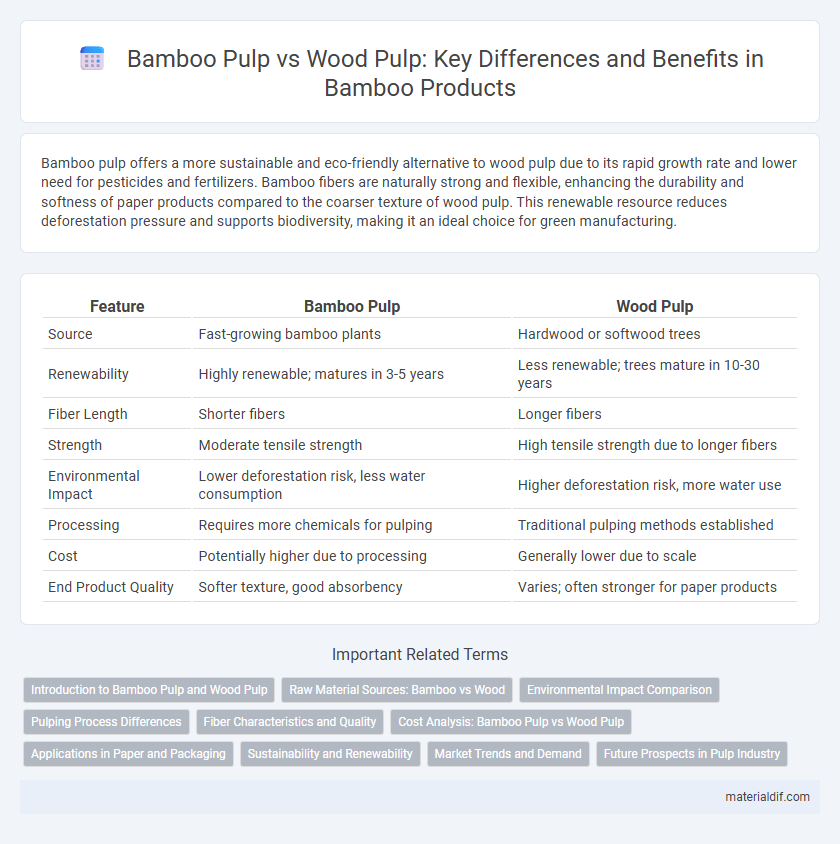

Bamboo pulp offers a more sustainable and eco-friendly alternative to wood pulp due to its rapid growth rate and lower need for pesticides and fertilizers. Bamboo fibers are naturally strong and flexible, enhancing the durability and softness of paper products compared to the coarser texture of wood pulp. This renewable resource reduces deforestation pressure and supports biodiversity, making it an ideal choice for green manufacturing.

Table of Comparison

| Feature | Bamboo Pulp | Wood Pulp |

|---|---|---|

| Source | Fast-growing bamboo plants | Hardwood or softwood trees |

| Renewability | Highly renewable; matures in 3-5 years | Less renewable; trees mature in 10-30 years |

| Fiber Length | Shorter fibers | Longer fibers |

| Strength | Moderate tensile strength | High tensile strength due to longer fibers |

| Environmental Impact | Lower deforestation risk, less water consumption | Higher deforestation risk, more water use |

| Processing | Requires more chemicals for pulping | Traditional pulping methods established |

| Cost | Potentially higher due to processing | Generally lower due to scale |

| End Product Quality | Softer texture, good absorbency | Varies; often stronger for paper products |

Introduction to Bamboo Pulp and Wood Pulp

Bamboo pulp, derived from the fast-growing bamboo grass, offers a sustainable alternative to traditional wood pulp sourced from hardwood and softwood trees. Bamboo pulp contains high cellulose content and natural antimicrobial properties, making it ideal for eco-friendly paper and textile production. Compared to wood pulp, bamboo pulp promotes faster regeneration rates and reduced environmental impact, supporting sustainable forestry practices.

