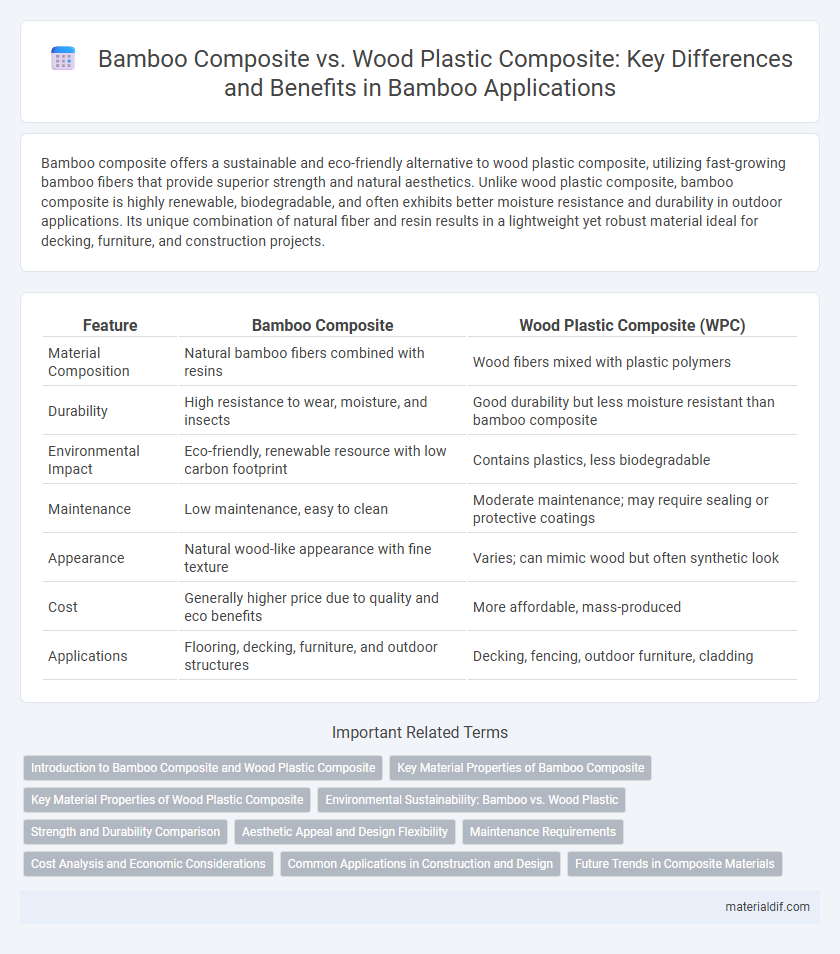

Bamboo composite offers a sustainable and eco-friendly alternative to wood plastic composite, utilizing fast-growing bamboo fibers that provide superior strength and natural aesthetics. Unlike wood plastic composite, bamboo composite is highly renewable, biodegradable, and often exhibits better moisture resistance and durability in outdoor applications. Its unique combination of natural fiber and resin results in a lightweight yet robust material ideal for decking, furniture, and construction projects.

Table of Comparison

| Feature | Bamboo Composite | Wood Plastic Composite (WPC) |

|---|---|---|

| Material Composition | Natural bamboo fibers combined with resins | Wood fibers mixed with plastic polymers |

| Durability | High resistance to wear, moisture, and insects | Good durability but less moisture resistant than bamboo composite |

| Environmental Impact | Eco-friendly, renewable resource with low carbon footprint | Contains plastics, less biodegradable |

| Maintenance | Low maintenance, easy to clean | Moderate maintenance; may require sealing or protective coatings |

| Appearance | Natural wood-like appearance with fine texture | Varies; can mimic wood but often synthetic look |

| Cost | Generally higher price due to quality and eco benefits | More affordable, mass-produced |

| Applications | Flooring, decking, furniture, and outdoor structures | Decking, fencing, outdoor furniture, cladding |

Introduction to Bamboo Composite and Wood Plastic Composite

Bamboo composite combines natural bamboo fibers with resins to create a durable, eco-friendly material known for its high strength-to-weight ratio and resistance to moisture and decay. Wood plastic composite (WPC) blends wood fibers or sawdust with thermoplastics, resulting in a low-maintenance material that offers enhanced weather resistance and dimensional stability compared to traditional wood. Both materials serve as sustainable alternatives in construction and decking, with bamboo composites emphasizing natural fiber benefits while WPC focuses on plastic reinforcement for durability.

