Bamboo veneer consists of thin slices of bamboo glued onto a core material, offering a lightweight and cost-effective option with a smooth, decorative surface ideal for furniture and cabinetry. Bamboo plywood, made by layering and compressing multiple bamboo sheets, provides enhanced strength, durability, and stability, making it suitable for structural uses and heavy-duty applications. While bamboo veneer emphasizes aesthetics, bamboo plywood delivers superior performance in load-bearing and moisture-resistant environments.

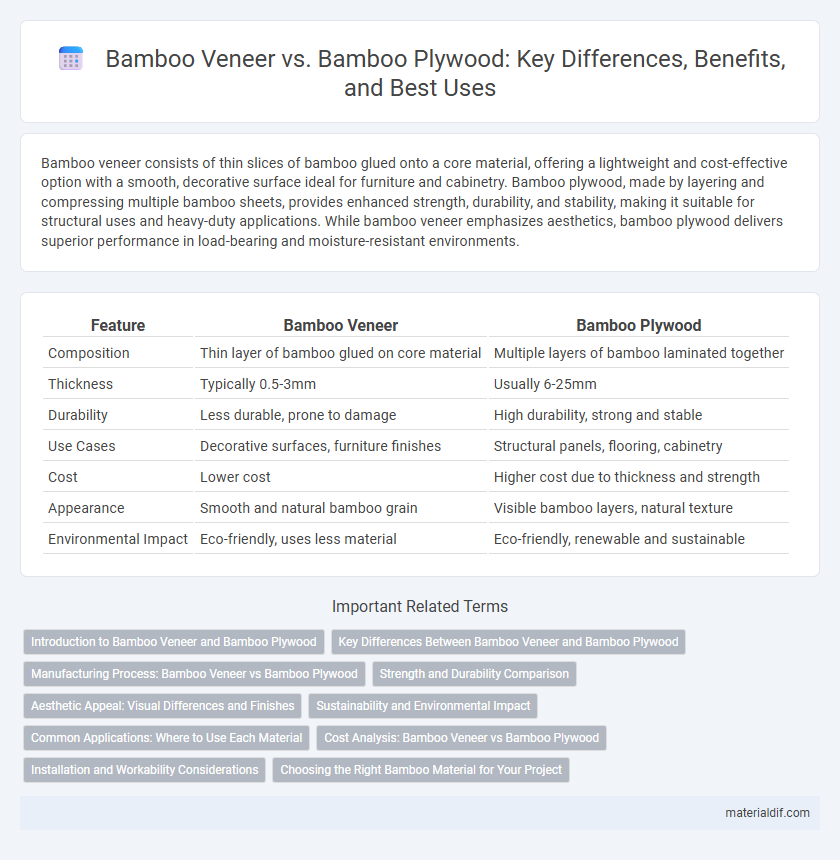

Table of Comparison

| Feature | Bamboo Veneer | Bamboo Plywood |

|---|---|---|

| Composition | Thin layer of bamboo glued on core material | Multiple layers of bamboo laminated together |

| Thickness | Typically 0.5-3mm | Usually 6-25mm |

| Durability | Less durable, prone to damage | High durability, strong and stable |

| Use Cases | Decorative surfaces, furniture finishes | Structural panels, flooring, cabinetry |

| Cost | Lower cost | Higher cost due to thickness and strength |

| Appearance | Smooth and natural bamboo grain | Visible bamboo layers, natural texture |

| Environmental Impact | Eco-friendly, uses less material | Eco-friendly, renewable and sustainable |

Introduction to Bamboo Veneer and Bamboo Plywood

Bamboo veneer consists of thin sheets sliced from bamboo culms, offering a lightweight, flexible surface ideal for decorative applications and fine woodworking. Bamboo plywood is manufactured by laminating multiple layers of bamboo veneers together with adhesive, creating a stronger, thicker, and more durable panel suited for structural and furniture projects. Both materials showcase bamboo's sustainability and aesthetic appeal but differ significantly in strength, thickness, and versatility based on their construction processes.

Key Differences Between Bamboo Veneer and Bamboo Plywood

Bamboo veneer consists of thin slices of bamboo glued onto a substrate, offering a decorative surface with less structural strength than bamboo plywood. Bamboo plywood is made by layering and compressing multiple bamboo veneers crosswise, resulting in a more durable and stable material suitable for load-bearing applications. The key differences lie in their composition, strength, cost, and typical uses, with veneer favored for aesthetic finishes and plywood preferred for furniture and construction.