Raw Material Sources: Bamboo vs Wood

Bamboo pulp derives from fast-growing bamboo plants, which mature in 3 to 5 years, offering a highly renewable raw material source compared to traditional wood pulp from slower-growing trees that can take decades to harvest. The cellular structure of bamboo fibers results in a higher yield of pulp per acre, making it a more efficient resource for paper and textile production. Bamboo cultivation requires less water and fewer pesticides than wood plantations, contributing to its sustainability as a raw material.

Environmental Impact Comparison

Bamboo pulp generates significantly lower carbon emissions and requires less water compared to traditional wood pulp, making it a more sustainable raw material for paper and textile production. Its rapid growth cycle allows for faster replenishment without deforestation, preserving biodiversity and reducing habitat loss associated with wood pulp harvesting. Bamboo's natural resistance to pests and diseases also lessens the need for chemical treatments, minimizing soil and water pollution compared to conventional wood sources.

Pulping Process Differences

Bamboo pulp and wood pulp differ significantly in their pulping processes due to the distinct structural compositions of bamboo fibers compared to wood fibers. Bamboo pulping often requires less chemical treatment and shorter cooking times because bamboo has lower lignin content, resulting in a more environmentally friendly process. Wood pulp production typically involves more intensive chemical use and longer processing to break down the tougher, denser wood fibers.

Fiber Characteristics and Quality

Bamboo pulp fibers are generally longer and stronger than wood pulp fibers, providing enhanced tensile strength and durability in paper products. Bamboo fibers have a naturally high cellulose content and lower lignin levels, resulting in a smoother texture and brighter appearance compared to traditional wood pulp. The unique fiber structure of bamboo contributes to increased softness and absorbency, making it an excellent choice for high-quality tissue and textile production.

Cost Analysis: Bamboo Pulp vs Wood Pulp

Bamboo pulp generally offers a cost advantage over wood pulp due to faster growth cycles and higher yield per acre, reducing raw material expenses. Processing bamboo requires less chemical treatment, contributing to lower manufacturing costs compared to traditional wood pulp, which often involves more intensive deforestation and longer growth periods. Economies of scale and regional availability further impact pricing, but bamboo pulp remains a competitively priced, sustainable alternative in the pulp industry.

Applications in Paper and Packaging

Bamboo pulp offers superior strength and sustainability compared to traditional wood pulp, making it ideal for eco-friendly paper and packaging products. It provides higher fiber length and tensile strength, which enhances durability in packaging materials such as cartons and bags. Bamboo pulp's faster growth cycle and lower chemical requirements contribute to its increasing adoption in sustainable packaging and specialty paper production.

Sustainability and Renewability

Bamboo pulp demonstrates superior sustainability and renewability compared to traditional wood pulp due to bamboo's rapid growth rate, reaching maturity in 3-5 years versus decades for most trees. This fast regeneration minimizes deforestation and carbon emissions, while bamboo's natural pest resistance reduces the need for harmful chemicals in cultivation. The efficient use of bamboo as a raw material supports eco-friendly paper production, making it a preferable alternative for sustainable forestry and pulp industries.

Market Trends and Demand

Bamboo pulp is gaining significant traction in the global market due to its faster growth rate and eco-friendly sustainability compared to traditional wood pulp, capturing increasing demand in textile and paper industries. Market trends indicate a growing preference for bamboo pulp fueled by its lower environmental impact, contributing to a surge in investments and research for bamboo-based products. The demand for bamboo pulp is projected to outpace wood pulp growth, driven by consumer awareness and stringent environmental regulations promoting renewable raw materials.

Future Prospects in Pulp Industry

Bamboo pulp offers a sustainable alternative to traditional wood pulp due to its rapid growth rate and lower environmental impact, making it a promising resource for the future pulp industry. Innovations in bamboo processing technology are enhancing fiber quality and reducing production costs, positioning bamboo as a viable substitute in paper and textile manufacturing. The increasing global demand for eco-friendly materials drives investment and research, suggesting significant growth potential for bamboo pulp in the coming decades.

Bamboo pulp vs wood pulp Infographic

materialdif.com

materialdif.com