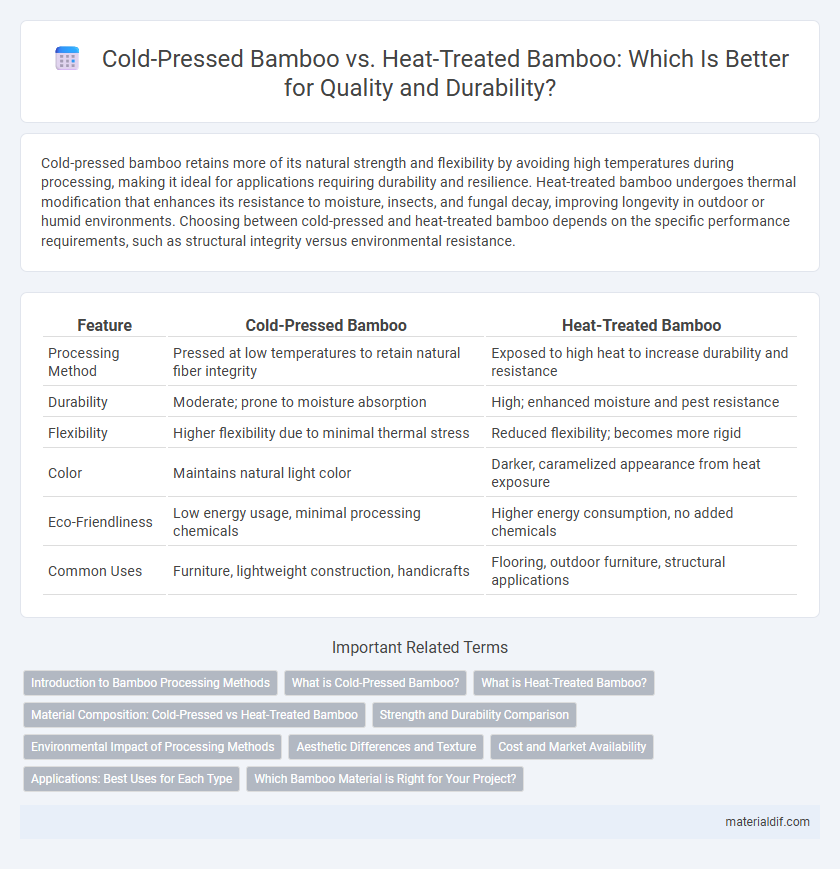

Cold-pressed bamboo retains more of its natural strength and flexibility by avoiding high temperatures during processing, making it ideal for applications requiring durability and resilience. Heat-treated bamboo undergoes thermal modification that enhances its resistance to moisture, insects, and fungal decay, improving longevity in outdoor or humid environments. Choosing between cold-pressed and heat-treated bamboo depends on the specific performance requirements, such as structural integrity versus environmental resistance.

Table of Comparison

| Feature | Cold-Pressed Bamboo | Heat-Treated Bamboo |

|---|---|---|

| Processing Method | Pressed at low temperatures to retain natural fiber integrity | Exposed to high heat to increase durability and resistance |

| Durability | Moderate; prone to moisture absorption | High; enhanced moisture and pest resistance |

| Flexibility | Higher flexibility due to minimal thermal stress | Reduced flexibility; becomes more rigid |

| Color | Maintains natural light color | Darker, caramelized appearance from heat exposure |

| Eco-Friendliness | Low energy usage, minimal processing chemicals | Higher energy consumption, no added chemicals |

| Common Uses | Furniture, lightweight construction, handicrafts | Flooring, outdoor furniture, structural applications |

Introduction to Bamboo Processing Methods

Cold-pressed bamboo processing preserves the natural strength and flexibility of bamboo by applying pressure without heat, maintaining higher levels of cellulose and lignin for enhanced durability. Heat-treated bamboo undergoes controlled thermal modification, which improves its resistance to moisture, pests, and decay by altering its chemical composition and reducing starch content. These distinct processing methods impact the bamboo's structural integrity and suitability for applications like flooring, furniture, and construction.

What is Cold-Pressed Bamboo?

