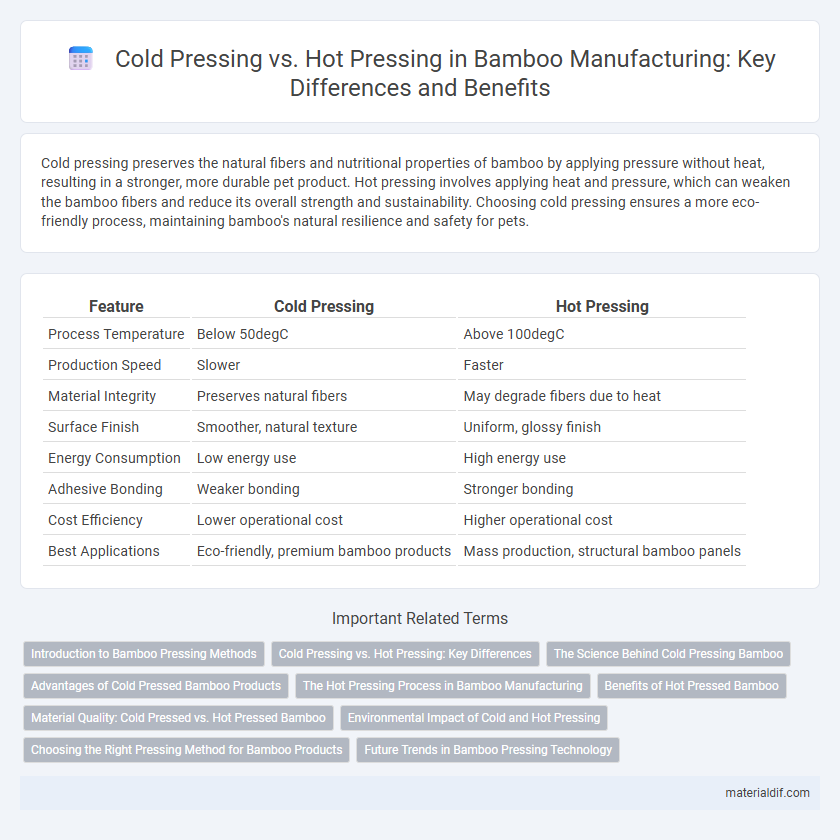

Cold pressing preserves the natural fibers and nutritional properties of bamboo by applying pressure without heat, resulting in a stronger, more durable pet product. Hot pressing involves applying heat and pressure, which can weaken the bamboo fibers and reduce its overall strength and sustainability. Choosing cold pressing ensures a more eco-friendly process, maintaining bamboo's natural resilience and safety for pets.

Table of Comparison

| Feature | Cold Pressing | Hot Pressing |

|---|---|---|

| Process Temperature | Below 50degC | Above 100degC |

| Production Speed | Slower | Faster |

| Material Integrity | Preserves natural fibers | May degrade fibers due to heat |

| Surface Finish | Smoother, natural texture | Uniform, glossy finish |

| Energy Consumption | Low energy use | High energy use |

| Adhesive Bonding | Weaker bonding | Stronger bonding |

| Cost Efficiency | Lower operational cost | Higher operational cost |

| Best Applications | Eco-friendly, premium bamboo products | Mass production, structural bamboo panels |

Introduction to Bamboo Pressing Methods

Cold pressing bamboo involves applying pressure at low temperatures, preserving the natural fibers' strength and flexibility, which results in a durable and eco-friendly product. Hot pressing uses heat and pressure simultaneously, accelerating the curing process and producing a denser, more rigid material ideal for structural applications. Selecting the appropriate pressing method impacts the bamboo's mechanical properties, moisture resistance, and overall performance in construction or manufacturing.

