Laminated bamboo is made by gluing flat strips together, resulting in a uniform, stable, and aesthetically consistent material ideal for flooring and furniture. Strand woven bamboo, created by compressing shredded bamboo fibers under high pressure, offers superior hardness and durability, making it highly resistant to wear and ideal for high-traffic areas. Both types provide eco-friendly, sustainable alternatives to traditional hardwood with distinct textures and strengths suited to different applications.

Table of Comparison

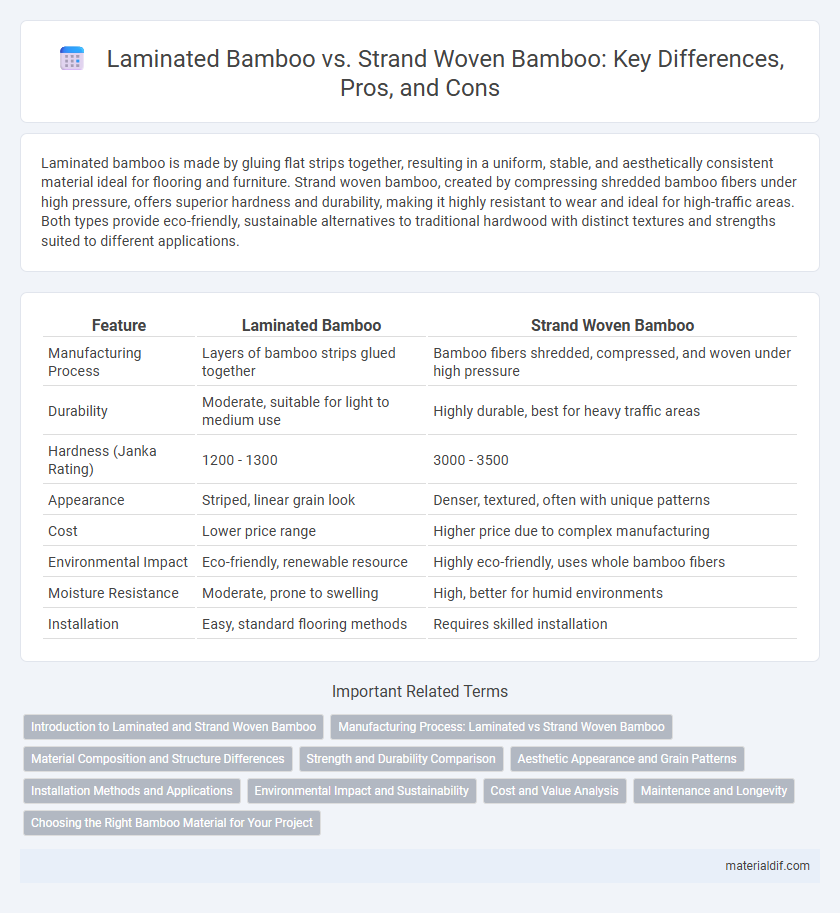

| Feature | Laminated Bamboo | Strand Woven Bamboo |

|---|---|---|

| Manufacturing Process | Layers of bamboo strips glued together | Bamboo fibers shredded, compressed, and woven under high pressure |

| Durability | Moderate, suitable for light to medium use | Highly durable, best for heavy traffic areas |

| Hardness (Janka Rating) | 1200 - 1300 | 3000 - 3500 |

| Appearance | Striped, linear grain look | Denser, textured, often with unique patterns |

| Cost | Lower price range | Higher price due to complex manufacturing |

| Environmental Impact | Eco-friendly, renewable resource | Highly eco-friendly, uses whole bamboo fibers |

| Moisture Resistance | Moderate, prone to swelling | High, better for humid environments |

| Installation | Easy, standard flooring methods | Requires skilled installation |

Introduction to Laminated and Strand Woven Bamboo

Laminated bamboo is created by layering thin strips of bamboo and bonding them with adhesive under heat and pressure, resulting in a durable and stable material commonly used for flooring and furniture. Strand woven bamboo undergoes a more intense process where bamboo fibers are shredded, compressed, and bonded to create an exceptionally dense and hard product, offering superior strength and wear resistance. Both types provide sustainable alternatives to traditional hardwood, with laminated bamboo focusing on aesthetic grain patterns and strand woven bamboo emphasizing durability and hardness.

