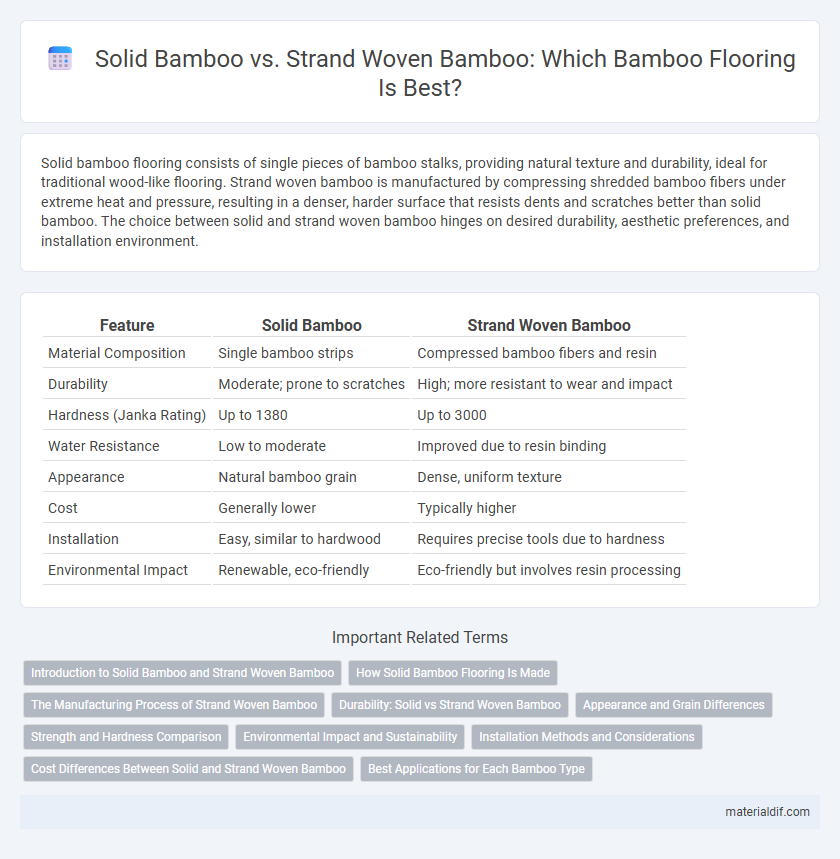

Solid bamboo flooring consists of single pieces of bamboo stalks, providing natural texture and durability, ideal for traditional wood-like flooring. Strand woven bamboo is manufactured by compressing shredded bamboo fibers under extreme heat and pressure, resulting in a denser, harder surface that resists dents and scratches better than solid bamboo. The choice between solid and strand woven bamboo hinges on desired durability, aesthetic preferences, and installation environment.

Table of Comparison

| Feature | Solid Bamboo | Strand Woven Bamboo |

|---|---|---|

| Material Composition | Single bamboo strips | Compressed bamboo fibers and resin |

| Durability | Moderate; prone to scratches | High; more resistant to wear and impact |

| Hardness (Janka Rating) | Up to 1380 | Up to 3000 |

| Water Resistance | Low to moderate | Improved due to resin binding |

| Appearance | Natural bamboo grain | Dense, uniform texture |

| Cost | Generally lower | Typically higher |

| Installation | Easy, similar to hardwood | Requires precise tools due to hardness |

| Environmental Impact | Renewable, eco-friendly | Eco-friendly but involves resin processing |

Introduction to Solid Bamboo and Strand Woven Bamboo

Solid bamboo consists of whole bamboo stalks cut into strips and glued together, offering natural durability and a smooth texture ideal for flooring and furniture. Strand woven bamboo is manufactured by shredding bamboo fibers and compressing them under high pressure with adhesives, resulting in a denser, harder material with enhanced resistance to wear and moisture. Both types provide sustainable alternatives to traditional hardwood, but strand woven bamboo excels in strength and lifespan due to its engineered structure.

