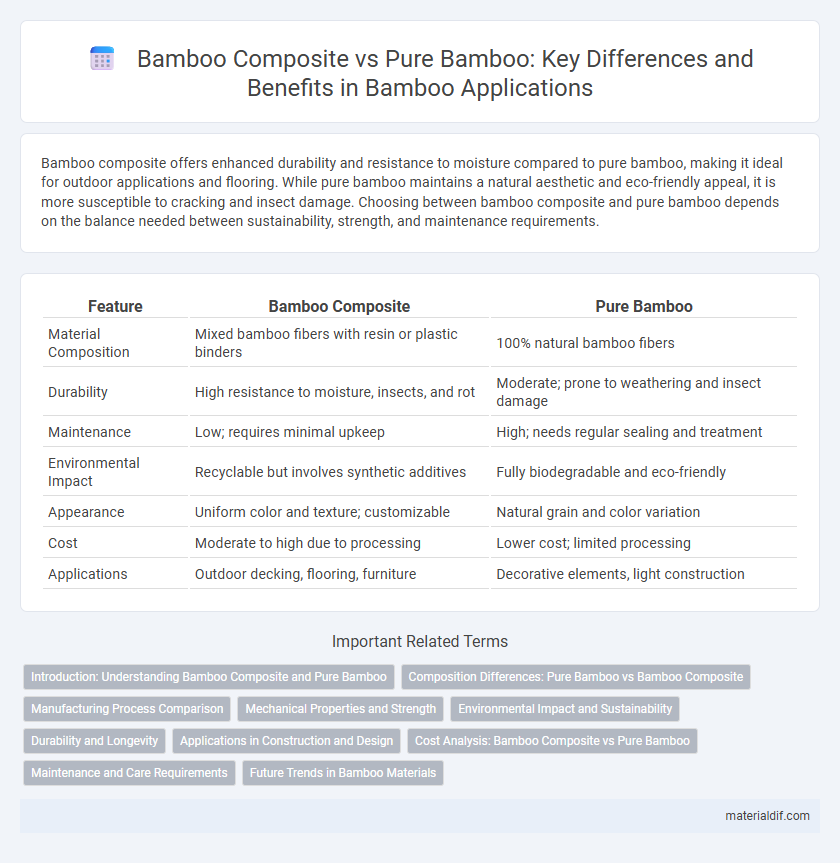

Bamboo composite offers enhanced durability and resistance to moisture compared to pure bamboo, making it ideal for outdoor applications and flooring. While pure bamboo maintains a natural aesthetic and eco-friendly appeal, it is more susceptible to cracking and insect damage. Choosing between bamboo composite and pure bamboo depends on the balance needed between sustainability, strength, and maintenance requirements.

Table of Comparison

| Feature | Bamboo Composite | Pure Bamboo |

|---|---|---|

| Material Composition | Mixed bamboo fibers with resin or plastic binders | 100% natural bamboo fibers |

| Durability | High resistance to moisture, insects, and rot | Moderate; prone to weathering and insect damage |

| Maintenance | Low; requires minimal upkeep | High; needs regular sealing and treatment |

| Environmental Impact | Recyclable but involves synthetic additives | Fully biodegradable and eco-friendly |

| Appearance | Uniform color and texture; customizable | Natural grain and color variation |

| Cost | Moderate to high due to processing | Lower cost; limited processing |

| Applications | Outdoor decking, flooring, furniture | Decorative elements, light construction |

Introduction: Understanding Bamboo Composite and Pure Bamboo

Bamboo composite is engineered by combining natural bamboo fibers with resins or adhesives, enhancing durability and resistance to moisture compared to pure bamboo, which consists of untreated, solid bamboo material. Pure bamboo offers natural aesthetic appeal and sustainability but may lack the uniform strength and longevity found in bamboo composites. Understanding the differences between these materials is essential for applications in construction, furniture, and flooring where performance and environmental impact are critical considerations.

