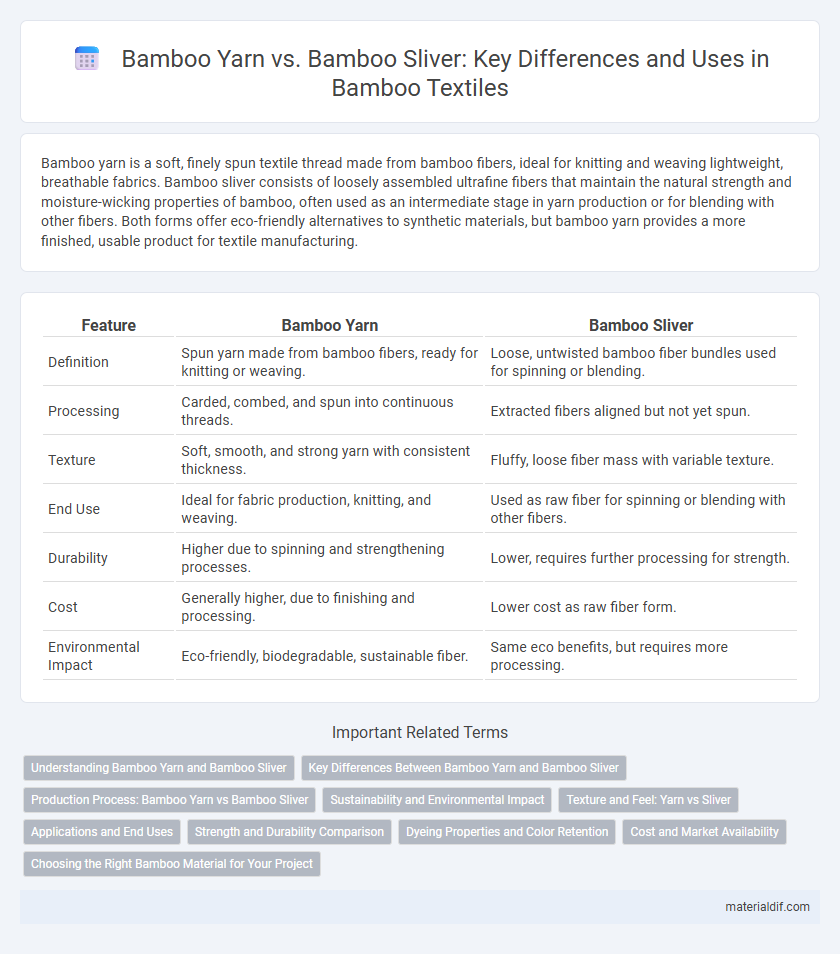

Bamboo yarn is a soft, finely spun textile thread made from bamboo fibers, ideal for knitting and weaving lightweight, breathable fabrics. Bamboo sliver consists of loosely assembled ultrafine fibers that maintain the natural strength and moisture-wicking properties of bamboo, often used as an intermediate stage in yarn production or for blending with other fibers. Both forms offer eco-friendly alternatives to synthetic materials, but bamboo yarn provides a more finished, usable product for textile manufacturing.

Table of Comparison

| Feature | Bamboo Yarn | Bamboo Sliver |

|---|---|---|

| Definition | Spun yarn made from bamboo fibers, ready for knitting or weaving. | Loose, untwisted bamboo fiber bundles used for spinning or blending. |

| Processing | Carded, combed, and spun into continuous threads. | Extracted fibers aligned but not yet spun. |

| Texture | Soft, smooth, and strong yarn with consistent thickness. | Fluffy, loose fiber mass with variable texture. |

| End Use | Ideal for fabric production, knitting, and weaving. | Used as raw fiber for spinning or blending with other fibers. |

| Durability | Higher due to spinning and strengthening processes. | Lower, requires further processing for strength. |

| Cost | Generally higher, due to finishing and processing. | Lower cost as raw fiber form. |

| Environmental Impact | Eco-friendly, biodegradable, sustainable fiber. | Same eco benefits, but requires more processing. |

Understanding Bamboo Yarn and Bamboo Sliver

Bamboo yarn is produced by spinning bamboo fibers into fine threads, resulting in a smooth, soft texture ideal for textiles and clothing. Bamboo sliver, on the other hand, refers to a loose, untwisted bundle of aligned bamboo fibers that serves as the intermediate raw material in the yarn production process. Understanding the distinction between bamboo yarn and bamboo sliver is essential for optimizing textile manufacturing and ensuring the desired quality and durability of bamboo-based fabrics.