Manufacturing Process: Laminated vs Strand Woven Bamboo

Laminated bamboo is produced by slicing bamboo stalks into thin strips, which are then glued together in layers under heat and pressure to form durable boards. Strand woven bamboo is created by shredding bamboo fibers into strands, mixing them with adhesive, and compressing under extreme heat and pressure, resulting in a denser, harder material. The manufacturing process of strand woven bamboo yields greater strength and moisture resistance compared to laminated bamboo, making it suitable for high-traffic flooring.

Material Composition and Structure Differences

Laminated bamboo consists of thin bamboo strips bonded together with adhesive to create uniform, flat panels, highlighting its layered structure and consistent texture. Strand woven bamboo is produced by compressing shredded bamboo fibers under extreme heat and pressure, resulting in a denser and harder material with a unique grain pattern. The primary distinction lies in laminated bamboo's strip-based assembly versus strand woven bamboo's fiber-compressed composite, impacting durability and appearance.

Strength and Durability Comparison

Laminated bamboo consists of thin strips glued together, providing moderate strength and resistance suitable for general flooring and furniture applications. Strand woven bamboo is created by compressing bamboo strands under high pressure, resulting in significantly higher density, superior hardness, and increased durability compared to laminated bamboo. This makes strand woven bamboo ideal for high-traffic areas and heavy-use environments due to its enhanced wear resistance and structural integrity.

Aesthetic Appearance and Grain Patterns

Laminated bamboo features a uniform, linear grain pattern that highlights a smooth, consistent aesthetic ideal for modern interior designs. Strand woven bamboo exhibits a denser, variegated grain with a natural, rugged texture resulting from compressed bamboo fibers, adding depth and character. The aesthetic difference is marked by laminated bamboo's sleek, minimal look compared to the strand woven's dynamic, visually intricate surface.

Installation Methods and Applications

Laminated bamboo features layers of bamboo strips glued together, resulting in uniform planks that are easy to install with traditional tongue-and-groove methods suitable for residential flooring and furniture. Strand woven bamboo is created by compressing shredded bamboo fibers under high pressure, producing a denser material ideal for heavy-traffic areas and commercial applications, often requiring professional installation due to its hardness. Both types offer durable flooring options, but laminated bamboo is preferred for DIY projects while strand woven bamboo excels in environments demanding greater impact resistance.

Environmental Impact and Sustainability

Laminated bamboo is produced by layering thin strips of bamboo with adhesive, resulting in moderate environmental impact due to the use of adhesives and energy in the lamination process. Strand woven bamboo, created by compressing shredded bamboo fibers under high pressure and heat, offers greater durability and longevity, reducing the need for frequent replacement and promoting sustainability. Both materials are renewable, but strand woven bamboo's denser structure and higher strength improve its carbon sequestration efficiency, making it a more environmentally favorable option.

Cost and Value Analysis

Laminated bamboo typically costs less than strand woven bamboo due to its simpler manufacturing process, making it a budget-friendly option for flooring and furniture projects. Strand woven bamboo, known for its superior density and durability, offers higher long-term value despite a higher upfront price. The enhanced hardness and resistance to wear in strand woven bamboo justify the investment for high-traffic or heavy-use applications.

Maintenance and Longevity

Laminated bamboo features a smooth surface that simplifies cleaning and requires minimal maintenance, while strand woven bamboo offers superior durability due to its dense composition, making it highly resistant to wear and moisture. Strand woven bamboo's enhanced hardness contributes to greater longevity in high-traffic areas compared to laminated bamboo, which may show signs of wear more quickly under heavy use. Both materials benefit from regular cleaning and occasional resealing to extend their lifespan, but strand woven bamboo generally demands less frequent upkeep due to its robust structure.

Choosing the Right Bamboo Material for Your Project

Laminated bamboo offers a smooth, uniform appearance and is ideal for projects requiring consistent texture and moderate durability, making it a top choice for furniture and cabinetry. Strand woven bamboo undergoes an intense compression process, resulting in superior hardness and resistance to wear, perfect for high-traffic flooring and heavy-use surfaces. Evaluating project requirements such as durability, aesthetics, and budget will help determine whether laminated or strand woven bamboo best suits your specific application.

Laminated bamboo vs strand woven bamboo Infographic

materialdif.com

materialdif.com