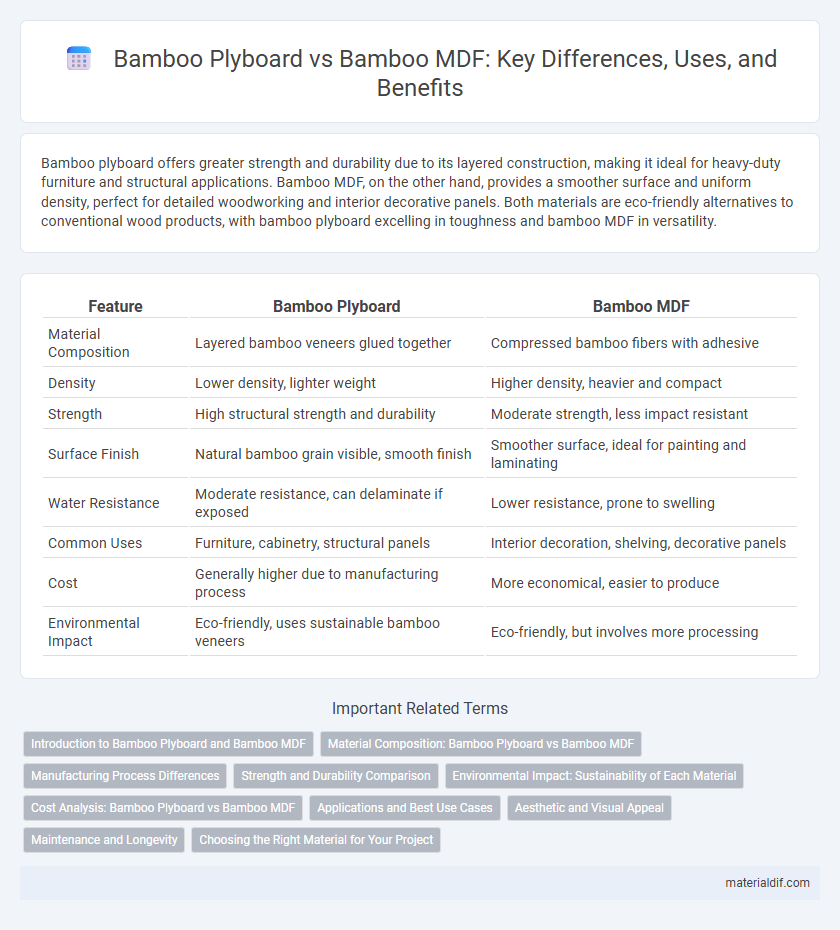

Bamboo plyboard offers greater strength and durability due to its layered construction, making it ideal for heavy-duty furniture and structural applications. Bamboo MDF, on the other hand, provides a smoother surface and uniform density, perfect for detailed woodworking and interior decorative panels. Both materials are eco-friendly alternatives to conventional wood products, with bamboo plyboard excelling in toughness and bamboo MDF in versatility.

Table of Comparison

| Feature | Bamboo Plyboard | Bamboo MDF |

|---|---|---|

| Material Composition | Layered bamboo veneers glued together | Compressed bamboo fibers with adhesive |

| Density | Lower density, lighter weight | Higher density, heavier and compact |

| Strength | High structural strength and durability | Moderate strength, less impact resistant |

| Surface Finish | Natural bamboo grain visible, smooth finish | Smoother surface, ideal for painting and laminating |

| Water Resistance | Moderate resistance, can delaminate if exposed | Lower resistance, prone to swelling |

| Common Uses | Furniture, cabinetry, structural panels | Interior decoration, shelving, decorative panels |

| Cost | Generally higher due to manufacturing process | More economical, easier to produce |

| Environmental Impact | Eco-friendly, uses sustainable bamboo veneers | Eco-friendly, but involves more processing |

Introduction to Bamboo Plyboard and Bamboo MDF

Bamboo plyboard is manufactured by layering thin, woven bamboo veneers with adhesive to create a strong, flexible panel known for its durability and resistance to warping. Bamboo MDF (Medium-Density Fiberboard) is produced by compressing bamboo fibers with resin, resulting in a smooth, uniform surface ideal for fine finishes and intricate woodworking. Both materials capitalize on bamboo's sustainability and fast growth, but plyboard offers greater structural strength while MDF provides superior machinability and surface consistency.