Cold Pressing vs. Hot Pressing: Key Differences

Cold pressing bamboo preserves its natural fibers and enhances durability by applying pressure without heat, resulting in stronger, more flexible panels ideal for high-quality flooring and furniture. Hot pressing involves compressing bamboo under high temperature and pressure, which accelerates production and enhances surface smoothness but can reduce fiber strength and increase brittleness. The choice between cold pressing and hot pressing depends on balancing product strength, flexibility, and manufacturing efficiency in bamboo processing.

The Science Behind Cold Pressing Bamboo

Cold pressing bamboo retains more lignin and cellulose structure by applying low heat and high pressure, preserving its natural strength and flexibility. This method minimizes the breakdown of fibers and prevents degradation of bamboo's organic compounds, resulting in enhanced durability and eco-friendly material properties. Research shows cold pressing maintains higher tensile strength and moisture resistance compared to hot pressing, making it ideal for sustainable bamboo products.

Advantages of Cold Pressed Bamboo Products

Cold pressed bamboo products retain higher structural integrity by preserving natural fibers and nutrients, resulting in enhanced durability and sustainability. This method minimizes exposure to heat, reducing the risk of warping, cracking, and chemical degradation commonly seen in hot pressing. As a result, cold pressed bamboo offers superior moisture resistance, increased strength, and a more eco-friendly manufacturing process.

The Hot Pressing Process in Bamboo Manufacturing

The hot pressing process in bamboo manufacturing involves applying high temperature and pressure to bamboo fibers, resulting in enhanced density, strength, and dimensional stability. This method improves the bonding of adhesive resins, yielding durable and moisture-resistant bamboo panels ideal for flooring and furniture. Hot pressing also accelerates production time and produces a smoother surface finish compared to cold pressing techniques.

Benefits of Hot Pressed Bamboo

Hot pressed bamboo offers superior density and strength compared to cold pressed bamboo, resulting in enhanced durability and resistance to wear. The high heat and pressure during hot pressing improve the bamboo's moisture resistance, reducing the risk of warping and swelling in humid environments. This manufacturing method also allows for a smoother, more uniform finish, making hot pressed bamboo an ideal choice for flooring and high-traffic applications.

Material Quality: Cold Pressed vs. Hot Pressed Bamboo

Cold pressing bamboo preserves the natural fibers and nutrients by applying pressure at lower temperatures, resulting in higher material quality with enhanced durability and moisture resistance. Hot pressing exposes bamboo to elevated heat and pressure, which can weaken fiber integrity and increase the risk of brittleness, potentially compromising longevity. Manufacturers seeking superior strength and resistance typically prefer cold pressed bamboo for premium construction and eco-friendly applications.

Environmental Impact of Cold and Hot Pressing

Cold pressing bamboo involves minimal energy consumption and preserves natural fibers, resulting in a lower carbon footprint compared to hot pressing, which requires high temperatures and substantial energy input. Hot pressing emits more greenhouse gases due to the use of heat and often involves adhesives or chemicals that can contribute to environmental pollution. Choosing cold pressing supports sustainable bamboo manufacturing by reducing emissions and maintaining eco-friendly production processes.

Choosing the Right Pressing Method for Bamboo Products

Cold pressing bamboo preserves its natural strength and flexibility by maintaining lower temperatures during manufacturing, resulting in higher durability and less risk of fiber damage. Hot pressing accelerates the curing process through elevated heat and pressure, improving production speed but potentially reducing bamboo's resilience due to fiber softening. Selecting the appropriate pressing method depends on the desired balance between structural integrity, production efficiency, and the specific application requirements of the bamboo product.

Future Trends in Bamboo Pressing Technology

Cold pressing in bamboo manufacturing preserves natural fibers and enhances durability by maintaining lignin structure, leading to eco-friendly, high-strength materials. Hot pressing accelerates production with higher temperatures and pressure, enabling composite materials with improved moisture resistance and uniform density. Future trends focus on hybrid pressing technologies integrating precise temperature control and pressure modulation to optimize mechanical properties while reducing energy consumption and environmental impact.

cold pressing vs hot pressing (bamboo manufacturing) Infographic

materialdif.com

materialdif.com