Bamboo viscose is produced using a chemical-intensive process that breaks down bamboo cellulose with toxic solvents, resulting in a softer but less eco-friendly fabric. Bamboo lyocell utilizes a closed-loop system that recycles solvents, making it a more sustainable and environmentally responsible choice. Both fabrics offer breathability and comfort, but bamboo lyocell provides better durability and reduced environmental impact compared to bamboo viscose.

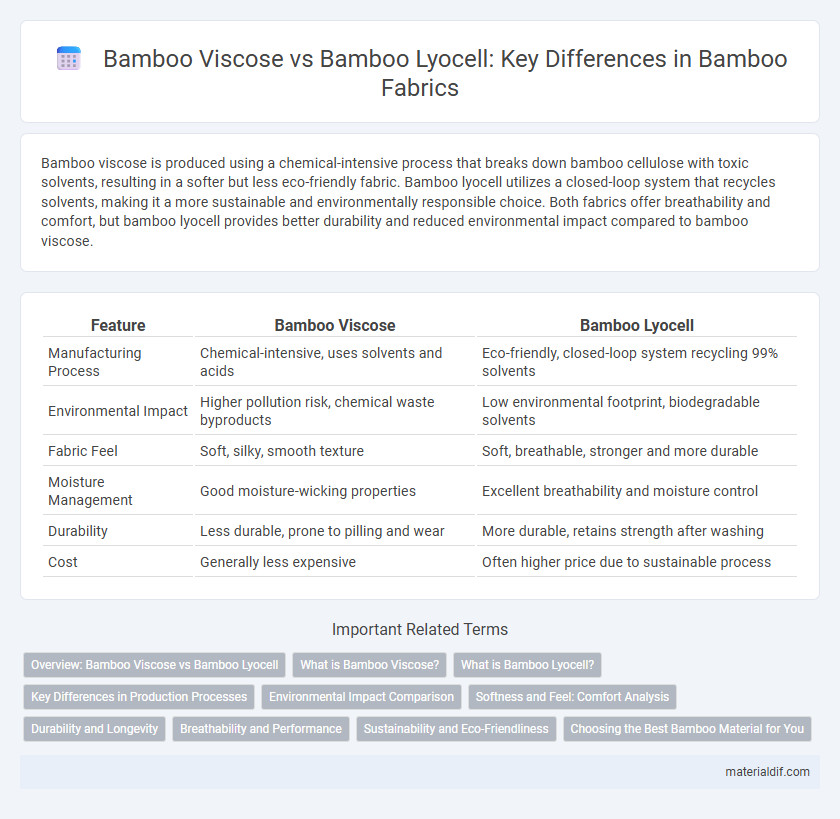

Table of Comparison

| Feature | Bamboo Viscose | Bamboo Lyocell |

|---|---|---|

| Manufacturing Process | Chemical-intensive, uses solvents and acids | Eco-friendly, closed-loop system recycling 99% solvents |

| Environmental Impact | Higher pollution risk, chemical waste byproducts | Low environmental footprint, biodegradable solvents |

| Fabric Feel | Soft, silky, smooth texture | Soft, breathable, stronger and more durable |

| Moisture Management | Good moisture-wicking properties | Excellent breathability and moisture control |

| Durability | Less durable, prone to pilling and wear | More durable, retains strength after washing |

| Cost | Generally less expensive | Often higher price due to sustainable process |

Overview: Bamboo Viscose vs Bamboo Lyocell

Bamboo viscose and bamboo lyocell are two popular types of sustainable fabric derived from bamboo cellulose, differing mainly in their manufacturing process and environmental impact. Bamboo viscose uses a chemical-intensive method involving sodium hydroxide and carbon disulfide, resulting in a softer texture but higher ecological footprint. Bamboo lyocell employs a closed-loop process with non-toxic solvents like N-methylmorpholine N-oxide, offering enhanced durability, breathability, and significantly better sustainability credentials.

What is Bamboo Viscose?

