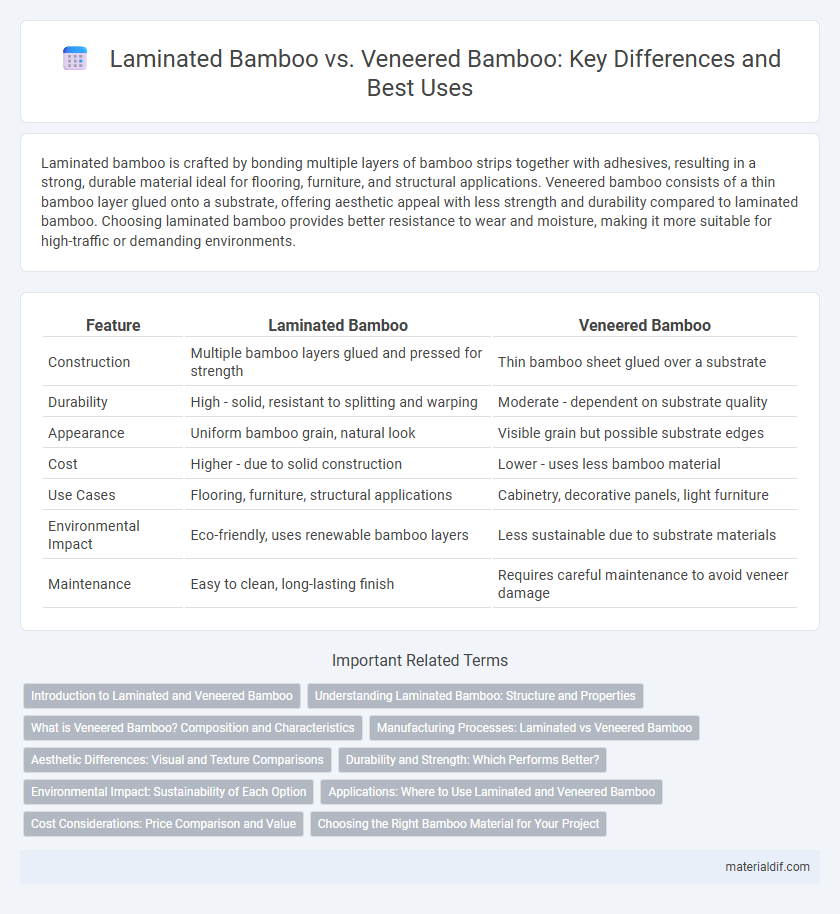

Laminated bamboo is crafted by bonding multiple layers of bamboo strips together with adhesives, resulting in a strong, durable material ideal for flooring, furniture, and structural applications. Veneered bamboo consists of a thin bamboo layer glued onto a substrate, offering aesthetic appeal with less strength and durability compared to laminated bamboo. Choosing laminated bamboo provides better resistance to wear and moisture, making it more suitable for high-traffic or demanding environments.

Table of Comparison

| Feature | Laminated Bamboo | Veneered Bamboo |

|---|---|---|

| Construction | Multiple bamboo layers glued and pressed for strength | Thin bamboo sheet glued over a substrate |

| Durability | High - solid, resistant to splitting and warping | Moderate - dependent on substrate quality |

| Appearance | Uniform bamboo grain, natural look | Visible grain but possible substrate edges |

| Cost | Higher - due to solid construction | Lower - uses less bamboo material |

| Use Cases | Flooring, furniture, structural applications | Cabinetry, decorative panels, light furniture |

| Environmental Impact | Eco-friendly, uses renewable bamboo layers | Less sustainable due to substrate materials |

| Maintenance | Easy to clean, long-lasting finish | Requires careful maintenance to avoid veneer damage |

Introduction to Laminated and Veneered Bamboo

Laminated bamboo consists of multiple bamboo strips bonded together under heat and pressure, enhancing strength and durability for construction and furniture applications. Veneered bamboo features a thin layer of bamboo glued onto a substrate, offering an aesthetic bamboo appearance with added flexibility in design. Both materials leverage bamboo's natural sustainability while serving different functional and decorative purposes.