Manufacturing Process: Bamboo Veneer vs Bamboo Plywood

Bamboo veneer is produced by slicing thin layers from bamboo culms, preserving the natural grain and offering a smooth, decorative surface ideal for furniture or paneling. Bamboo plywood is manufactured by laminating multiple thin layers of bamboo veneer together with adhesive under heat and pressure, creating a stronger, more durable composite material suitable for structural applications. The key manufacturing difference lies in veneer involving a single sliced layer, whereas plywood combines several layers for enhanced strength and stability.

Strength and Durability Comparison

Bamboo plywood offers superior strength and durability compared to bamboo veneer due to its multi-layered construction, which enhances resistance to warping and structural stress. Bamboo veneer, while aesthetically pleasing with natural grain patterns, lacks the reinforced stability found in plywood and is more prone to surface damage and splitting. For applications requiring long-term resilience, bamboo plywood is a more reliable choice, especially in furniture and flooring where load-bearing capacity and moisture resistance are critical.

Aesthetic Appeal: Visual Differences and Finishes

Bamboo veneer offers a thin, smooth layer that highlights the natural grain patterns with a refined and consistent finish, ideal for decorative surfaces where subtlety is key. Bamboo plywood consists of multiple layers of laminated bamboo strips, providing a thicker, more robust panel with visible edge layering that adds textural depth to furniture and cabinetry. The finish on bamboo veneer tends to be more polished and uniform, while bamboo plywood retains a tactile, organic look that enhances rustic or modern designs.

Sustainability and Environmental Impact

Bamboo veneer and bamboo plywood both offer sustainable alternatives to traditional wood, but bamboo veneer typically requires less processing, resulting in a lower carbon footprint. Bamboo plywood, composed of multiple bamboo layers glued together, provides enhanced durability and strength, making it ideal for long-lasting applications while still maintaining bamboo's rapid renewability. Both materials contribute to environmental conservation by utilizing bamboo's fast growth rate and minimal need for pesticides or fertilizers, reducing deforestation and habitat loss.

Common Applications: Where to Use Each Material

Bamboo veneer is commonly used for decorative surfaces such as furniture facades, wall panels, and cabinetry due to its thin, flexible layers that provide a smooth, aesthetic finish. Bamboo plywood, being thicker and more structurally stable, is ideal for load-bearing applications like flooring, shelving, and structural components in furniture construction. Choosing between bamboo veneer and plywood depends on whether the project prioritizes visual appeal or strength and durability.

Cost Analysis: Bamboo Veneer vs Bamboo Plywood

Bamboo veneer generally costs less than bamboo plywood due to its thinner layers and reduced material usage, making it a budget-friendly option for surface applications. Bamboo plywood, composed of multiple laminated layers, offers superior strength and durability but comes at a higher price point because of the manufacturing complexity. Cost differences also reflect variations in thickness, structural integrity, and intended use, with veneer favoring aesthetics and plywood prioritizing functional performance.

Installation and Workability Considerations

Bamboo veneer offers greater flexibility and ease of installation due to its thin, lightweight nature, making it ideal for decorative surfaces and intricate designs. Bamboo plywood, composed of multiple layers laminated together, provides superior strength and stability, which facilitates handling during structural applications but requires precise cutting and fastening techniques. When selecting materials, consider bamboo veneer for applications prioritizing aesthetics and ease of manipulation, while bamboo plywood suits projects demanding durability and load-bearing capacity.

Choosing the Right Bamboo Material for Your Project

Bamboo veneer offers a thin, flexible surface layer ideal for decorative applications and lightweight projects, while bamboo plywood consists of multiple laminated layers providing superior strength and durability for structural use. Selecting bamboo veneer suits furniture facing or cabinetry requiring an attractive finish, whereas bamboo plywood excels in flooring, cabinetry, and load-bearing constructions due to its stability and resistance to splitting. Understanding the specific requirements of your project, such as load capacity and aesthetic preference, ensures the right bamboo material enhances both functionality and design.

Bamboo veneer vs bamboo plywood Infographic

materialdif.com

materialdif.com