Mechanically processed bamboo retains its natural fibers and strength by using physical methods like crushing and rolling, making it more environmentally friendly and durable. Chemically processed bamboo undergoes treatments with harsh chemicals to break down fibers, which can weaken the material and pose environmental hazards due to chemical waste. Choosing mechanically processed bamboo supports sustainability and produces stronger, eco-friendly products.

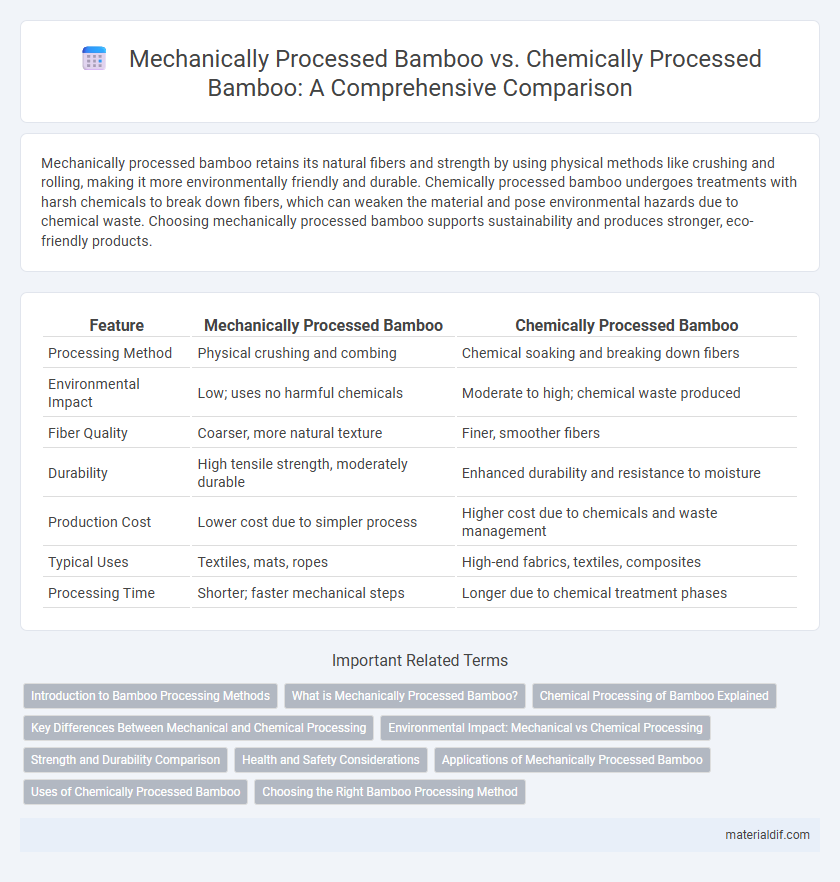

Table of Comparison

| Feature | Mechanically Processed Bamboo | Chemically Processed Bamboo |

|---|---|---|

| Processing Method | Physical crushing and combing | Chemical soaking and breaking down fibers |

| Environmental Impact | Low; uses no harmful chemicals | Moderate to high; chemical waste produced |

| Fiber Quality | Coarser, more natural texture | Finer, smoother fibers |

| Durability | High tensile strength, moderately durable | Enhanced durability and resistance to moisture |

| Production Cost | Lower cost due to simpler process | Higher cost due to chemicals and waste management |

| Typical Uses | Textiles, mats, ropes | High-end fabrics, textiles, composites |

| Processing Time | Shorter; faster mechanical steps | Longer due to chemical treatment phases |

Introduction to Bamboo Processing Methods

Mechanically processed bamboo retains its natural fibers by physically crushing and combing the stalks, resulting in stronger, eco-friendly bamboo fiber mats ideal for textiles and construction. Chemically processed bamboo uses solvents and chemicals to break down bamboo into viscose or rayon, producing softer fabrics but involving environmentally harmful compounds like sodium hydroxide and carbon disulfide. Choosing between these processing methods impacts the sustainability and durability of bamboo products in applications ranging from flooring to apparel.

What is Mechanically Processed Bamboo?