Material Composition: Bamboo Plyboard vs Bamboo MDF

Bamboo plyboard consists of multiple layers of bamboo veneers bonded together with adhesive, offering a strong and flexible panel structure ideal for construction and furniture applications. Bamboo MDF is made by breaking down bamboo fibers into a fine powder, then compressing them with resin and heat to form dense, smooth boards suited for detailed machining and finishes. The layered composition of bamboo plyboard provides superior strength and moisture resistance compared to the uniform, engineered structure of bamboo MDF.

Manufacturing Process Differences

Bamboo plyboard is manufactured by layering thin sheets of bamboo veneer with adhesive and compressing them under high pressure, enhancing strength and durability through cross-grain bonding. Bamboo MDF (Medium Density Fiberboard) is produced by breaking down bamboo fibers into a fine pulp, mixing with resin, and pressing into dense, smooth panels, which results in uniform thickness and surface ideal for painting. The key manufacturing difference lies in plyboard's use of whole veneers for structural integrity versus MDF's fiber-based composition for consistent density.

Strength and Durability Comparison

Bamboo plywood features multiple layers of bamboo veneer glued crosswise, enhancing its tensile strength and resistance to warping compared to bamboo MDF, which consists of compressed bamboo fibers bonded with resin. Bamboo plywood typically offers superior durability and structural integrity, making it ideal for load-bearing applications and furniture that requires long-lasting performance. In contrast, bamboo MDF, while smoother and easier to machine, is less robust and more susceptible to moisture damage and surface wear over time.

Environmental Impact: Sustainability of Each Material

Bamboo plyboard is more sustainable due to its use of whole bamboo strips, which retain the natural fibers and require less adhesive compared to bamboo MDF that involves pulverizing bamboo into fine particles and using higher resin content. The production of bamboo plyboard generally consumes less energy and produces fewer emissions, making it a greener option in terms of carbon footprint. Bamboo MDF, while still eco-friendly, has a higher environmental impact due to the intensive processing and chemical bonding involved in its manufacturing.

Cost Analysis: Bamboo Plyboard vs Bamboo MDF

Bamboo plyboard generally costs more than bamboo MDF due to its layered construction, providing superior strength and durability ideal for structural applications. Bamboo MDF is more affordable, made from compressed bamboo fibers, making it suitable for lightweight furniture and interior decor where cost-efficiency is essential. Evaluating project requirements and budget constraints is crucial for selecting the most cost-effective bamboo material.

Applications and Best Use Cases

Bamboo plyboard offers superior strength and moisture resistance, making it ideal for structural applications like furniture, cabinetry, and flooring where durability is critical. Bamboo MDF, being smoother and denser, excels in interior design elements such as wall panels, decorative laminates, and intricate woodworking projects demanding fine finishes. Both materials leverage bamboo's sustainability, but plyboard suits load-bearing uses while MDF is preferred for aesthetic and detailed craftsmanship.

Aesthetic and Visual Appeal

Bamboo plyboard showcases a natural, layered grain pattern that enhances its aesthetic appeal with a rustic and organic look, ideal for decorative surfaces and visible furniture parts. Bamboo MDF offers a smoother, uniform finish without visible grain, allowing for versatile painting or veneering to achieve sleek, modern designs. Both materials provide distinct visual characteristics, with plyboard emphasizing natural texture and MDF enabling customizable aesthetics.

Maintenance and Longevity

Bamboo plyboard offers superior durability and resistance to warping compared to bamboo MDF, making it ideal for high-traffic areas requiring minimal maintenance. While bamboo MDF features uniform density suitable for detailed finishes, it is more prone to moisture damage and requires careful sealing and upkeep. Longevity of bamboo plyboard typically exceeds that of bamboo MDF due to its layered construction that enhances structural stability and wear resistance.

Choosing the Right Material for Your Project

Bamboo plyboard offers superior strength and durability due to its layered construction, making it ideal for furniture and structural applications requiring high load-bearing capacity. Bamboo MDF, composed of compressed bamboo fibers, provides a smooth surface perfect for intricate designs and interior paneling, though it is less resistant to moisture and heavy use. Selecting between bamboo plyboard and bamboo MDF depends on balancing the need for strength and decorative finish in your specific project requirements.

bamboo plyboard vs bamboo MDF Infographic

materialdif.com

materialdif.com