Key Differences Between Bamboo Yarn and Bamboo Sliver

Bamboo yarn is a spun fiber used primarily in textile manufacturing, known for its softness and breathability, while bamboo sliver consists of untwisted, continuous strands aligned for processes like spinning or weaving. The key differences lie in processing stages; bamboo sliver is an intermediate product formed after fiber extraction, whereas bamboo yarn results from twisting slivers into threads suitable for knitting or weaving. Bamboo yarn offers greater versatility in fabric production, while bamboo sliver mainly serves as a preparatory material for subsequent textile creation.

Production Process: Bamboo Yarn vs Bamboo Sliver

Bamboo yarn is produced by spinning bamboo fibers into fine threads, involving processes such as carding, combing, and drawing to enhance fiber alignment and strength. Bamboo sliver, on the other hand, is a loosely assembled bundle of bamboo fibers prepared through retting and mechanical extraction but not yet spun, maintaining a raw, fibrous form ideal for further processing. The key distinction lies in bamboo yarn undergoing extensive mechanical refinement and twisting, while bamboo sliver retains a more natural, unspun fiber state.

Sustainability and Environmental Impact

Bamboo yarn and bamboo sliver differ significantly in their sustainability and environmental impact, with bamboo yarn often involving chemical-intensive processing that can reduce its eco-friendliness. Bamboo sliver, produced through mechanical processes without harsh chemicals, retains more of the bamboo's natural strength and biodegradability, making it a more sustainable choice for textile production. The reduced chemical usage in bamboo sliver manufacturing minimizes water pollution and energy consumption, enhancing its overall environmental benefits compared to conventional bamboo yarn.

Texture and Feel: Yarn vs Sliver

Bamboo yarn is spun and tightly twisted, resulting in a smooth, soft texture that feels gentle and luxurious against the skin. Bamboo sliver, being a continuous bundle of fibers, has a fluffier, more airy texture that is less processed and feels more natural and breathable. The tactile difference lies in the yarn's refined finish versus the sliver's raw, silky softness, impacting the end use in textiles and comfort.

Applications and End Uses

Bamboo yarn, known for its softness and breathability, is widely used in apparel such as t-shirts, underwear, and baby clothing due to its moisture-wicking and antibacterial properties. Bamboo sliver, a semi-processed form of bamboo fiber, is primarily utilized in textile manufacturing to produce yarns or blended fibers for upholstery, home textiles, and industrial applications. The choice between bamboo yarn and bamboo sliver affects product quality and end-use performance, with yarn offering finished textile solutions and sliver serving as an intermediate material for further processing.

Strength and Durability Comparison

Bamboo yarn exhibits superior strength and durability compared to bamboo sliver due to its enhanced fiber processing and twisting techniques that increase tensile strength and resistance to wear. Bamboo slivers, being less processed, are more prone to fraying and weaker tensile properties, making them less suitable for high-stress textile applications. The transformation from bamboo sliver to yarn significantly improves fabric longevity, strength, and resilience in finished textile products.

Dyeing Properties and Color Retention

Bamboo yarn exhibits superior dye absorption and color retention compared to bamboo sliver due to its more compact and processed fiber structure, allowing for uniform dye penetration and vibrant, long-lasting hues. Bamboo sliver, being less refined, tends to have a coarser texture and uneven surface, resulting in less consistent dye uptake and quicker fading over time. The enhanced dye affinity of bamboo yarn makes it ideal for high-quality textiles requiring durable and vivid coloration.

Cost and Market Availability

Bamboo yarn typically costs more than bamboo sliver due to the additional processing required for spinning into fine threads, making it a premium choice in textile manufacturing. Bamboo sliver, a loosely twisted fiber bundle, is more readily available and affordable, favored by businesses focused on bulk production or blending with other fibers. Market availability of bamboo yarn is concentrated among specialized textile suppliers, whereas bamboo sliver enjoys wider distribution across raw material markets and fiber wholesalers.

Choosing the Right Bamboo Material for Your Project

Bamboo yarn offers a finer, smoother texture ideal for lightweight garments and detailed knitting or crochet projects, while bamboo sliver provides a thicker, more textured fiber suitable for spinning and felting applications. Choosing between bamboo yarn and sliver depends on the desired finish and project requirements, with yarn delivering ready-to-use strands and sliver offering versatility in custom spinning. Understanding the differences in fiber preparation helps optimize the softness, strength, and sustainability benefits inherent in bamboo materials.

Bamboo yarn vs bamboo sliver Infographic

materialdif.com

materialdif.com