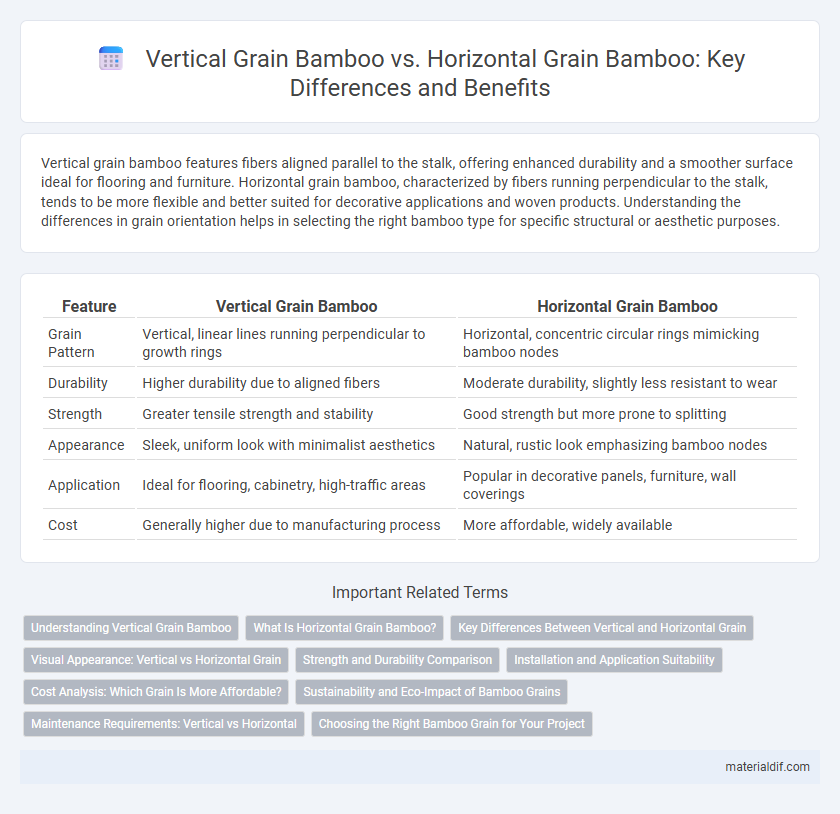

Vertical grain bamboo features fibers aligned parallel to the stalk, offering enhanced durability and a smoother surface ideal for flooring and furniture. Horizontal grain bamboo, characterized by fibers running perpendicular to the stalk, tends to be more flexible and better suited for decorative applications and woven products. Understanding the differences in grain orientation helps in selecting the right bamboo type for specific structural or aesthetic purposes.

Table of Comparison

| Feature | Vertical Grain Bamboo | Horizontal Grain Bamboo |

|---|---|---|

| Grain Pattern | Vertical, linear lines running perpendicular to growth rings | Horizontal, concentric circular rings mimicking bamboo nodes |

| Durability | Higher durability due to aligned fibers | Moderate durability, slightly less resistant to wear |

| Strength | Greater tensile strength and stability | Good strength but more prone to splitting |

| Appearance | Sleek, uniform look with minimalist aesthetics | Natural, rustic look emphasizing bamboo nodes |

| Application | Ideal for flooring, cabinetry, high-traffic areas | Popular in decorative panels, furniture, wall coverings |

| Cost | Generally higher due to manufacturing process | More affordable, widely available |

Understanding Vertical Grain Bamboo

Vertical grain bamboo features fibers aligned parallel to the stalk, providing superior strength and stability compared to horizontal grain bamboo, whose fibers run across the stalk. This alignment enhances resistance to warping, shrinking, and swelling, making vertical grain bamboo ideal for flooring, furniture, and construction. The vertical grain structure also offers a smoother surface and consistent appearance, contributing to its popularity in high-quality bamboo products.

What Is Horizontal Grain Bamboo?

