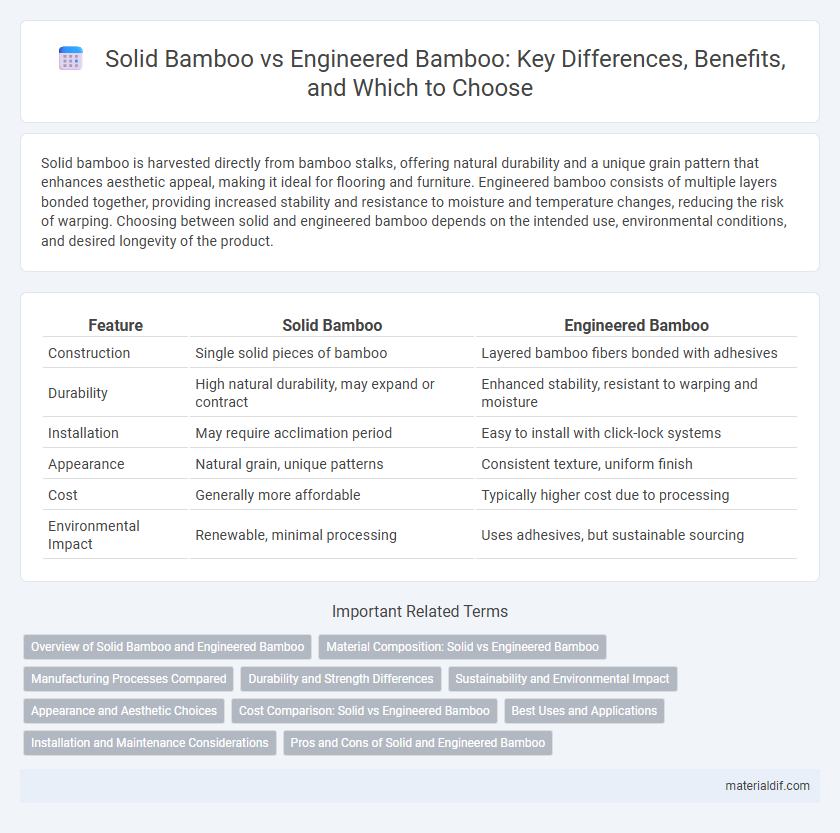

Solid bamboo is harvested directly from bamboo stalks, offering natural durability and a unique grain pattern that enhances aesthetic appeal, making it ideal for flooring and furniture. Engineered bamboo consists of multiple layers bonded together, providing increased stability and resistance to moisture and temperature changes, reducing the risk of warping. Choosing between solid and engineered bamboo depends on the intended use, environmental conditions, and desired longevity of the product.

Table of Comparison

| Feature | Solid Bamboo | Engineered Bamboo |

|---|---|---|

| Construction | Single solid pieces of bamboo | Layered bamboo fibers bonded with adhesives |

| Durability | High natural durability, may expand or contract | Enhanced stability, resistant to warping and moisture |

| Installation | May require acclimation period | Easy to install with click-lock systems |

| Appearance | Natural grain, unique patterns | Consistent texture, uniform finish |

| Cost | Generally more affordable | Typically higher cost due to processing |

| Environmental Impact | Renewable, minimal processing | Uses adhesives, but sustainable sourcing |

Overview of Solid Bamboo and Engineered Bamboo

Solid bamboo consists of whole bamboo stalks that are harvested, dried, and treated to create durable, natural materials ideal for flooring and furniture. Engineered bamboo is made by compressing bamboo fibers or strips with adhesives into layered panels, offering enhanced stability and resistance to moisture compared to solid bamboo. Both types provide eco-friendly alternatives to hardwood, with solid bamboo emphasizing natural aesthetics and engineered bamboo prioritizing structural performance.

Material Composition: Solid vs Engineered Bamboo

Solid bamboo consists of natural bamboo fibers compressed into dense sheets, offering high durability and natural aesthetics with minimal processing. Engineered bamboo is manufactured by layering bamboo veneers or fibers with adhesives, creating a more stable and versatile material resistant to warping and expansion. The key difference lies in solid bamboo's single-material composition versus engineered bamboo's composite structure, which enhances performance and design flexibility.