Cold-pressed bamboo is a manufacturing process where bamboo fibers are extracted and compressed without applying heat, preserving the natural strength and flexibility of the material. This technique retains more of the bamboo's organic properties, resulting in a durable product with higher resistance to cracking and warping compared to heat-treated bamboo. Cold-pressed bamboo is especially favored in sustainable construction and eco-friendly furniture for its enhanced structural integrity and minimal environmental impact.

What is Heat-Treated Bamboo?

Heat-treated bamboo undergoes a controlled heating process at temperatures between 160degC to 220degC, altering its chemical structure and enhancing durability and resistance to moisture and pests. This thermal modification darkens the bamboo, improves dimensional stability, and reduces susceptibility to fungal decay compared to cold-pressed bamboo. Heat treatment optimizes bamboo's performance for outdoor applications and flooring by increasing its hardness and lifespan without the use of chemicals.

Material Composition: Cold-Pressed vs Heat-Treated Bamboo

Cold-pressed bamboo retains a higher concentration of natural cellulose fibers and lignin due to minimal processing, resulting in improved tensile strength and flexibility. Heat-treated bamboo undergoes thermal modification, which reduces hemicellulose content, enhancing decay resistance and dimensional stability but slightly compromising mechanical properties. Material composition differences impact performance factors such as moisture absorption, durability, and structural integrity in construction or furniture applications.

Strength and Durability Comparison

Cold-pressed bamboo retains more of its natural fibers, resulting in higher tensile strength and increased flexibility compared to heat-treated bamboo. Heat-treated bamboo undergoes thermal modification that enhances resistance to moisture and insect damage, thus improving long-term durability in outdoor environments. Choosing between cold-pressed and heat-treated bamboo depends on the required balance between raw material strength and environmental resilience.

Environmental Impact of Processing Methods

Cold-pressed bamboo processing involves minimal energy consumption and chemical use, resulting in a lower carbon footprint and reduced environmental pollution compared to heat-treated bamboo. Heat-treated bamboo requires high temperatures that increase energy demand and generate greenhouse gas emissions, contributing to a larger environmental impact. Sustainable bamboo harvesting combined with cold-pressed processing promotes eco-friendly production by preserving natural resources and minimizing waste.

Aesthetic Differences and Texture

Cold-pressed bamboo features a natural, smooth texture that preserves the bamboo's original grain patterns, enhancing its aesthetic appeal with subtle variations and a matte finish. Heat-treated bamboo undergoes thermal modification, resulting in a darker, richer color with a more uniform appearance and slightly rougher texture due to the caramelization of sugars. These differences in processing directly influence the visual warmth and tactile experience, making cold-pressed bamboo ideal for projects emphasizing natural beauty, while heat-treated bamboo suits designs seeking a deeper hue and enhanced durability.

Cost and Market Availability

Cold-pressed bamboo generally incurs higher production costs due to its labor-intensive extraction process, resulting in limited market availability and premium pricing. Heat-treated bamboo tends to be more economical, offering increased durability and broader accessibility across various retail channels. Market demand favors heat-treated bamboo for affordability, while cold-pressed bamboo appeals to niche segments prioritizing natural processing methods.

Applications: Best Uses for Each Type

Cold-pressed bamboo is ideal for delicate applications such as furniture and decorative items where maintaining natural texture and appearance is essential. Heat-treated bamboo offers enhanced durability and moisture resistance, making it perfect for outdoor decking, flooring, and structural components exposed to weather. Selecting the appropriate bamboo type ensures optimal performance and longevity based on specific environmental conditions and usage requirements.

Which Bamboo Material is Right for Your Project?

Cold-pressed bamboo retains its natural strength and eco-friendly properties by avoiding high temperatures, making it ideal for sustainable and lightweight projects. Heat-treated bamboo undergoes thermal modification, enhancing its durability, moisture resistance, and dimensional stability, which suits outdoor or high-humidity applications. Choosing between cold-pressed and heat-treated bamboo depends on your project's exposure to elements and required longevity, with cold-pressed favored for indoor use and heat-treated preferred for tougher, weather-exposed environments.

Cold-pressed bamboo vs Heat-treated bamboo Infographic

materialdif.com

materialdif.com