Bamboo fiber is a natural material derived directly from the bamboo plant, retaining its eco-friendly properties and durability, while bamboo viscose undergoes extensive chemical processing that transforms bamboo into a softer, more pliable fabric. Bamboo fiber offers better breathability and sustainability, making it ideal for eco-conscious textiles, whereas bamboo viscose is prized for its silky texture and moisture-wicking qualities. Choosing between bamboo fiber and bamboo viscose depends on balancing environmental impact with desired fabric softness and performance.

Table of Comparison

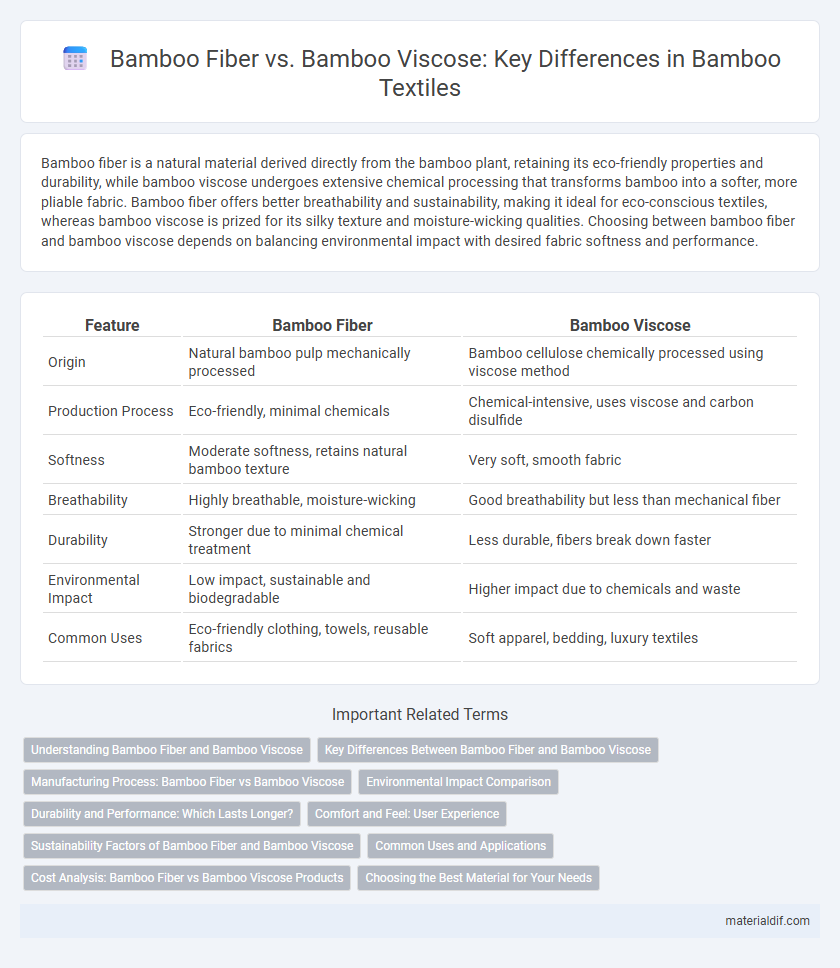

| Feature | Bamboo Fiber | Bamboo Viscose |

|---|---|---|

| Origin | Natural bamboo pulp mechanically processed | Bamboo cellulose chemically processed using viscose method |

| Production Process | Eco-friendly, minimal chemicals | Chemical-intensive, uses viscose and carbon disulfide |

| Softness | Moderate softness, retains natural bamboo texture | Very soft, smooth fabric |

| Breathability | Highly breathable, moisture-wicking | Good breathability but less than mechanical fiber |

| Durability | Stronger due to minimal chemical treatment | Less durable, fibers break down faster |

| Environmental Impact | Low impact, sustainable and biodegradable | Higher impact due to chemicals and waste |

| Common Uses | Eco-friendly clothing, towels, reusable fabrics | Soft apparel, bedding, luxury textiles |

Understanding Bamboo Fiber and Bamboo Viscose

Bamboo fiber is derived directly from the bamboo plant through mechanical processing, retaining its natural strength and eco-friendly properties, making it a sustainable textile option. Bamboo viscose, on the other hand, is produced by chemically treating bamboo pulp to create a softer, silk-like fabric, but this process involves environmentally harmful solvents. Understanding the distinction between bamboo fiber and bamboo viscose is crucial for consumers seeking truly sustainable and biodegradable materials in their textiles.

