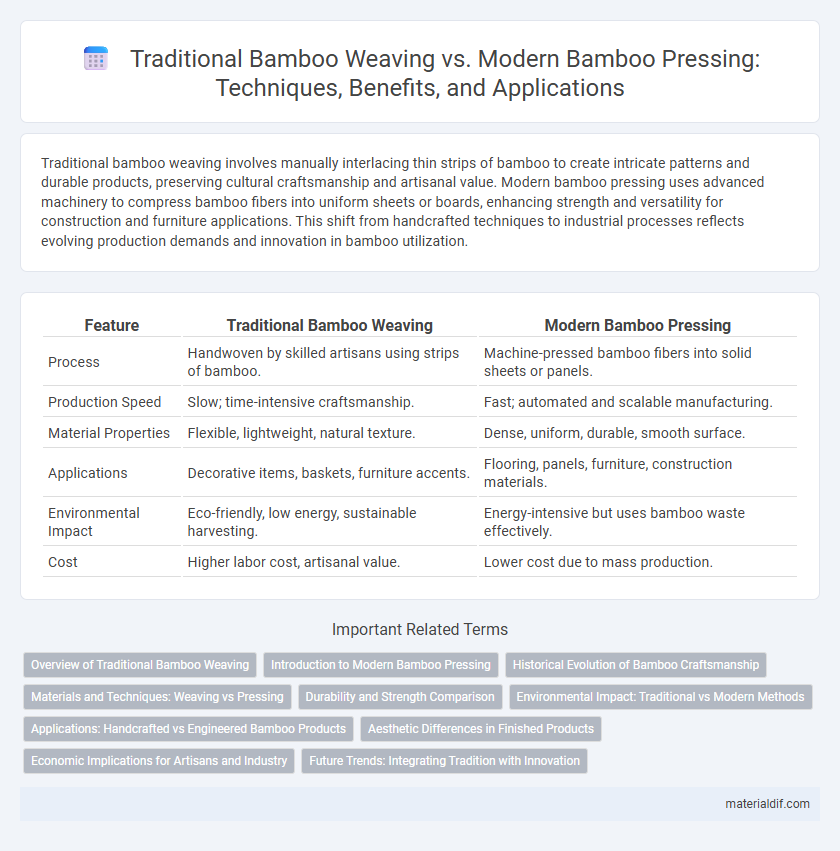

Traditional bamboo weaving involves manually interlacing thin strips of bamboo to create intricate patterns and durable products, preserving cultural craftsmanship and artisanal value. Modern bamboo pressing uses advanced machinery to compress bamboo fibers into uniform sheets or boards, enhancing strength and versatility for construction and furniture applications. This shift from handcrafted techniques to industrial processes reflects evolving production demands and innovation in bamboo utilization.

Table of Comparison

| Feature | Traditional Bamboo Weaving | Modern Bamboo Pressing |

|---|---|---|

| Process | Handwoven by skilled artisans using strips of bamboo. | Machine-pressed bamboo fibers into solid sheets or panels. |

| Production Speed | Slow; time-intensive craftsmanship. | Fast; automated and scalable manufacturing. |

| Material Properties | Flexible, lightweight, natural texture. | Dense, uniform, durable, smooth surface. |

| Applications | Decorative items, baskets, furniture accents. | Flooring, panels, furniture, construction materials. |

| Environmental Impact | Eco-friendly, low energy, sustainable harvesting. | Energy-intensive but uses bamboo waste effectively. |

| Cost | Higher labor cost, artisanal value. | Lower cost due to mass production. |

Overview of Traditional Bamboo Weaving

Traditional bamboo weaving involves intricate handcrafting techniques where skilled artisans interlace thin bamboo strips to create durable, flexible products like baskets, mats, and furniture. This method emphasizes natural materials and cultural heritage, preserving regional patterns and craftsmanship passed down through generations. It contrasts with modern bamboo pressing, which uses mechanical processes to form bamboo sheets or blocks for industrial applications.

