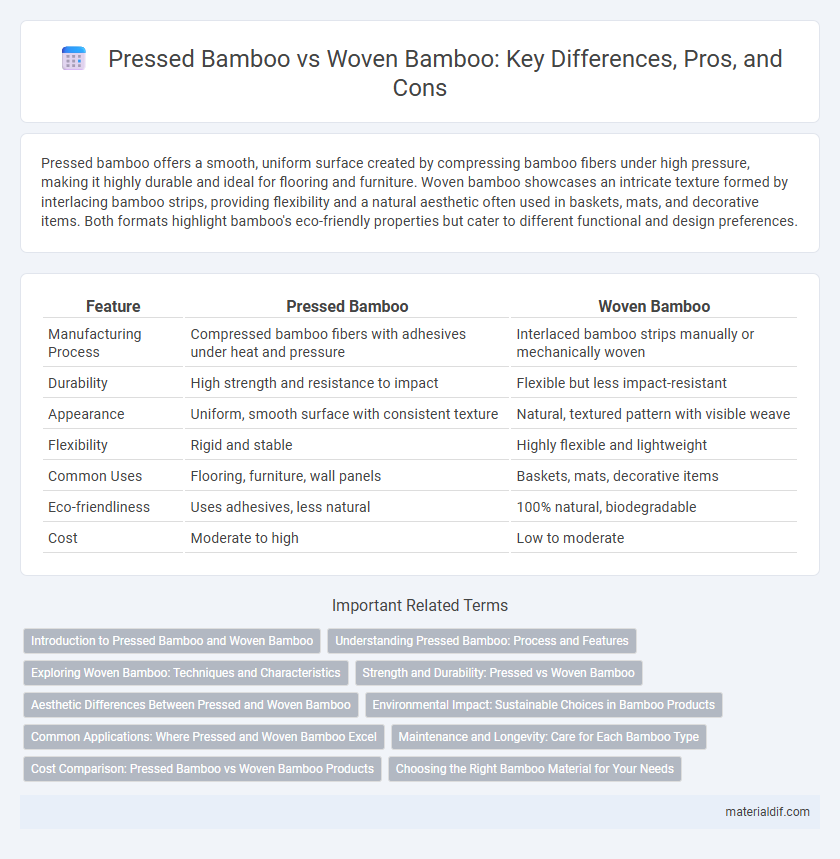

Pressed bamboo offers a smooth, uniform surface created by compressing bamboo fibers under high pressure, making it highly durable and ideal for flooring and furniture. Woven bamboo showcases an intricate texture formed by interlacing bamboo strips, providing flexibility and a natural aesthetic often used in baskets, mats, and decorative items. Both formats highlight bamboo's eco-friendly properties but cater to different functional and design preferences.

Table of Comparison

| Feature | Pressed Bamboo | Woven Bamboo |

|---|---|---|

| Manufacturing Process | Compressed bamboo fibers with adhesives under heat and pressure | Interlaced bamboo strips manually or mechanically woven |

| Durability | High strength and resistance to impact | Flexible but less impact-resistant |

| Appearance | Uniform, smooth surface with consistent texture | Natural, textured pattern with visible weave |

| Flexibility | Rigid and stable | Highly flexible and lightweight |

| Common Uses | Flooring, furniture, wall panels | Baskets, mats, decorative items |

| Eco-friendliness | Uses adhesives, less natural | 100% natural, biodegradable |

| Cost | Moderate to high | Low to moderate |

Introduction to Pressed Bamboo and Woven Bamboo

Pressed bamboo is manufactured by compressing bamboo fibers with adhesives under heat and pressure to form dense, durable boards commonly used in flooring and furniture. Woven bamboo involves intertwining thin bamboo strips into flexible mats or panels, prized for lightweight applications like wall coverings and decorative elements. Both materials showcase bamboo's sustainability but differ in texture, structural properties, and optimal use cases.

