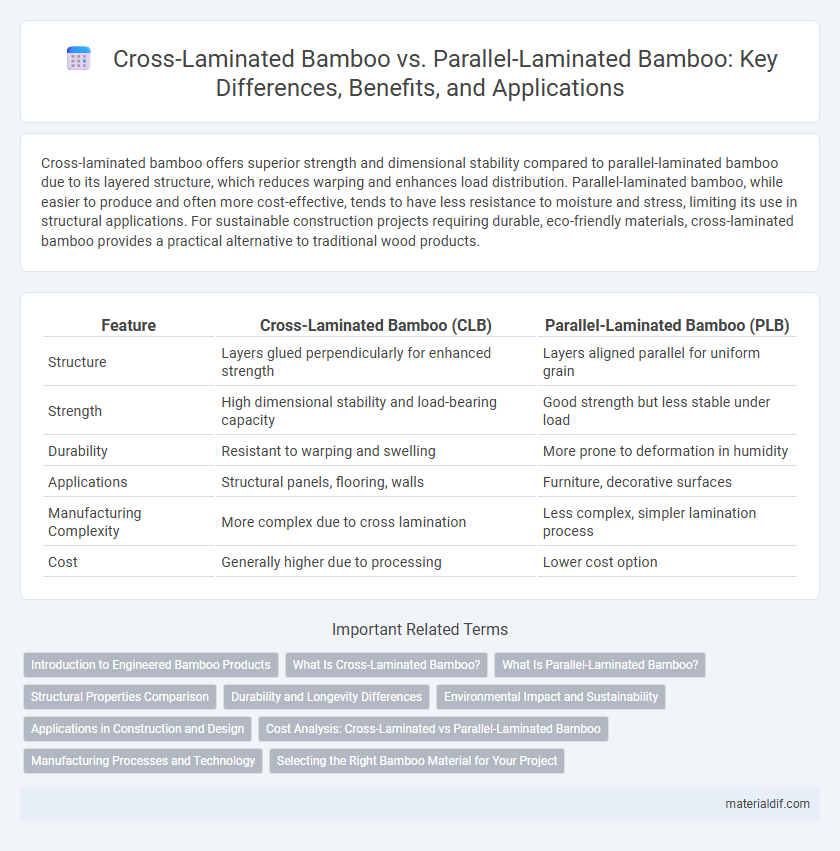

Table of Comparison

| Feature | Cross-Laminated Bamboo (CLB) | Parallel-Laminated Bamboo (PLB) |

|---|---|---|

| Structure | Layers glued perpendicularly for enhanced strength | Layers aligned parallel for uniform grain |

| Strength | High dimensional stability and load-bearing capacity | Good strength but less stable under load |

| Durability | Resistant to warping and swelling | More prone to deformation in humidity |

| Applications | Structural panels, flooring, walls | Furniture, decorative surfaces |

| Manufacturing Complexity | More complex due to cross lamination | Less complex, simpler lamination process |

| Cost | Generally higher due to processing | Lower cost option |

Introduction to Engineered Bamboo Products

Cross-laminated bamboo (CLB) features layers arranged perpendicular to each other, enhancing structural stability and strength, making it ideal for load-bearing applications. Parallel-laminated bamboo (PLB) consists of bamboo strips aligned in the same direction, offering consistent strength along the grain and a smoother surface finish suited for aesthetic purposes. Both engineered bamboo products utilize sustainable bamboo resources, providing eco-friendly alternatives to traditional timber in modern construction.

What Is Cross-Laminated Bamboo?

Cross-laminated bamboo is an engineered wood product made by layering bamboo strips perpendicular to each other, creating a strong, stable, and durable panel with enhanced structural integrity. This crosswise grain configuration reduces the natural expansion and contraction of bamboo, improving its dimensional stability compared to parallel-laminated bamboo, where layers are aligned in the same direction. Cross-laminated bamboo is widely used in construction and furniture manufacturing due to its superior load-bearing capacity and resistance to warping.