Mechanically processed bamboo involves stripping, crushing, and combing the bamboo fibers without the use of chemicals, preserving the natural integrity and strength of the fibers. This eco-friendly method enhances durability and maintains the bamboo's inherent antimicrobial properties, making it ideal for textiles and sustainable construction materials. Unlike chemically processed bamboo, mechanical treatment avoids toxic residues, promoting sustainable production and healthier end products.

Chemical Processing of Bamboo Explained

Chemical processing of bamboo involves treating raw bamboo with chemicals such as sodium hydroxide and sodium sulfide to break down lignin and hemicellulose, facilitating the extraction of cellulose fibers. This method enhances the durability, flexibility, and pest resistance of bamboo products, making them suitable for textiles, composites, and engineered materials. Compared to mechanical processing, chemical treatment yields finer, stronger fibers but requires careful management of chemical waste to minimize environmental impact.

Key Differences Between Mechanical and Chemical Processing

Mechanical processing of bamboo involves physically crushing and grinding bamboo fibers to create products like laminated boards and textiles, preserving most of the bamboo's natural components and ensuring eco-friendliness. Chemical processing uses solvents and chemical treatments, such as alkali or bleaching agents, to break down lignin and hemicellulose for producing bamboo viscose or rayon, resulting in a softer, more pliable material but with higher environmental impact. Key differences include environmental sustainability, fiber strength retention, and the complexity of processing methods, where mechanical processing maintains fiber strength with minimal waste, while chemical processing yields finer fibers at the cost of chemical usage and potential pollution.

Environmental Impact: Mechanical vs Chemical Processing

Mechanical processing of bamboo involves physical methods like crushing and rolling, which consume less energy and avoid harmful chemicals, resulting in a significantly lower environmental impact compared to chemical processing. Chemical processing uses substances such as sodium hydroxide and carbon disulfide, leading to toxic wastewater and air pollution that contribute to ecosystem degradation and health risks. Mechanical processing supports sustainable bamboo production by preserving natural fibers without releasing hazardous byproducts, making it a preferred eco-friendly option.

Strength and Durability Comparison

Mechanically processed bamboo retains its natural fiber structure, resulting in superior tensile strength and increased durability compared to chemically processed bamboo, which often undergoes treatments that can weaken the fibers over time. Mechanical processing methods, such as splitting and polishing, maintain the integrity of cellulose and lignin, essential for structural resilience. In contrast, chemical processing may introduce substances that degrade bamboo's strength, reducing its lifespan, especially in construction and outdoor applications.

Health and Safety Considerations

Mechanically processed bamboo retains its natural fibers without the use of harmful chemicals, reducing exposure to toxic substances and promoting safer indoor air quality. Chemically processed bamboo often involves treatments with formaldehyde and other volatile organic compounds (VOCs), which can pose respiratory risks and skin irritation. Ensuring proper ventilation and using low-VOC treatments can mitigate health hazards associated with chemically treated bamboo products.

Applications of Mechanically Processed Bamboo

Mechanically processed bamboo retains its natural fibers and structural integrity, making it ideal for construction materials, furniture, and eco-friendly packaging solutions. This method enhances bamboo's mechanical strength and flexibility without introducing harmful chemicals, supporting sustainable applications in flooring, panels, and textile fibers. Its use in load-bearing structures and biodegradable products underscores the environmental and functional advantages over chemically treated alternatives.

Uses of Chemically Processed Bamboo

Chemically processed bamboo is primarily used in the production of bamboo pulp for paper, textiles, and viscose fiber manufacturing, exploiting its cellulose-rich structure. This method involves breaking down bamboo fibers with chemicals to create smooth, durable fabrics and biodegradable materials ideal for eco-friendly fashion and home textiles. Chemically treated bamboo also finds applications in producing composites and bioenergy due to its enhanced versatility and improved fiber quality.

Choosing the Right Bamboo Processing Method

Mechanically processed bamboo retains its natural strength and eco-friendliness by using physical techniques such as stripping, splitting, and sanding, resulting in durable, sustainable products ideal for construction and textiles. Chemically processed bamboo involves treatments with solvents and bleaching agents to enhance softness and uniformity, often used in bamboo viscose fabric production but raising environmental concerns due to chemical waste. Selecting the right bamboo processing method depends on the intended application, desired product characteristics, and environmental impact preferences.

mechanically processed bamboo vs chemically processed bamboo Infographic

materialdif.com

materialdif.com