Bamboo chipboard offers superior durability and eco-friendliness compared to particle board, making it an ideal choice for sustainable furniture. It is manufactured using fast-growing bamboo fibers that provide enhanced strength and moisture resistance. Particle board, on the other hand, is composed of wood particles bonded with adhesive, which tends to have lower density and durability.

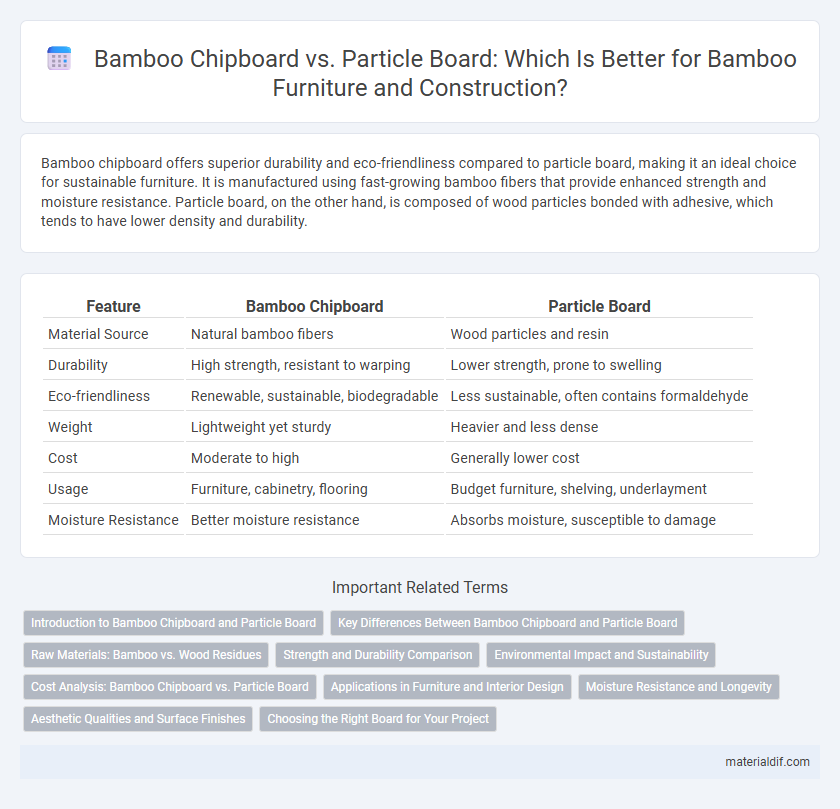

Table of Comparison

| Feature | Bamboo Chipboard | Particle Board |

|---|---|---|

| Material Source | Natural bamboo fibers | Wood particles and resin |

| Durability | High strength, resistant to warping | Lower strength, prone to swelling |

| Eco-friendliness | Renewable, sustainable, biodegradable | Less sustainable, often contains formaldehyde |

| Weight | Lightweight yet sturdy | Heavier and less dense |

| Cost | Moderate to high | Generally lower cost |

| Usage | Furniture, cabinetry, flooring | Budget furniture, shelving, underlayment |

| Moisture Resistance | Better moisture resistance | Absorbs moisture, susceptible to damage |

Introduction to Bamboo Chipboard and Particle Board

Bamboo chipboard is an eco-friendly engineered wood product made from compressed bamboo fibers, offering superior strength and durability compared to traditional particle board, which is manufactured using wood chips, sawdust, and resin. Bamboo chipboard provides a more sustainable and renewable alternative due to bamboo's rapid growth rate and natural hardness. Particle board, while cost-effective and widely used in low-load applications, tends to be less resistant to moisture and wear than bamboo chipboard.

Key Differences Between Bamboo Chipboard and Particle Board

Bamboo chipboard is made from bamboo fibers pressed into dense, durable panels, offering superior strength and sustainability compared to particle board, which is produced from wood chips and resin. Bamboo chipboard exhibits higher resistance to moisture and warping, making it ideal for furniture and flooring applications in humid environments. Particle board is generally more affordable but less durable and prone to damage from water exposure, limiting its use to indoor, low-stress applications.

Raw Materials: Bamboo vs. Wood Residues

Bamboo chipboard is made primarily from fast-growing bamboo stalks, which provide a renewable and sustainable raw material with high strength and natural durability. In contrast, particle board typically uses wood residues such as sawdust, wood chips, and shavings from hardwood or softwood trees, often resulting in lower structural integrity. The use of bamboo as a raw material reduces reliance on traditional timber resources, supporting eco-friendly production and minimizing deforestation impacts.

Strength and Durability Comparison

Bamboo chipboard offers superior strength and durability compared to traditional particle board due to its dense, fibrous structure and natural resilience. It exhibits higher resistance to impact, moisture, and wear, making it ideal for furniture and flooring applications requiring long-lasting performance. In contrast, particle board tends to be more prone to swelling and damage when exposed to moisture, resulting in reduced lifespan and structural integrity.

Environmental Impact and Sustainability

Bamboo chipboard offers a significantly lower environmental impact compared to traditional particle board due to bamboo's rapid growth rate and carbon sequestration capabilities. Its renewable nature reduces reliance on slower-growing hardwoods, promoting sustainable forestry practices and decreasing deforestation. Furthermore, bamboo chipboard production typically involves fewer toxic adhesives, enhancing indoor air quality and minimizing ecological harm.

Cost Analysis: Bamboo Chipboard vs. Particle Board

Bamboo chipboard generally costs more than particle board due to its sustainable sourcing and superior durability, making it a long-term investment despite higher upfront expenses. Particle board offers a cheaper initial price but tends to require more frequent replacements because of its lower resilience to moisture and weight. Evaluating total lifecycle costs reveals bamboo chipboard's potential for greater cost efficiency in projects prioritizing eco-friendliness and longevity.

Applications in Furniture and Interior Design

Bamboo chipboard offers superior durability and moisture resistance compared to particle board, making it ideal for high-traffic furniture and interior design applications such as cabinetry, shelving, and wall panels. Its natural aesthetics and eco-friendly properties appeal to sustainable design projects, providing a visually warm, textured finish that enhances modern and traditional interiors. Particle board, while more affordable, is commonly used in budget-friendly furniture and interior components where longevity and moisture resistance are less critical.

Moisture Resistance and Longevity

Bamboo chipboard outperforms particle board in moisture resistance due to its dense fiber structure and natural silica content, reducing water absorption and swelling. Its superior durability results in enhanced longevity, making it ideal for humid environments and long-term applications. Particle board, with its lower density and adhesive composition, tends to degrade faster when exposed to moisture, leading to shorter lifespan and structural weakening.

Aesthetic Qualities and Surface Finishes

Bamboo chipboard offers a unique natural grain pattern and a warm, rich aesthetic that enhances interior design with its eco-friendly appeal, while particle board typically features a more uniform, less visually appealing surface. Bamboo chipboard can be finished with clear varnishes or stains that highlight its organic texture, whereas particle board often requires laminate or veneer coatings to improve its appearance. The durability of bamboo chipboard's surface finish generally surpasses particle board, resisting scratches and wear better while maintaining an attractive look over time.

Choosing the Right Board for Your Project

Bamboo chipboard offers superior durability, moisture resistance, and eco-friendliness compared to conventional particle board, making it ideal for projects requiring strength and sustainability. Particle board, typically made from wood scraps and adhesive, is cost-effective but less resilient to wear and humidity, suitable for budget-friendly, low-stress applications. Selecting between bamboo chipboard and particle board depends on project demands for longevity, environmental impact, and budget constraints.

Bamboo chipboard vs particle board Infographic

materialdif.com

materialdif.com