Key Material Properties of Bamboo Composite

Bamboo composite offers superior tensile strength and flexibility compared to traditional wood plastic composite (WPC), making it ideal for structural applications. Its natural cellulose fibers provide enhanced moisture resistance and dimensional stability, reducing warping and swelling in humid environments. The eco-friendly profile of bamboo composite includes rapid renewability and biodegradability, setting it apart from synthetic components typically found in WPC materials.

Key Material Properties of Wood Plastic Composite

Wood plastic composite (WPC) combines wood fibers and thermoplastics, offering superior moisture resistance and durability compared to natural bamboo. Its key material properties include high dimensional stability, resistance to rot and insect damage, and low maintenance requirements. WPC also provides enhanced flexibility and impact resistance, making it a versatile alternative in construction and outdoor applications.

Environmental Sustainability: Bamboo vs. Wood Plastic

Bamboo composite offers superior environmental sustainability compared to wood plastic composite due to its rapid growth rate and biodegradability, reducing resource depletion and landfill waste. Bamboo's natural carbon sequestration capabilities lower its overall carbon footprint, whereas wood plastic composites rely heavily on non-renewable petroleum-based plastics. Furthermore, bamboo composites often require fewer chemical treatments, minimizing toxic emissions and enhancing eco-friendliness in construction and manufacturing applications.

Strength and Durability Comparison

Bamboo composite exhibits superior strength and durability compared to wood plastic composite due to its natural cellulose fiber content, which enhances tensile strength and impact resistance. The dense fiber structure of bamboo composites ensures better dimensional stability and resistance to weathering, making them ideal for outdoor applications. In contrast, wood plastic composites often suffer from lower mechanical performance and higher susceptibility to moisture-induced swelling and degradation over time.

Aesthetic Appeal and Design Flexibility

Bamboo composite offers superior aesthetic appeal due to its natural grain and warm tones, closely mimicking traditional wood while providing a more sustainable option. Its high design flexibility allows for intricate shapes and smooth finishes, making it suitable for both modern and rustic applications. Wood plastic composite, although durable, often lacks the authentic texture and rich color variations that bamboo composite naturally presents.

Maintenance Requirements

Bamboo composite requires significantly less maintenance compared to wood plastic composite due to its natural resistance to moisture, insects, and decay, reducing the need for frequent sealing or staining. Wood plastic composite often demands regular cleaning and periodic treatments to prevent mold and UV damage, increasing upkeep costs over time. Both materials benefit from occasional washing, but bamboo composites generally offer superior durability with lower long-term maintenance demands.

Cost Analysis and Economic Considerations

Bamboo composite typically offers a lower production cost compared to wood plastic composite (WPC) due to the rapid renewability and abundance of bamboo biomass, which reduces raw material expenses. Economic considerations favor bamboo composite in markets prioritizing sustainability and cost-efficiency, as it requires less energy-intensive processing and has a shorter growth cycle than timber sources used in WPCs. While initial material costs for WPC can be higher due to plastic resin incorporation and durability enhancements, bamboo composites provide competitive lifecycle cost advantages through faster renewability and lower environmental impact fees.

Common Applications in Construction and Design

Bamboo composite is widely used in decking, flooring, and wall panels due to its natural strength, aesthetic appeal, and sustainability, outperforming wood plastic composite (WPC) in areas requiring eco-friendly material options. Wood plastic composite is commonly applied in outdoor furniture, fencing, and landscaping because of its moisture resistance and ease of maintenance. Both materials serve crucial roles in construction and design, with bamboo composite favored for interior elements and WPC preferred for exterior environments subjected to varying weather conditions.

Future Trends in Composite Materials

Bamboo composite materials are gaining traction over traditional wood plastic composites due to their superior sustainability, faster growth rates, and higher tensile strength. Future trends indicate increased integration of bamboo fibers with bio-based resins to enhance biodegradability and mechanical performance in construction and automotive sectors. Innovations in nanotechnology and eco-friendly processing methods will further elevate bamboo composites, promoting circular economy principles and reducing carbon footprints.

Bamboo composite vs Wood plastic composite Infographic

materialdif.com

materialdif.com