Key Differences Between Bamboo Fiber and Bamboo Viscose

Bamboo fiber is a natural, mechanically processed material that retains the plant's original properties, offering eco-friendly durability and breathability, while bamboo viscose undergoes chemical processing to convert bamboo pulp into a softer, silk-like fabric with reduced environmental benefits. The production of bamboo fiber involves crushing and retting the bamboo stalks, preserving cellulose naturally, whereas bamboo viscose is produced using sodium hydroxide and carbon disulfide, which impacts its sustainability. Bamboo fiber tends to be coarser and more durable, ideal for eco-conscious textiles, whereas bamboo viscose is smoother and favored for its softness and drape in fashion and bedding.

Manufacturing Process: Bamboo Fiber vs Bamboo Viscose

Bamboo fiber is produced by mechanically crushing bamboo stalks and extracting natural fibers through retting and combing, preserving most of the plant's original cellulose content. Bamboo viscose, however, undergoes a chemical-intensive process where bamboo pulp is dissolved in sodium hydroxide and carbon disulfide to create a viscous solution that is spun into fibers. The manufacturing process of bamboo viscose involves more synthetic chemicals, making it less eco-friendly compared to the more natural extraction method used for bamboo fiber.

Environmental Impact Comparison

Bamboo fiber retains natural antibacterial properties and requires minimal chemicals during processing, resulting in a lower environmental footprint compared to bamboo viscose, which involves intensive chemical treatments like carbon disulfide and sodium hydroxide that contribute to water pollution and air emissions. Bamboo fiber's production consumes less water and energy, making it a more sustainable and eco-friendly option for textile manufacturing. The biodegradability and lower chemical residue of bamboo fiber enhance soil health post-disposal, whereas bamboo viscose can release harmful substances during degradation.

Durability and Performance: Which Lasts Longer?

Bamboo fiber maintains greater durability compared to bamboo viscose due to its less processed, natural state, preserving the structural integrity of the fiber. Bamboo viscose undergoes chemical treatments that weaken the fibers, resulting in reduced longevity and performance under frequent use and washing. Consequently, bamboo fiber garments tend to last longer and retain their quality better than those made from bamboo viscose.

Comfort and Feel: User Experience

Bamboo fiber offers a natural, breathable texture that enhances comfort by allowing better air circulation and moisture absorption. Bamboo viscose, though derived from bamboo, undergoes chemical processing that creates a softer, silk-like feel but may reduce its inherent breathability. Users typically experience bamboo fiber as more eco-friendly and resilient, while bamboo viscose provides a smoother, more luxurious touch against the skin.

Sustainability Factors of Bamboo Fiber and Bamboo Viscose

Bamboo fiber is derived directly from the bamboo plant through a mechanical process, making it more sustainable due to lower chemical use and reduced environmental impact. Bamboo viscose involves a chemically intensive process that breaks down bamboo into a pulp before regeneration into fibers, resulting in higher water and chemical consumption. The sustainability factors favor bamboo fiber for its eco-friendly production, while bamboo viscose has a larger carbon footprint despite its softness and versatility.

Common Uses and Applications

Bamboo fiber, derived from mechanical processing, is commonly used in textiles like towels, bedding, and eco-friendly clothing due to its natural strength and breathability. Bamboo viscose, produced through chemical processing, is widely applied in soft, silky fabrics such as fashion apparel, lingerie, and upholstery because of its smooth texture and vibrant dye retention. Both materials are favored in sustainable product lines, but bamboo fiber emphasizes durability while bamboo viscose prioritizes luxurious comfort and appearance.

Cost Analysis: Bamboo Fiber vs Bamboo Viscose Products

Bamboo fiber products typically incur higher manufacturing costs due to the mechanical processing involved, which preserves natural fiber strength without extensive chemical treatment. Bamboo viscose, produced through chemical-intensive processes like the viscose method, reduces raw material expenses and allows mass production, resulting in lower retail prices. The cost analysis highlights a trade-off between premium durability of bamboo fiber items and the affordability and scalability of bamboo viscose alternatives.

Choosing the Best Material for Your Needs

Bamboo fiber, derived from mechanically crushed bamboo plants, offers natural breathability and durability, making it ideal for eco-friendly textiles. Bamboo viscose, chemically processed to create a softer and more silk-like fabric, provides enhanced moisture-wicking properties suitable for activewear and bedding. Selecting between bamboo fiber and bamboo viscose depends on prioritizing sustainability and toughness versus softness and comfort for specific applications.

Bamboo fiber vs Bamboo viscose Infographic

materialdif.com

materialdif.com