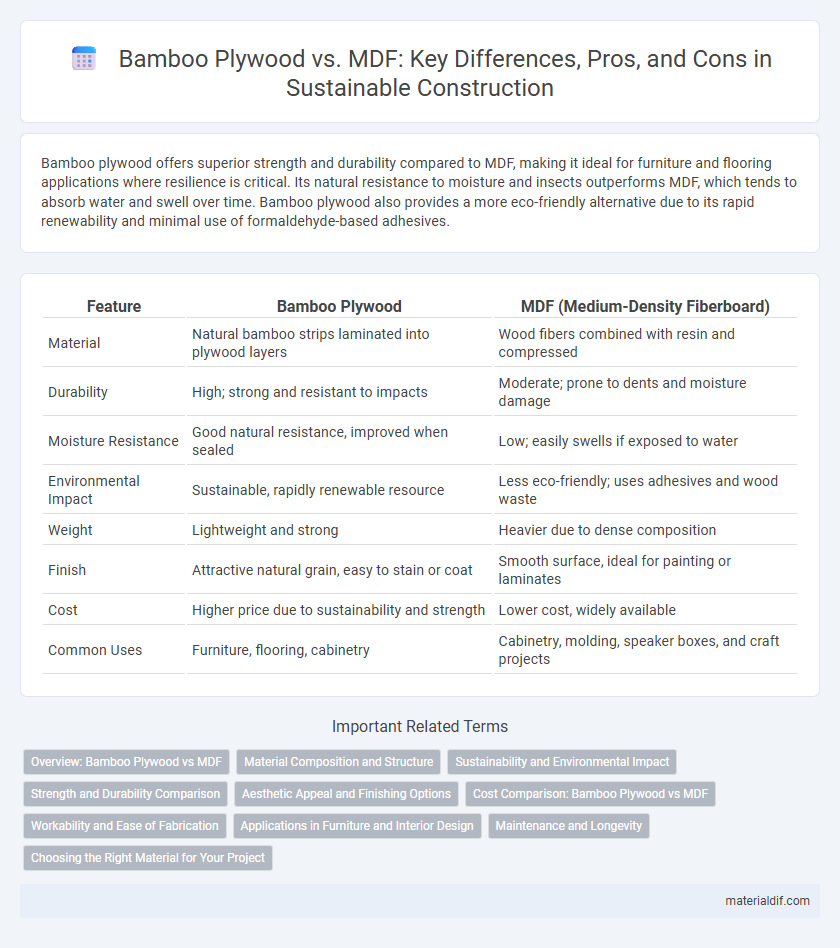

Bamboo plywood offers superior strength and durability compared to MDF, making it ideal for furniture and flooring applications where resilience is critical. Its natural resistance to moisture and insects outperforms MDF, which tends to absorb water and swell over time. Bamboo plywood also provides a more eco-friendly alternative due to its rapid renewability and minimal use of formaldehyde-based adhesives.

Table of Comparison

| Feature | Bamboo Plywood | MDF (Medium-Density Fiberboard) |

|---|---|---|

| Material | Natural bamboo strips laminated into plywood layers | Wood fibers combined with resin and compressed |

| Durability | High; strong and resistant to impacts | Moderate; prone to dents and moisture damage |

| Moisture Resistance | Good natural resistance, improved when sealed | Low; easily swells if exposed to water |

| Environmental Impact | Sustainable, rapidly renewable resource | Less eco-friendly; uses adhesives and wood waste |

| Weight | Lightweight and strong | Heavier due to dense composition |

| Finish | Attractive natural grain, easy to stain or coat | Smooth surface, ideal for painting or laminates |

| Cost | Higher price due to sustainability and strength | Lower cost, widely available |

| Common Uses | Furniture, flooring, cabinetry | Cabinetry, molding, speaker boxes, and craft projects |

Overview: Bamboo Plywood vs MDF

Bamboo plywood offers superior durability and environmental sustainability compared to MDF, as it is made from fast-growing bamboo strips bonded under high pressure. MDF, composed of wood fibers and resin, provides a smooth surface ideal for painting but lacks the natural strength and moisture resistance found in bamboo plywood. Choosing between bamboo plywood and MDF depends on the project requirements for strength, eco-friendliness, and finish quality.