Understanding Pressed Bamboo: Process and Features

Pressed bamboo is created by compressing bamboo fibers with adhesive under heat and pressure, resulting in dense, durable panels ideal for flooring and furniture. This process enhances the material's strength and stability while maintaining bamboo's natural aesthetics and eco-friendly properties. Unlike woven bamboo, which is made by interlacing strips, pressed bamboo offers uniform thickness and a smooth surface suitable for versatile applications.

Exploring Woven Bamboo: Techniques and Characteristics

Woven bamboo involves interlacing thin bamboo strips using traditional techniques such as plaiting, twining, and coiling, which enhances flexibility and strength while creating intricate patterns. This method preserves bamboo's natural texture and allows for breathability, making it ideal for furniture, baskets, and decorative items. Unlike pressed bamboo, which is compressed into solid sheets, woven bamboo emphasizes craftsmanship and results in lightweight, durable structures with organic aesthetics.

Strength and Durability: Pressed vs Woven Bamboo

Pressed bamboo exhibits superior strength and durability compared to woven bamboo due to its manufacturing process, which involves compressing bamboo fibers with adhesives into dense, solid sheets. This results in a material highly resistant to warping, cracking, and moisture damage, making it ideal for flooring and heavy-use applications. Woven bamboo, while flexible and aesthetically appealing, tends to be less durable and more susceptible to wear and environmental conditions over time.

Aesthetic Differences Between Pressed and Woven Bamboo

Pressed bamboo features a smooth, uniform surface with subtle grain patterns that offer a modern and sleek appearance ideal for minimalist interiors. Woven bamboo displays intricate textures and natural variations, creating a rustic, handcrafted look that adds warmth and visual interest to any space. The choice between pressed and woven bamboo hinges on desired aesthetic impact, with pressed bamboo emphasizing clean lines and woven bamboo showcasing artisanal detail.

Environmental Impact: Sustainable Choices in Bamboo Products

Pressed bamboo products typically have a lower environmental impact than woven bamboo due to their efficient use of bamboo fibers and reduced waste in manufacturing. Woven bamboo, while biodegradable and renewable, often involves more energy-intensive processes, including the harvesting of older bamboo stalks and manual weaving techniques. Choosing pressed bamboo supports sustainability by maximizing raw material utilization and minimizing carbon emissions during production.

Common Applications: Where Pressed and Woven Bamboo Excel

Pressed bamboo is commonly used in flooring, furniture, and cabinetry due to its high durability and uniform strength, making it ideal for structural applications. Woven bamboo excels in decorative items, wall coverings, and lightweight furniture where flexibility and aesthetic texture are prioritized. Both materials leverage bamboo's sustainability but differ in application based on their physical properties and manufacturing process.

Maintenance and Longevity: Care for Each Bamboo Type

Pressed bamboo requires less frequent sealing and is highly resistant to moisture, making it easier to maintain and ideal for high-traffic areas. Woven bamboo demands regular cleaning and protective treatments to prevent fraying and moisture damage, ensuring its durability over time. Both types benefit from avoiding excessive water exposure and direct sunlight to maximize longevity.

Cost Comparison: Pressed Bamboo vs Woven Bamboo Products

Pressed bamboo products generally cost less than woven bamboo due to the streamlined manufacturing process that uses bamboo fibers compressed under high pressure, reducing labor and production time. Woven bamboo requires skilled artisans to interlace strips meticulously, increasing labor costs and production duration, which results in a higher price point. Consumers often find pressed bamboo items more affordable for large-scale purchases, while woven bamboo offers premium pricing tied to craftsmanship and durability.

Choosing the Right Bamboo Material for Your Needs

Pressed bamboo offers enhanced durability and uniformity, making it ideal for flooring and furniture that require smooth, consistent surfaces. Woven bamboo provides flexibility and breathability, perfect for decorative items, baskets, and lightweight furniture. Selecting between pressed and woven bamboo depends on the specific application, balancing strength with aesthetic and functional requirements.

Pressed bamboo vs woven bamboo Infographic

materialdif.com

materialdif.com