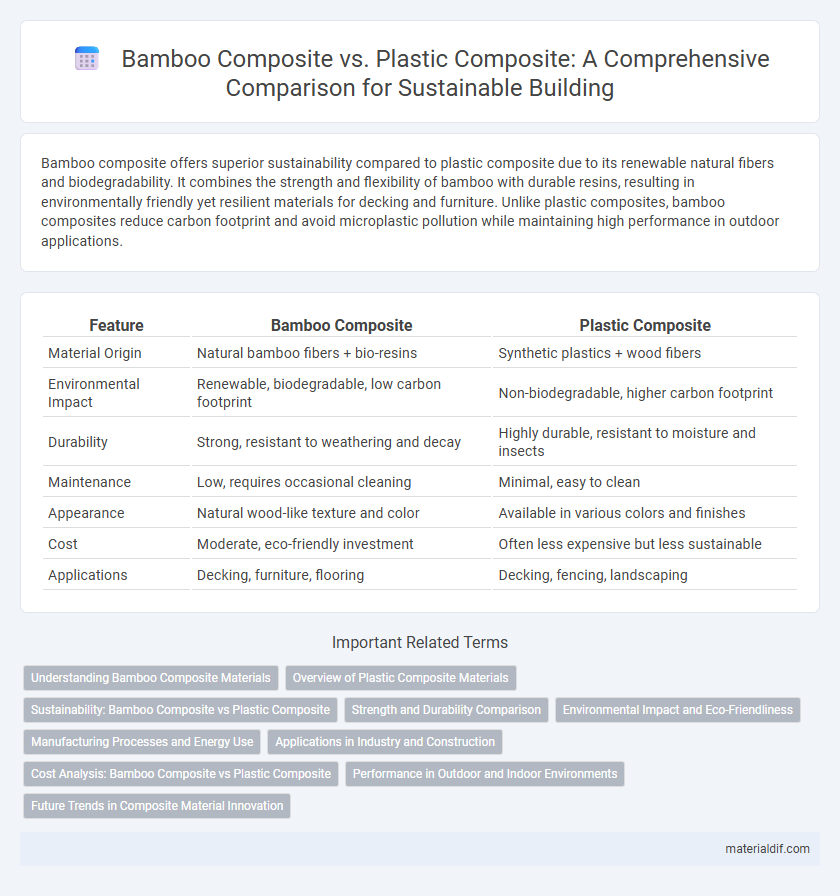

Bamboo composite offers superior sustainability compared to plastic composite due to its renewable natural fibers and biodegradability. It combines the strength and flexibility of bamboo with durable resins, resulting in environmentally friendly yet resilient materials for decking and furniture. Unlike plastic composites, bamboo composites reduce carbon footprint and avoid microplastic pollution while maintaining high performance in outdoor applications.

Table of Comparison

| Feature | Bamboo Composite | Plastic Composite |

|---|---|---|

| Material Origin | Natural bamboo fibers + bio-resins | Synthetic plastics + wood fibers |

| Environmental Impact | Renewable, biodegradable, low carbon footprint | Non-biodegradable, higher carbon footprint |

| Durability | Strong, resistant to weathering and decay | Highly durable, resistant to moisture and insects |

| Maintenance | Low, requires occasional cleaning | Minimal, easy to clean |

| Appearance | Natural wood-like texture and color | Available in various colors and finishes |

| Cost | Moderate, eco-friendly investment | Often less expensive but less sustainable |

| Applications | Decking, furniture, flooring | Decking, fencing, landscaping |

Understanding Bamboo Composite Materials

Bamboo composite materials offer superior biodegradability and natural strength compared to plastic composites, making them an eco-friendly alternative in construction and furniture manufacturing. The inherent tensile strength of bamboo fibers combined with resin binding results in lightweight yet durable panels with excellent moisture resistance. Unlike plastic composites, bamboo composites reduce carbon footprint through renewable sourcing and faster decomposition, aligning with sustainable material innovations.