Understanding Laminated Bamboo: Structure and Properties

Laminated bamboo is constructed by bonding multiple thin strips of bamboo with strong adhesives, creating a dense and stable material known for its superior strength and durability compared to veneered bamboo, which consists of a thin bamboo layer glued onto a substrate. The cross-grain structure of laminated bamboo enhances its resistance to warping, splitting, and moisture damage, making it ideal for flooring, furniture, and structural applications. Its uniform density and hardness offer improved load-bearing capacity and longevity, distinguishing it as a premium sustainable building material.

What is Veneered Bamboo? Composition and Characteristics

Veneered bamboo consists of thin layers of bamboo sheets glued onto a substrate, offering a decorative surface with natural bamboo aesthetics. This composition provides flexibility in design while maintaining lightweight properties but may have lower durability compared to laminated bamboo. Characterized by its smooth texture and varied grain patterns, veneered bamboo is commonly used for furniture and interior surfaces where appearance is prioritized over structural strength.

Manufacturing Processes: Laminated vs Veneered Bamboo

Laminated bamboo is produced by slicing bamboo stalks into thin strips, which are then boiled, dried, and bonded together with strong adhesives under heat and pressure to create dense, durable panels. Veneered bamboo involves bonding a thin layer of bamboo veneer onto a substrate made from other materials such as plywood or MDF, offering a more cost-effective but less structurally robust option. The manufacturing process of laminated bamboo results in higher strength and uniformity, making it ideal for flooring and furniture, while veneered bamboo is mainly used for decorative surfaces.

Aesthetic Differences: Visual and Texture Comparisons

Laminated bamboo features a consistent grain pattern with smooth, uniform textures resulting from compressed bamboo strips, creating a sleek, modern aesthetic ideal for contemporary interiors. Veneered bamboo displays more natural variation in color and grain, showcasing authentic bamboo nodes and fibers that offer a textured, organic look suited for rustic or traditional designs. The laminated option provides a polished finish with subtle sheen, while veneered bamboo emphasizes tactile richness and visual depth through its inherent natural irregularities.

Durability and Strength: Which Performs Better?

Laminated bamboo is crafted by compressing multiple layers of bamboo strips with adhesive, resulting in superior strength and durability compared to veneered bamboo, which consists of a thin bamboo layer glued onto a substrate. The dense, multi-layered construction of laminated bamboo enhances resistance to impact, moisture, and warping, making it ideal for high-traffic flooring and structural applications. In contrast, veneered bamboo, while visually appealing and cost-effective, tends to be less durable due to its thinner bamboo surface and reliance on the underlying material's stability.

Environmental Impact: Sustainability of Each Option

Laminated bamboo is generally more sustainable as it uses whole bamboo strips compressed with eco-friendly adhesives, maximizing material efficiency and reducing waste. Veneered bamboo involves thin layers of bamboo glued onto core materials like plywood, which may include less renewable or synthetic components, increasing its environmental footprint. Choosing laminated bamboo supports lower emissions and resource conservation due to its solid composition and minimal use of non-bamboo materials.

Applications: Where to Use Laminated and Veneered Bamboo

Laminated bamboo excels in structural applications such as flooring, furniture, and cabinetry due to its strength and durability, making it ideal for high-traffic and load-bearing environments. Veneered bamboo is commonly used in decorative panels, wall coverings, and light furniture where aesthetic appeal and surface finish are prioritized over structural strength. Both materials offer sustainable alternatives, with laminated bamboo suited for functional uses and veneered bamboo enhancing interior design elements.

Cost Considerations: Price Comparison and Value

Laminated bamboo typically costs more upfront than veneered bamboo due to its solid construction and durability, offering greater long-term value in flooring and furniture applications. Veneered bamboo is budget-friendly, as it uses a thin bamboo layer over a substrate, making it suitable for decorative purposes but less resistant to wear. Cost-conscious buyers should weigh initial price savings against laminated bamboo's higher resilience and lifespan to optimize investment.

Choosing the Right Bamboo Material for Your Project

Laminated bamboo offers superior strength and durability due to its multi-layer bonding process, making it ideal for flooring and structural applications requiring high resilience. Veneered bamboo features a thin decorative bamboo layer bonded to a substrate, providing aesthetic appeal but less durability compared to laminated options. Selecting laminated bamboo ensures long-term performance for high-traffic areas, while veneered bamboo suits projects emphasizing design and cost-effectiveness.

laminated bamboo vs veneered bamboo Infographic

materialdif.com

materialdif.com