Strand woven bamboo boasts superior strength and durability compared to traditional bamboo owing to its manufacturing process, which compresses bamboo fibers into dense planks. This method enhances resistance to moisture, wear, and impact, making strand woven bamboo ideal for high-traffic flooring and outdoor applications. Traditional bamboo, while natural and aesthetically pleasing, tends to be less dense and more prone to scratching and denting.

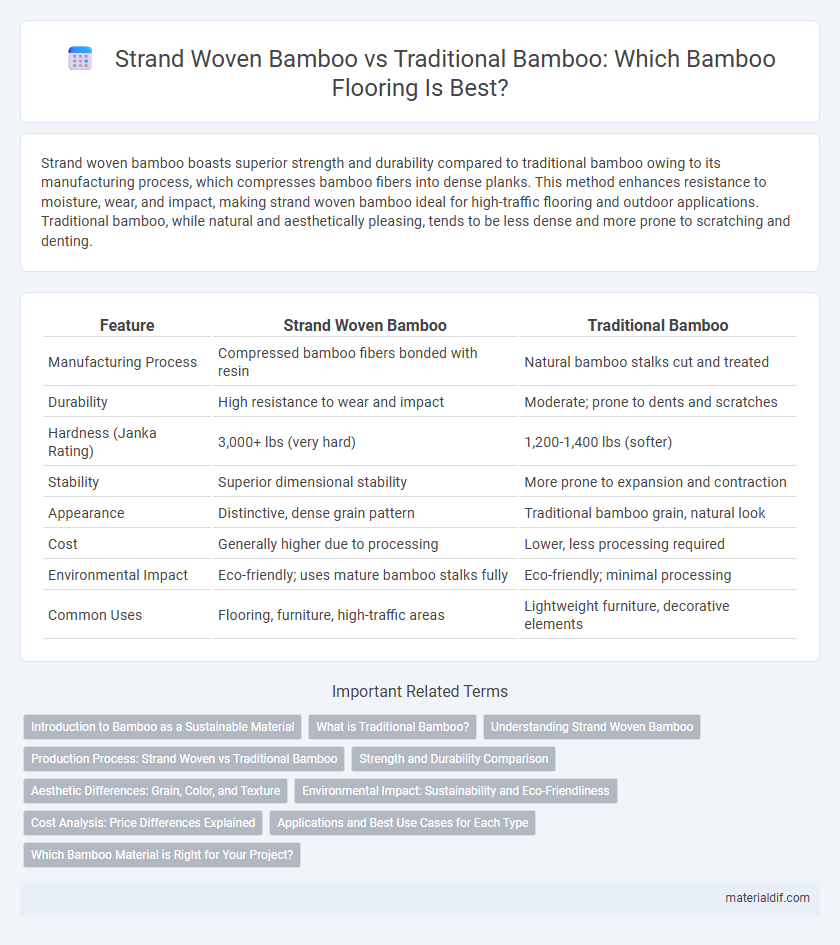

Table of Comparison

| Feature | Strand Woven Bamboo | Traditional Bamboo |

|---|---|---|

| Manufacturing Process | Compressed bamboo fibers bonded with resin | Natural bamboo stalks cut and treated |

| Durability | High resistance to wear and impact | Moderate; prone to dents and scratches |

| Hardness (Janka Rating) | 3,000+ lbs (very hard) | 1,200-1,400 lbs (softer) |

| Stability | Superior dimensional stability | More prone to expansion and contraction |

| Appearance | Distinctive, dense grain pattern | Traditional bamboo grain, natural look |

| Cost | Generally higher due to processing | Lower, less processing required |

| Environmental Impact | Eco-friendly; uses mature bamboo stalks fully | Eco-friendly; minimal processing |

| Common Uses | Flooring, furniture, high-traffic areas | Lightweight furniture, decorative elements |

Introduction to Bamboo as a Sustainable Material

Strand woven bamboo offers enhanced durability and density compared to traditional bamboo, making it a superior choice for sustainable flooring and construction. This engineered product is created by compressing bamboo fibers with adhesives, resulting in a material that is harder and more resistant to wear. Traditional bamboo, while naturally fast-growing and renewable, has varying strength, making strand woven bamboo a more reliable option for long-term sustainability.

What is Traditional Bamboo?