How Solid Bamboo Flooring Is Made

Solid bamboo flooring is crafted from natural bamboo stalks that are harvested, cut into strips, and then dried to reduce moisture content. These strips are milled and glued together in a vertical or horizontal grain pattern, pressed under high heat and pressure to form solid planks. This manufacturing process preserves the bamboo's natural density and durability, making solid bamboo a sustainable and resilient flooring option.

The Manufacturing Process of Strand Woven Bamboo

Strand woven bamboo is produced by shredding bamboo fibers, blending them with adhesive resins, and compressing the mixture under high heat and pressure to form dense, durable planks. This manufacturing process enhances the material's hardness, often exceeding traditional hardwoods, and maximizes the utilization of bamboo stalks. The result is a stable, eco-friendly flooring option with superior strength and resistance to moisture compared to solid bamboo.

Durability: Solid vs Strand Woven Bamboo

Solid bamboo offers natural strength with a Janka hardness rating of approximately 1,380, making it durable for residential use but more prone to scratches and dents compared to strand woven bamboo. Strand woven bamboo undergoes a heat and pressure process that compresses bamboo fibers, achieving a Janka hardness rating up to 3,800, which enhances resistance to wear, dents, and moisture. This higher durability makes strand woven bamboo ideal for high-traffic areas and commercial applications where long-lasting flooring is essential.

Appearance and Grain Differences

Solid bamboo features a natural, uniform grain pattern with visible nodes and variations that highlight its organic origin, offering a warm, authentic look. Strand woven bamboo is created by compressing shredded bamboo fibers, resulting in a dense, darker, and more consistent grain structure that appears more uniform and less natural than solid bamboo. The appearance of strand woven bamboo tends to be more industrial and modern, while solid bamboo showcases a traditional, rustic charm due to its distinctive grain and color variations.

Strength and Hardness Comparison

Solid bamboo consists of natural bamboo strips that retain the plant's original density, offering substantial hardness typically rated around 3,000 on the Janka scale. Strand woven bamboo undergoes a specialized compression process that combines shredded bamboo fibers, resulting in a significantly denser and harder material with Janka hardness values often exceeding 4,300. This process enhances strand woven bamboo's strength, making it more resistant to dents and wear compared to solid bamboo.

Environmental Impact and Sustainability

Solid bamboo is harvested directly from mature bamboo stalks, making it a renewable resource with a lower carbon footprint due to minimal processing and natural biodegradability. Strand woven bamboo undergoes a more intensive manufacturing process involving shredding and pressing bamboo fibers, which increases durability but also consumes more energy and may involve adhesives with environmental impacts. Both materials contribute to sustainable flooring solutions, but solid bamboo offers greater eco-friendliness by minimizing industrial processing and chemical use.

Installation Methods and Considerations

Solid bamboo flooring is generally easier to install using traditional methods such as tongue-and-groove or nail-down installation, making it ideal for both DIY projects and professional installers. Strand woven bamboo requires more precise handling due to its density and hardness, often necessitating specialized adhesives or floating floor systems to accommodate its stability and reduce expansion risks. Careful subfloor preparation and moisture control are crucial for both types to ensure long-lasting performance and prevent warping or gapping.

Cost Differences Between Solid and Strand Woven Bamboo

Solid bamboo flooring generally costs between $3 and $7 per square foot, making it a more affordable option for budget-conscious buyers. Strand woven bamboo, created by compressing bamboo fibers under high pressure, typically ranges from $6 to $12 per square foot, reflecting its enhanced durability and density. The higher manufacturing complexity of strand woven bamboo contributes to its increased price compared to solid bamboo.

Best Applications for Each Bamboo Type

Solid bamboo offers exceptional durability and natural aesthetics, making it ideal for indoor flooring, furniture, and cabinetry where a traditional wood appearance is desired. Strand woven bamboo features higher density and greater hardness, which makes it best suited for high-traffic areas, commercial spaces, and outdoor applications requiring superior strength and moisture resistance. Each type caters to specific structural and design needs, optimizing performance based on environment and usage intensity.

Solid bamboo vs Strand woven bamboo Infographic

materialdif.com

materialdif.com