Material Composition and Structure

Bamboo plywood consists of thin layers of bamboo veneer that are laminated together, providing a strong, lightweight, and eco-friendly material with natural grain patterns. MDF, or Medium Density Fiberboard, is made from wood fibers combined with resin and compressed under high heat and pressure, resulting in a smooth but less durable surface compared to bamboo plywood. The natural fibrous structure of bamboo plywood offers better moisture resistance and tensile strength, making it more suitable for furniture and flooring applications than the homogenous, engineered composition of MDF.

Sustainability and Environmental Impact

Bamboo plywood is significantly more sustainable than MDF due to its rapid growth rate and renewable harvesting practices, which reduce deforestation and promote ecosystem balance. Unlike MDF, which relies heavily on synthetic resins and formaldehyde-based adhesives with harmful volatile organic compounds (VOCs), bamboo plywood uses natural adhesives, resulting in a lower environmental footprint and improved indoor air quality. The biodegradability of bamboo plywood and its ability to sequester carbon throughout cultivation further enhance its environmental benefits compared to MDF.

Strength and Durability Comparison

Bamboo plywood offers superior strength and durability compared to MDF due to its natural fiber composition and layered construction, which resists warping and cracking under stress. MDF, being made from compressed wood fibers and resin, tends to be less robust and more prone to water damage and sagging over time. For applications requiring long-lasting structural integrity, bamboo plywood is a more resilient and eco-friendly choice.

Aesthetic Appeal and Finishing Options

Bamboo plywood offers a unique natural grain and warm color that enhances aesthetic appeal, making it ideal for visible furniture and decorative applications. MDF provides a smooth, uniform surface suitable for painting or veneering, allowing versatile finishing options for customized looks. Bamboo plywood's durability supports stains and sealants well, while MDF excels in achieving flawless painted finishes.

Cost Comparison: Bamboo Plywood vs MDF

Bamboo plywood generally costs more than MDF due to its sustainable sourcing and durability, while MDF remains a budget-friendly option ideal for indoor, low-moisture applications. The price per sheet of bamboo plywood ranges from $50 to $100, compared to MDF's average cost of $20 to $40 per sheet. Investing in bamboo plywood often results in longer-lasting surfaces that justify the higher upfront expense compared to MDF's lower initial cost but reduced longevity.

Workability and Ease of Fabrication

Bamboo plywood offers superior workability with its natural grain structure, allowing for easier cutting, sanding, and shaping compared to MDF, which tends to generate more dust and can be prone to edge chipping. The density and durability of bamboo plywood make it ideal for applications requiring precision and strength, while MDF's uniform surface is better suited for smooth finishes but requires careful handling to avoid damage during fabrication. Both materials respond well to common woodworking tools, though bamboo plywood provides a more resilient and stable substrate for intricate projects.

Applications in Furniture and Interior Design

Bamboo plywood offers superior strength and moisture resistance compared to MDF, making it ideal for furniture pieces such as cabinets and tables that demand durability and a natural aesthetic. MDF is best suited for interior design elements like decorative panels and moldings due to its smooth surface and ease of painting. The choice between bamboo plywood and MDF significantly impacts the longevity and visual appeal of furniture and interior installations.

Maintenance and Longevity

Bamboo plywood offers superior durability and resistance to moisture compared to MDF, making it easier to maintain in high-humidity environments. Regular cleaning of bamboo plywood with a damp cloth and mild detergent helps preserve its natural finish and structural integrity for decades. In contrast, MDF requires more careful handling to avoid swelling or warping from water exposure, and its lifespan is generally shorter due to lower moisture resistance.

Choosing the Right Material for Your Project

Bamboo plywood offers superior strength, durability, and environmental sustainability compared to MDF, making it ideal for furniture and cabinetry that require longevity and a natural aesthetic. MDF, known for its smooth surface and affordability, excels in applications needing intricate painting or molding but lacks the moisture resistance and robustness of bamboo plywood. Selecting the right material depends on project needs: bamboo plywood suits structural and eco-conscious designs, while MDF fits budget-friendly, decorative indoor elements.

Bamboo Plywood vs MDF Infographic

materialdif.com

materialdif.com