Introduction to Modern Bamboo Pressing

Modern bamboo pressing revolutionizes traditional bamboo weaving by using automated machinery to compress bamboo fibers into durable sheets and panels, enhancing production efficiency and product uniformity. This method improves material strength and allows for the creation of versatile building materials, furniture, and decorative items with consistent quality. Unlike handcrafted weaving, modern pressing reduces labor intensity and supports large-scale industrial applications while preserving bamboo's natural sustainability benefits.

Historical Evolution of Bamboo Craftsmanship

Traditional bamboo weaving, an ancient art dating back thousands of years in Asian cultures, relies on handcrafting techniques that emphasize flexibility and intricate patterns. Modern bamboo pressing, emerging in the 20th century, uses industrial machinery to compress bamboo fibers into durable sheets for mass production, enhancing material strength and uniformity. This evolution reflects a shift from artisanal craftsmanship to scalable manufacturing, preserving cultural heritage while meeting contemporary industrial demands.

Materials and Techniques: Weaving vs Pressing

Traditional bamboo weaving utilizes flexible bamboo strips carefully split and soaked to enhance pliability, allowing intricate handwoven patterns that emphasize craftsmanship and cultural heritage. Modern bamboo pressing employs thin bamboo veneers pressed under heat and pressure to form uniform sheets, optimizing efficiency and enabling mass production for industrial applications. The contrasting techniques highlight the shift from artisanal manual weaving to technologically advanced pressing, impacting material properties such as texture, strength, and versatility.

Durability and Strength Comparison

Traditional bamboo weaving creates flexible and resilient structures by interlacing bamboo strips, enhancing tensile strength and shock absorption ideal for baskets and mats. Modern bamboo pressing compresses bamboo fibers into dense, uniform panels, significantly increasing hardness, load-bearing capacity, and resistance to impact, making it suitable for flooring and structural applications. While woven bamboo excels in flexibility and breathability, pressed bamboo offers superior durability and strength for heavy-duty use.

Environmental Impact: Traditional vs Modern Methods

Traditional bamboo weaving employs manual techniques that minimize energy consumption and generate little to no pollution, making it highly sustainable and eco-friendly. Modern bamboo pressing involves mechanized processes that often rely on chemical adhesives and increased energy use, contributing to higher carbon emissions and environmental degradation. The preservation of traditional weaving supports biodiversity and reduces waste, whereas modern pressing can lead to habitat disruption and increased resource extraction.

Applications: Handcrafted vs Engineered Bamboo Products

Traditional bamboo weaving produces artisanal items like baskets, mats, and furniture, emphasizing cultural heritage and intricate craftsmanship. Modern bamboo pressing techniques enable the creation of engineered bamboo products such as flooring, panels, and laminated beams, offering enhanced durability and uniformity. Handcrafted bamboo products highlight aesthetic and functional uniqueness, while engineered bamboo caters to large-scale industrial applications with consistent quality.

Aesthetic Differences in Finished Products

Traditional bamboo weaving produces intricate, textured patterns with natural variations that highlight artisanal craftsmanship, resulting in visually rich and tactile finished products. Modern bamboo pressing yields sleek, uniform surfaces with consistent color and smooth finishes, emphasizing minimalism and contemporary design. The aesthetic contrast lies in the handmade complexity and organic appeal of weaving versus the streamlined, polished look achieved through pressing techniques.

Economic Implications for Artisans and Industry

Traditional bamboo weaving sustains artisans by preserving cultural heritage and enabling handcrafted product differentiation, often commanding premium prices in niche markets. Modern bamboo pressing increases production efficiency and scalability, reducing labor costs but potentially marginalizing skilled weavers and diminishing artisan income. The economic implications highlight a trade-off between preserving artisanal craftsmanship and achieving industrial-scale cost competitiveness in the bamboo sector.

Future Trends: Integrating Tradition with Innovation

Traditional bamboo weaving preserves intricate craftsmanship and cultural heritage through handwoven patterns, while modern bamboo pressing leverages technological advances to produce uniform, durable materials efficiently. Emerging future trends emphasize the fusion of these methods by incorporating digital design tools and sustainable adhesives to enhance product versatility without compromising artisanal value. This integration supports eco-friendly construction, fashion, and interior design industries by offering innovative, high-quality bamboo solutions that honor tradition.

Traditional bamboo weaving vs modern bamboo pressing Infographic

materialdif.com

materialdif.com