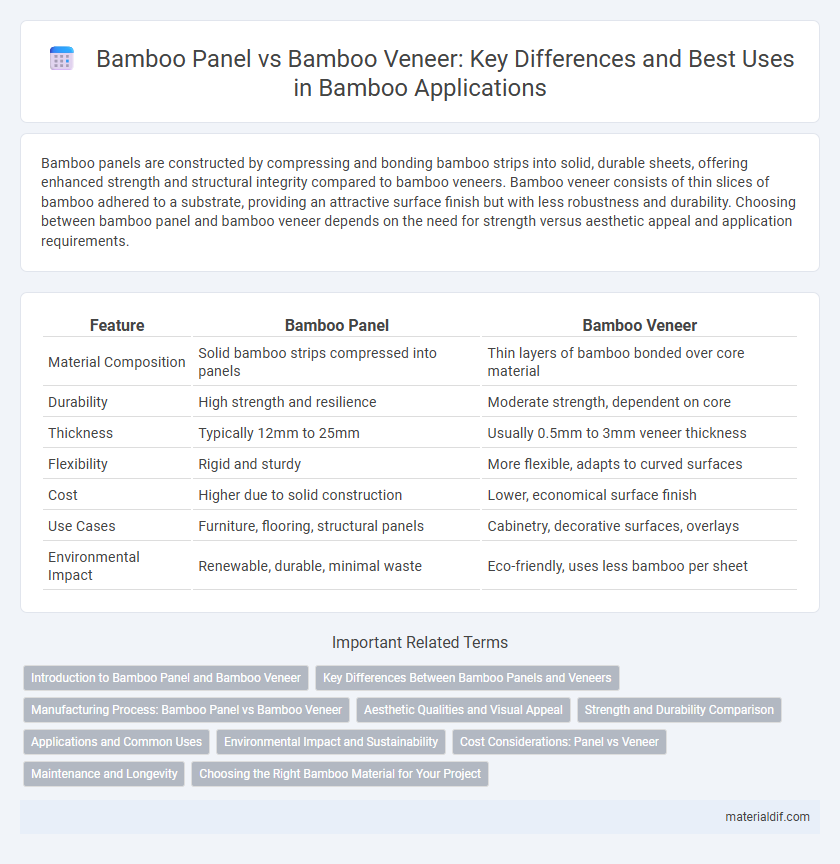

Bamboo panels are constructed by compressing and bonding bamboo strips into solid, durable sheets, offering enhanced strength and structural integrity compared to bamboo veneers. Bamboo veneer consists of thin slices of bamboo adhered to a substrate, providing an attractive surface finish but with less robustness and durability. Choosing between bamboo panel and bamboo veneer depends on the need for strength versus aesthetic appeal and application requirements.

Table of Comparison

| Feature | Bamboo Panel | Bamboo Veneer |

|---|---|---|

| Material Composition | Solid bamboo strips compressed into panels | Thin layers of bamboo bonded over core material |

| Durability | High strength and resilience | Moderate strength, dependent on core |

| Thickness | Typically 12mm to 25mm | Usually 0.5mm to 3mm veneer thickness |

| Flexibility | Rigid and sturdy | More flexible, adapts to curved surfaces |

| Cost | Higher due to solid construction | Lower, economical surface finish |

| Use Cases | Furniture, flooring, structural panels | Cabinetry, decorative surfaces, overlays |

| Environmental Impact | Renewable, durable, minimal waste | Eco-friendly, uses less bamboo per sheet |

Introduction to Bamboo Panel and Bamboo Veneer

Bamboo panels are engineered sheets made by compressing and bonding strips or fibers of bamboo to create strong, durable flat surfaces for furniture and construction. Bamboo veneer consists of thinly sliced bamboo layers glued onto substrates, providing an aesthetic bamboo surface while using less material. Both offer sustainable alternatives to traditional wood, but panels deliver structural integrity, whereas veneers emphasize decorative finishes.