Traditional bamboo refers to bamboo stalks harvested and used in their natural form without extensive processing, retaining their original structure and flexibility. It is commonly utilized in construction, furniture, and crafts due to its strength, lightweight properties, and rapid growth cycle. Unlike strand woven bamboo, traditional bamboo involves minimal modification, preserving its natural aesthetics and organic texture.

Understanding Strand Woven Bamboo

Strand woven bamboo is engineered by compressing shredded bamboo fibers with adhesives under extreme heat and pressure, resulting in a denser and more durable product than traditional bamboo. This manufacturing process enhances its hardness, making strand woven bamboo ideal for high-traffic flooring applications where resistance to dents and scratches is critical. Traditional bamboo, in contrast, retains its natural hollow structure and is less dense, offering flexibility but lower strength and durability.

Production Process: Strand Woven vs Traditional Bamboo

Strand woven bamboo undergoes a process where bamboo fibers are shredded, aligned, and compressed under heat and pressure to create dense, durable planks, offering superior strength and stability compared to traditional bamboo. Traditional bamboo flooring involves slicing the bamboo culms into strips, which are then glued and pressed, resulting in a lighter, less dense material prone to expansion and contraction. The strand woven method enhances resistance to wear and moisture, making it a preferred choice for high-traffic areas and variable climates.

Strength and Durability Comparison

Strand woven bamboo boasts a density of approximately 1,200 kg/m3, significantly higher than traditional bamboo's 600-700 kg/m3, resulting in superior strength and resistance to impact. Its manufacturing process compresses bamboo fibers under extreme heat and pressure, enhancing durability and minimizing susceptibility to moisture and insect damage. Consequently, strand woven bamboo outperforms traditional bamboo in applications requiring long-term structural integrity and wear resistance.

Aesthetic Differences: Grain, Color, and Texture

Strand woven bamboo features a denser, more uniform grain pattern compared to traditional bamboo's natural, linear grain, giving it a bolder, contemporary aesthetic. Its color tends to be richer and more consistent due to the high-pressure manufacturing process, offering shades from deep amber to caramel browns. Texture-wise, strand woven bamboo presents a smoother, harder surface with subtle variations, while traditional bamboo maintains a more natural, organic feel with visible nodes and softer textures.

Environmental Impact: Sustainability and Eco-Friendliness

Strand woven bamboo offers superior sustainability compared to traditional bamboo due to its manufacturing process, which utilizes bamboo fibers compressed under high pressure, resulting in higher density and durability without requiring slower-growing hardwoods. This eco-friendly alternative reduces deforestation, as bamboo is one of the fastest-growing plants, replenishing itself in 3 to 5 years, and its production generates fewer carbon emissions and less waste. The enhanced strength of strand woven bamboo extends the lifespan of flooring and furniture, minimizing the need for frequent replacements and promoting long-term environmental benefits.

Cost Analysis: Price Differences Explained

Strand woven bamboo typically commands a higher price than traditional bamboo due to its manufacturing process, which involves compressing bamboo fibers under extreme heat and pressure to create a denser, more durable material. Traditional bamboo, harvested and used in its natural form, has lower production costs but lacks the enhanced strength and stability found in strand woven bamboo. Cost differences reflect durability, with strand woven bamboo offering greater long-term value despite the initial investment.

Applications and Best Use Cases for Each Type

Strand woven bamboo offers superior density and durability compared to traditional bamboo, making it ideal for high-traffic flooring, heavy-use furniture, and structural applications requiring enhanced strength. Traditional bamboo's natural flexibility and aesthetic variations suit decorative elements, lightweight furniture, and artisanal crafts where appearance and ease of work are prioritized. Both types excel in eco-friendly construction, but strand woven bamboo is preferred for areas demanding maximum wear resistance and longevity.

Which Bamboo Material is Right for Your Project?

Strand woven bamboo offers superior durability and hardness, making it ideal for high-traffic areas and heavy-use projects, surpassing traditional bamboo in strength due to its unique manufacturing process. Traditional bamboo retains more natural aesthetics and flexibility, suited for decorative or lightweight applications where natural grain and texture are desired. Choosing between strand woven and traditional bamboo depends on project requirements such as durability, appearance, and budget, with strand woven providing a more robust, long-lasting material.

Strand woven bamboo vs traditional bamboo Infographic

materialdif.com

materialdif.com