Horizontal grain bamboo features fibers aligned parallel to the ground, creating a distinctive stripe pattern across the surface. This orientation enhances its dimensional stability and resistance to warping compared to vertical grain bamboo. Widely used in flooring and furniture, horizontal grain bamboo offers a unique aesthetic with increased durability and natural texture.

Key Differences Between Vertical and Horizontal Grain

Vertical grain bamboo features fibers aligned parallel to the stalk, resulting in a smoother texture, increased strength, and greater resistance to moisture and warping. Horizontal grain bamboo exhibits fibers arranged in circular rings perpendicular to the stalk, offering a more textured appearance and enhanced flexibility but lower structural strength. These key differences influence their applications, with vertical grain preferred for flooring and furniture requiring durability, while horizontal grain suits decorative uses and lighter construction.

Visual Appearance: Vertical vs Horizontal Grain

Vertical grain bamboo features straight, linear patterns that create a sleek and uniform look, enhancing modern and minimalist designs. Horizontal grain bamboo displays a more segmented and textured appearance with visible nodes and clusters, adding rustic charm and organic depth. Both grain types influence the visual appeal significantly, allowing designers to select based on desired aesthetics and interior style.

Strength and Durability Comparison

Vertical grain bamboo exhibits superior strength and durability due to its aligned fiber structure, allowing it to better resist bending and impact forces. Horizontal grain bamboo, with its crosswise fiber arrangement, tends to have lower tensile strength and is more prone to cracking under stress. Engineers and architects prefer vertical grain bamboo for structural applications requiring maximum load-bearing capacity and longevity.

Installation and Application Suitability

Vertical grain bamboo offers superior dimensional stability and strength, making it ideal for flooring installations where durability and resistance to cupping are critical. Horizontal grain bamboo, with its visible node patterns and slightly softer texture, is better suited for decorative wall panels, furniture, and applications where aesthetic appeal outweighs heavy wear resistance. Choosing between vertical and horizontal grain bamboo depends on the specific installation demands and the desired balance between visual texture and structural performance.

Cost Analysis: Which Grain Is More Affordable?

Vertical grain bamboo typically costs more due to its longer fiber alignment, which enhances durability and strength, making it ideal for high-end flooring and furniture applications. Horizontal grain bamboo, characterized by shorter fibers and a less uniform appearance, is generally more affordable and suitable for budget-conscious projects or decorative uses. Cost analysis shows that vertical grain's premium pricing reflects its superior performance, while horizontal grain offers a cost-effective alternative with aesthetic variability.

Sustainability and Eco-Impact of Bamboo Grains

Vertical grain bamboo offers enhanced durability and strength, resulting in longer-lasting products that reduce the need for frequent replacements and minimize resource consumption. Horizontal grain bamboo, while aesthetically unique, tends to be less dense and more prone to wear, potentially increasing environmental impact through higher waste and processing demands. Choosing vertical grain bamboo supports sustainable practices by optimizing material efficiency and promoting eco-friendly resource management.

Maintenance Requirements: Vertical vs Horizontal

Vertical grain bamboo typically requires less maintenance due to its tighter fiber structure, which enhances durability and resistance to wear and moisture. Horizontal grain bamboo, with its more porous and open fiber arrangement, often demands more frequent sealing and cleaning to prevent damage and extend its lifespan. Selecting vertical grain bamboo can reduce upkeep costs and effort, making it ideal for high-traffic or outdoor applications.

Choosing the Right Bamboo Grain for Your Project

Vertical grain bamboo features fibers aligned parallel to the stalk, offering superior strength and durability, ideal for structural applications and furniture making. Horizontal grain bamboo, with fibers running perpendicular, provides enhanced flexibility and is suited for decorative elements and lightweight projects. Selecting the right bamboo grain depends on balancing strength requirements and aesthetic preferences to optimize performance and appearance.

Vertical grain bamboo vs horizontal grain bamboo Infographic

materialdif.com

materialdif.com