Key Differences Between Bamboo Panels and Veneers

Bamboo panels are constructed from compressed bamboo fibers or strips, providing uniform thickness and durability, while bamboo veneers are thin slices of bamboo adhered to surfaces for aesthetic appeal. Panels offer structural strength suitable for furniture and flooring, whereas veneers primarily serve decorative purposes without significant load-bearing capacity. The manufacturing processes differ, with panels requiring lamination and pressing, and veneers involving slicing and bonding techniques.

Manufacturing Process: Bamboo Panel vs Bamboo Veneer

Bamboo panels are manufactured by compressing shredded or flattened bamboo strips into dense, solid boards using high pressure and adhesives, resulting in a sturdy, uniform material ideal for furniture and flooring. Bamboo veneer production involves slicing thin, flexible layers directly from bamboo culms, which are then bonded onto substrates to create a decorative surface with the natural bamboo grain. The panel manufacturing process emphasizes structural integrity and thickness, while veneer production focuses on surface aesthetics and lightweight applications.

Aesthetic Qualities and Visual Appeal

Bamboo panels offer a uniform, consistent aesthetic with a modern, sleek surface that showcases the natural grain patterns in a structured layout, enhancing contemporary interior designs. Bamboo veneer provides a more delicate and intricate visual appeal, emphasizing the rich textures and variations of the bamboo fibers for a warm, organic look. The choice between bamboo panel and veneer significantly influences the depth and character of a space, balancing durability with decorative elegance.

Strength and Durability Comparison

Bamboo panels offer greater strength and durability compared to bamboo veneer due to their solid, layered construction which provides enhanced resistance to impact and warping. Bamboo veneer, consisting of thinly sliced bamboo sheets adhered to a substrate, is more prone to damage and wear over time, especially in high-traffic or moisture-prone environments. The density and thickness of bamboo panels make them a superior choice for structural applications requiring long-lasting performance.

Applications and Common Uses

Bamboo panels are widely used for flooring, cabinetry, and furniture due to their durability and structural strength, making them ideal for load-bearing applications. Bamboo veneer, being thinner and more flexible, is commonly applied as surface finishing in interior design, wall coverings, and decorative elements to provide an aesthetic bamboo appearance. Both materials offer sustainable options but cater differently to construction versus decorative purposes.

Environmental Impact and Sustainability

Bamboo panels are engineered from compressed strips of bamboo, offering durability and long-lasting use with minimal waste, while bamboo veneer involves thin layers peeled from bamboo culms that consume fewer raw materials but may require adhesive treatments. The production of bamboo panels typically uses low-VOC adhesives and sustainable harvesting practices, reducing environmental impact by promoting rapid regrowth and carbon sequestration. Bamboo veneers, although lighter and resource-efficient, can have varying sustainability credentials depending on the glue and finishing processes used, making bamboo panels a more environmentally robust option overall.

Cost Considerations: Panel vs Veneer

Bamboo panels generally cost more upfront than bamboo veneers due to their thickness and durability, making them ideal for structural applications. Bamboo veneers offer a cost-effective alternative for decorative purposes, as they are thinner and require less raw material. When budgeting, consider that panels provide long-term value through sturdiness, while veneers reduce initial expenses but may need replacement sooner.

Maintenance and Longevity

Bamboo panels offer greater durability and easier maintenance compared to bamboo veneer due to their solid construction, which resists warping and moisture damage. Bamboo veneer, being a thin layer bonded to a substrate, requires more careful handling and specialized cleaning to prevent peeling and deterioration over time. Choosing bamboo panels enhances longevity in high-traffic or moisture-prone areas, ensuring sustained performance and reduced upkeep costs.

Choosing the Right Bamboo Material for Your Project

Bamboo panels offer a solid, stable substrate ideal for structural applications and furniture making, providing durability and uniform thickness. Bamboo veneer, a thin layer sliced from bamboo stalks, is best suited for decorative surfaces and can be applied over various substrates to enhance aesthetic appeal without added bulk. Selecting between bamboo panels and veneer depends on your project's need for strength versus visual finish, ensuring the material aligns with functional and design requirements.

bamboo panel vs bamboo veneer Infographic

materialdif.com

materialdif.com