Bamboo viscose is a type of regenerated cellulose fiber made by chemically processing bamboo pulp into a soft, breathable fabric widely used in textiles. This process involves dissolving bamboo cellulose with chemicals like sodium hydroxide and carbon disulfide to produce viscose rayon fibers, which offer excellent moisture-wicking and antibacterial properties. Bamboo viscose is valued for its silky texture, durability, and eco-friendly appeal compared to conventional synthetics.

What is Bamboo Lyocell?

Bamboo lyocell is a sustainable fabric made from bamboo pulp using a closed-loop solvent spinning process that minimizes environmental impact. Compared to bamboo viscose, lyocell fibers retain more strength and softness while being produced with fewer harmful chemicals. This eco-friendly production method makes bamboo lyocell a preferred choice for durable, breathable, and biodegradable textiles.

Key Differences in Production Processes

Bamboo viscose is produced through a chemical-intensive process involving the use of carbon disulfide to convert bamboo cellulose into a viscous solution, which is then spun into fibers, resulting in environmental concerns due to toxic emissions. Bamboo lyocell uses a closed-loop solvent spinning method with non-toxic organic solvents, allowing most chemicals to be recycled and minimizing ecological impact. The key difference lies in bamboo lyocell's eco-friendly production system compared to the more pollutive, chemically harsh viscose process.

Environmental Impact Comparison

Bamboo viscose production involves chemical-intensive processes that generate significant pollution and waste, negatively impacting ecosystems. Bamboo lyocell uses a closed-loop system where solvents are recycled, reducing environmental toxins and water consumption. This sustainable manufacturing approach makes bamboo lyocell a more eco-friendly choice compared to traditional bamboo viscose fibers.

Softness and Feel: Comfort Analysis

Bamboo viscose offers a smooth, silky texture that provides a luxurious softness ideal for sensitive skin, while bamboo lyocell is known for its breathable, moisture-wicking properties and a slightly more structured feel. Bamboo lyocell tends to maintain durability and shape better over time, contributing to long-lasting comfort through enhanced airflow and reduced heat retention. Both fabrics deliver superior comfort compared to conventional cotton, with bamboo viscose prioritizing immediate softness and bamboo lyocell emphasizing sustained breathability and wearability.

Durability and Longevity

Bamboo viscose, produced through a chemical-intensive process, tends to have lower durability and may degrade faster with frequent washing compared to bamboo lyocell. Bamboo lyocell is made using a more eco-friendly closed-loop process, resulting in stronger fibers that enhance fabric longevity and resistance to wear. Choosing bamboo lyocell offers superior durability for sustainable textiles and long-lasting apparel.

Breathability and Performance

Bamboo viscose offers moderate breathability but often retains more moisture, making it less ideal for high-performance athletic wear. Bamboo lyocell excels in breathability due to its advanced moisture-wicking properties and enhanced durability, providing superior comfort during intense physical activities. Its eco-friendly closed-loop production process also contributes to better fabric performance and sustainability compared to bamboo viscose.

Sustainability and Eco-Friendliness

Bamboo lyocell is considered more sustainable and eco-friendly than bamboo viscose due to its closed-loop manufacturing process that recycles water and solvents, minimizing environmental impact. Bamboo viscose production involves chemical-heavy methods that generate significant pollution and waste, raising concerns over its ecological footprint. Opting for bamboo lyocell supports reduced chemical use, lower energy consumption, and better biodegradability, aligning with eco-conscious textile choices.

Choosing the Best Bamboo Material for You

Bamboo viscose and bamboo lyocell are two popular bamboo fabrics with distinct production methods impacting their sustainability and comfort. Bamboo lyocell is manufactured using a closed-loop process that recycles solvents, making it more eco-friendly and less chemically intensive than bamboo viscose, which uses harsher chemicals in its production. When choosing the best bamboo material, consider bamboo lyocell for its durability, breathability, and lower environmental impact, while bamboo viscose offers softness and affordability but may come with a higher ecological footprint.

bamboo viscose vs bamboo lyocell Infographic

materialdif.com

materialdif.com