What Is Parallel-Laminated Bamboo?

Parallel-laminated bamboo consists of bamboo strips aligned in the same direction and bonded together, enhancing tensile strength and flexibility along the grain. This orientation provides superior mechanical properties for structural applications where load direction is consistent. Parallel-laminated bamboo is often preferred for flooring, beams, and panels due to its uniform appearance and high durability.

Structural Properties Comparison

Cross-laminated bamboo exhibits superior dimensional stability and increased strength due to its multi-directional grain orientation, which enhances load distribution and resistance to warping. Parallel-laminated bamboo, with fibers aligned in a single direction, offers higher tensile strength along the grain but is more susceptible to deformation under transverse loads. Structural applications benefit from cross-laminated bamboo's balanced rigidity and shear resistance, making it more suitable for complex load-bearing frameworks.

Durability and Longevity Differences

Cross-laminated bamboo offers enhanced structural durability and dimensional stability due to its perpendicular layering, which reduces warping and increases resistance to moisture and mechanical stress. Parallel-laminated bamboo, with fibers aligned in a single direction, tends to have less resistance to shear forces and is more susceptible to deformation over time. Longevity of cross-laminated bamboo products typically surpasses that of parallel-laminated variants, making it preferable for heavy-load and outdoor applications.

Environmental Impact and Sustainability

Cross-laminated bamboo offers superior environmental benefits due to its enhanced structural strength, allowing for reduced material usage and longer lifespan compared to parallel-laminated bamboo. The cross-laminated technique improves resistance to warping and moisture, increasing durability and reducing waste, which contributes to sustainable building practices. Parallel-laminated bamboo, while easier to produce, tends to have a shorter lifecycle and higher susceptibility to environmental degradation, leading to more frequent replacement and greater resource consumption.

Applications in Construction and Design

Cross-laminated bamboo offers superior structural stability and load-bearing capacity, making it ideal for flooring, wall panels, and modular construction in residential and commercial buildings. Parallel-laminated bamboo exhibits greater flexibility and aesthetic appeal, commonly used in furniture, decorative elements, and interior finishes where visual texture and design versatility are prioritized. Both types contribute to sustainable building practices by providing renewable, high-strength materials with reduced environmental impact.

Cost Analysis: Cross-Laminated vs Parallel-Laminated Bamboo

Cross-laminated bamboo typically involves higher manufacturing costs due to its multilayer construction, which enhances structural strength and dimensional stability. Parallel-laminated bamboo is generally less expensive, featuring simpler lamination with fibers aligned uniformly, resulting in lower production complexity and material waste. Cost analysis reveals that while cross-laminated bamboo may demand greater initial investment, its durability and performance benefits can lead to long-term savings in construction projects.

Manufacturing Processes and Technology

Cross-laminated bamboo involves layering bamboo strips perpendicularly, which enhances structural strength through interlocking grains, using advanced pressing and adhesive technologies for uniform bonding. Parallel-laminated bamboo consists of bamboo strips aligned in the same direction, relying on simpler lamination techniques and less complex machinery, resulting in a more flexible but less rigid panel. Manufacturing cross-laminated bamboo typically requires precision equipment and controlled curing processes to ensure high dimensional stability and load-bearing capacity.

Selecting the Right Bamboo Material for Your Project

Cross-laminated bamboo offers superior strength and dimensional stability by alternating grain directions, making it ideal for structural applications requiring load-bearing capacity. Parallel-laminated bamboo, with grain fibers aligned uniformly, provides a smoother finish and is better suited for aesthetic projects and indoor furniture where visual appeal is prioritized. Selecting the right bamboo material depends on balancing mechanical performance needs with design goals, ensuring optimal durability and appearance for your construction or craft project.

Cross-laminated bamboo vs parallel-laminated bamboo Infographic

materialdif.com

materialdif.com