Composition Differences: Pure Bamboo vs Bamboo Composite

Pure bamboo consists entirely of natural bamboo fibers tightly bound together, offering superior strength, flexibility, and biodegradability. Bamboo composite integrates bamboo fibers with synthetic resins or polymers, enhancing durability, water resistance, and dimensional stability but reducing natural biodegradability. The composite material often features a layered structure combining raw bamboo strands with plastic matrices, resulting in improved performance for outdoor applications compared to pure bamboo's more organic composition.

Manufacturing Process Comparison

Bamboo composite involves blending bamboo fibers with resins and adhesives through processes like extrusion or compression molding, enhancing durability and water resistance. Pure bamboo manufacturing focuses on harvesting, drying, and treating bamboo culms with minimal processing to retain natural properties but may result in lower structural uniformity. The composite production requires industrial machinery and chemical additives, while pure bamboo manufacturing emphasizes traditional techniques and environmental sustainability.

Mechanical Properties and Strength

Bamboo composites exhibit enhanced mechanical properties and greater strength compared to pure bamboo, owing to their engineered fiber alignment and resin infusion that improve tensile and flexural strength. Pure bamboo, while naturally strong and flexible, often shows variability in mechanical performance due to natural growth inconsistencies and moisture content. The composite form provides superior durability and resistance to deformation, making it ideal for structural applications requiring consistent load-bearing capacity.

Environmental Impact and Sustainability

Bamboo composite products often incorporate adhesives and resins, which can introduce synthetic chemicals affecting their recyclability and biodegradability, whereas pure bamboo remains fully natural and compostable. The harvesting of pure bamboo promotes faster regrowth and carbon sequestration due to its rapid growth rate and minimal processing requirements, enhancing its sustainability profile. However, bamboo composites may offer increased durability and longevity, potentially reducing resource consumption over time if sourced and manufactured responsibly.

Durability and Longevity

Bamboo composite materials offer enhanced durability and longevity compared to pure bamboo due to their improved resistance to moisture, insects, and environmental wear. Pure bamboo, while naturally strong and flexible, is more prone to cracking, warping, and biodegradation over time without proper treatment. Engineered bamboo composites extend the lifespan of bamboo products, making them suitable for high-traffic and outdoor applications.

Applications in Construction and Design

Bamboo composite materials, combining bamboo fibers with resins or polymers, offer enhanced durability and moisture resistance compared to pure bamboo, making them ideal for structural elements and exterior applications in construction. Pure bamboo retains natural strength and flexibility, favored for traditional frameworks, flooring, and decorative design features where aesthetic and eco-friendliness are prioritized. The superior dimensional stability of bamboo composites supports innovative architectural designs requiring consistent performance under varying environmental conditions.

Cost Analysis: Bamboo Composite vs Pure Bamboo

Bamboo composite typically incurs higher upfront costs compared to pure bamboo due to the additional manufacturing processes and resin materials used in its production, which enhance durability and weather resistance. Pure bamboo offers a more economical option with lower material and processing expenses but may require more maintenance over time, potentially increasing long-term costs. Evaluating total cost of ownership reveals that bamboo composite often provides better value in applications demanding higher performance and longevity.

Maintenance and Care Requirements

Bamboo composite materials demand less maintenance compared to pure bamboo, resisting moisture, pests, and warping due to their engineered composition. Pure bamboo requires regular sealing, cleaning, and protection from humidity to prevent cracking and insect damage. Choosing bamboo composite reduces long-term upkeep while preserving the aesthetic appeal of natural bamboo.

Future Trends in Bamboo Materials

Bamboo composite materials are gaining traction over pure bamboo due to enhanced durability, moisture resistance, and sustainability, aligning with growing environmental regulations. Innovations in bio-based adhesives and nanotechnology improve the structural integrity and lifespan of bamboo composites, making them ideal for construction and automotive industries. Future trends indicate a surge in hybrid bamboo materials combining fibers with advanced polymers, promoting circular economy principles and reduced carbon footprints.

Bamboo composite vs pure bamboo Infographic

materialdif.com

materialdif.com