Manufacturing Processes Compared

Solid bamboo is crafted by harvesting mature bamboo stalks, cutting them into strips, and then compressing them under heat and pressure to form dense, durable planks without additional adhesives. Engineered bamboo involves slicing bamboo into thin veneers or fibers, which are then bonded together with adhesives and resins through lamination or extrusion to create composite boards with enhanced stability and resistance to moisture. The manufacturing process of engineered bamboo allows for more uniformity and customization in size and performance, whereas solid bamboo maintains more natural grain patterns but can be prone to expansion and contraction.

Durability and Strength Differences

Solid bamboo offers exceptional natural strength and durability due to its dense fiber structure, making it highly resistant to impact and wear. Engineered bamboo combines layers of bamboo veneers bonded with adhesives, enhancing dimensional stability and reducing susceptibility to moisture and warping. While solid bamboo excels in raw toughness, engineered bamboo provides more consistent performance in varied environmental conditions, especially in flooring and construction applications.

Sustainability and Environmental Impact

Solid bamboo offers exceptional sustainability due to its rapid growth rate and minimal processing, resulting in a lower carbon footprint compared to traditional hardwoods. Engineered bamboo, created by binding bamboo fibers with adhesives, extends material versatility but may involve chemicals that affect its environmental impact. Choosing solid bamboo maximizes eco-friendliness, while engineered bamboo provides structural advantages with potential trade-offs in chemical usage and recyclability.

Appearance and Aesthetic Choices

Solid bamboo flooring offers a natural, authentic grain pattern with unique color variations that enhance rustic and traditional aesthetics. Engineered bamboo provides consistent color and texture due to its layered construction, allowing for sleek, modern finishes and greater design flexibility. Both types accommodate various staining and finishing options, but engineered bamboo is favored for uniform appearance in contemporary interior designs.

Cost Comparison: Solid vs Engineered Bamboo

Solid bamboo typically costs more upfront due to its natural harvesting and minimal processing requirements, making it a premium option for flooring and furniture. Engineered bamboo, produced by layering bamboo veneers with adhesive and backing materials, offers a more budget-friendly alternative with greater dimensional stability and resistance to moisture. Cost differences vary by quality and manufacturer, but engineered bamboo generally presents better value for large-scale projects without compromising on durability.

Best Uses and Applications

Solid bamboo offers superior strength and durability, making it ideal for structural components, flooring, and furniture that require high load-bearing capacity. Engineered bamboo, created by laminating bamboo fibers, provides enhanced stability and moisture resistance, perfect for applications in cabinetry, wall panels, and decorative surfaces. Selecting between solid and engineered bamboo depends on whether the project prioritizes robustness or dimensional stability in varying environmental conditions.

Installation and Maintenance Considerations

Solid bamboo flooring requires precise acclimatization before installation to prevent warping and is typically nailed or stapled down, demanding professional expertise. Engineered bamboo features a multi-layered construction that allows for simpler floating installation methods and better moisture resistance. Maintenance for solid bamboo involves careful refinishing to preserve its natural look, while engineered bamboo flooring offers easier upkeep with surface refinishing and enhanced durability against humidity.

Pros and Cons of Solid and Engineered Bamboo

Solid bamboo offers exceptional durability and natural aesthetic appeal, making it ideal for high-traffic areas, but it can be susceptible to moisture and temperature fluctuations leading to potential warping. Engineered bamboo provides enhanced stability and moisture resistance due to its multi-layer construction, suitable for installation over concrete subfloors and radiant heating systems, though it may have a shorter lifespan compared to solid bamboo. Both types require proper maintenance to maximize longevity, with solid bamboo favored for traditional applications and engineered bamboo preferred for modern, versatile flooring solutions.

Solid bamboo vs Engineered bamboo Infographic

materialdif.com

materialdif.com