Overview of Plastic Composite Materials

Plastic composite materials consist primarily of synthetic polymers such as polyethylene, polypropylene, or polyvinyl chloride combined with fillers like wood fibers or mineral additives to enhance durability and weather resistance. These composites offer high moisture resistance, low maintenance requirements, and increased flexibility compared to natural materials, making them popular in construction and outdoor applications. However, their environmental impact and limited biodegradability challenge sustainability compared to bamboo composites.

Sustainability: Bamboo Composite vs Plastic Composite

Bamboo composite materials offer superior sustainability compared to plastic composites due to bamboo's rapid renewability and lower carbon footprint during production. Bamboo composites are biodegradable and contribute to reduced plastic waste accumulation in landfills and oceans. In contrast, plastic composites rely heavily on fossil fuels, generating higher greenhouse gas emissions and persistent environmental pollution.

Strength and Durability Comparison

Bamboo composite exhibits superior strength-to-weight ratio compared to plastic composite, making it a preferred choice for structural applications where resilience is critical. Its natural fibers provide enhanced durability and resistance to cracking, warping, and UV damage, outperforming many plastic composites prone to degradation under prolonged exposure. Bamboo composites also offer better environmental sustainability with similar or greater lifespan, reducing the need for frequent replacement.

Environmental Impact and Eco-Friendliness

Bamboo composite materials have a significantly lower environmental impact compared to plastic composites due to bamboo's rapid renewability and biodegradability, reducing landfill waste and carbon footprint. Bamboo composites require less energy-intensive processing and emit fewer greenhouse gases during production, making them a more sustainable choice for eco-conscious construction and manufacturing. Plastic composites, often derived from fossil fuels, contribute to pollution and persist in ecosystems for centuries, whereas bamboo composites naturally decompose, supporting circular economy principles and minimizing ecological harm.

Manufacturing Processes and Energy Use

Bamboo composite manufacturing typically involves less energy-intensive processes compared to plastic composites, as bamboo fibers require minimal chemical treatment and rely on natural binding agents, reducing overall energy consumption. Plastic composites often necessitate high-temperature extrusion and polymer melting, leading to greater energy use and greenhouse gas emissions. The sustainable harvesting and rapid regrowth of bamboo further enhance its environmental benefits over fossil-fuel-based plastic composites.

Applications in Industry and Construction

Bamboo composite offers superior sustainability and biodegradability compared to plastic composite, making it highly favored in green building projects and industrial applications prioritizing eco-friendly materials. Its natural strength and durability provide excellent structural support, suitable for flooring, panels, and decking used in both residential and commercial construction. Plastic composites, while resistant to moisture and chemicals, often lack the environmental benefits and visual appeal that bamboo composites deliver in modern industrial design.

Cost Analysis: Bamboo Composite vs Plastic Composite

Bamboo composite generally offers a more cost-effective solution compared to plastic composite, with raw material prices typically 20-30% lower due to the abundance and rapid renewability of bamboo. Manufacturing bamboo composites requires less energy and emits fewer greenhouse gases, reducing overall production expenses and environmental costs. Plastic composites, while sometimes cheaper upfront, often involve higher long-term costs related to disposal and environmental impact management.

Performance in Outdoor and Indoor Environments

Bamboo composites demonstrate superior performance in both outdoor and indoor environments due to their natural moisture resistance and durability, outperforming plastic composites that tend to degrade under UV exposure and temperature fluctuations. Bamboo's thermal insulation properties and breathability enhance indoor air quality and comfort, unlike plastic composites, which can trap heat and emit volatile organic compounds (VOCs). The renewable nature of bamboo combined with its structural strength makes it an eco-friendly alternative that maintains stability and aesthetics in varied climatic conditions.

Future Trends in Composite Material Innovation

Bamboo composites are driving future trends in composite material innovation due to their sustainability, biodegradability, and superior mechanical properties compared to plastic composites. Advances in nano-engineering and bio-resin technologies are enhancing the durability and water resistance of bamboo composites, making them viable alternatives in automotive and construction industries. Market projections indicate a growing preference for eco-friendly materials, with bamboo composites expected to capture a significant share driven by increasing environmental regulations and consumer demand.

bamboo composite vs plastic composite Infographic

materialdif.com

materialdif.com