Bamboo chips offer a softer, more absorbent bedding option for pets, making them ideal for small animals that require gentle cushioning. Bamboo strips are firmer and more durable, providing long-lasting support and better odor control for larger pets or those that prefer a more solid surface. Choosing between bamboo chips and strips depends on your pet's comfort needs and living environment.

Table of Comparison

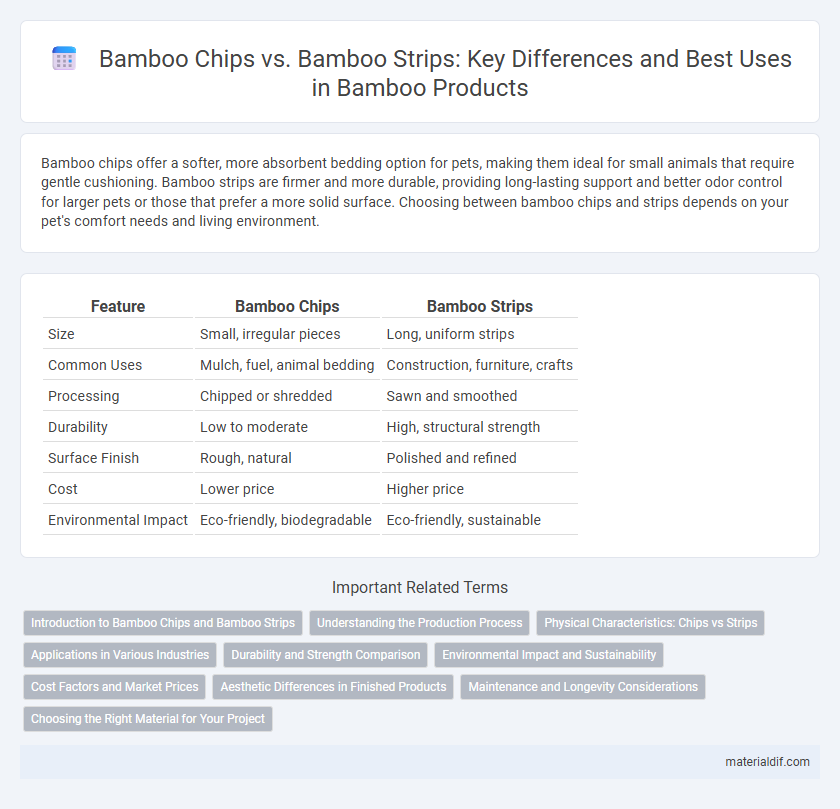

| Feature | Bamboo Chips | Bamboo Strips |

|---|---|---|

| Size | Small, irregular pieces | Long, uniform strips |

| Common Uses | Mulch, fuel, animal bedding | Construction, furniture, crafts |

| Processing | Chipped or shredded | Sawn and smoothed |

| Durability | Low to moderate | High, structural strength |

| Surface Finish | Rough, natural | Polished and refined |

| Cost | Lower price | Higher price |

| Environmental Impact | Eco-friendly, biodegradable | Eco-friendly, sustainable |

Introduction to Bamboo Chips and Bamboo Strips

Bamboo chips are small, uniformly sized pieces derived from bamboo culms, primarily used in smoking, grilling, and as raw material for activated carbon production. Bamboo strips are thin, elongated slices cut from mature bamboo poles, commonly employed in furniture making, flooring, and weaving crafts. Both forms highlight bamboo's versatility, with chips suited for combustion and strips optimized for structural and decorative applications.

Understanding the Production Process

Bamboo chips are produced by crushing whole bamboo poles into small, irregular pieces, making them ideal for pulping and biomass applications. Bamboo strips are created by slicing bamboo poles into long, uniform pieces, commonly used in flooring, furniture, and construction. Understanding these production methods highlights how mechanical processing affects the material's size, shape, and end-use suitability.

Physical Characteristics: Chips vs Strips

Bamboo chips are small, irregular pieces with varied shapes and rough edges, ideal for mulch and fuel due to their high surface area and quick drying properties. Bamboo strips are long, thin, and uniform in thickness, offering structural strength and flexibility, making them suitable for weaving and construction materials. The physical differences in size, shape, and texture directly influence their specific uses and processing methods.

Applications in Various Industries

Bamboo chips serve as a sustainable raw material for producing activated carbon, biofuels, and pulp in the paper industry, offering high surface area and efficient processing. Bamboo strips are preferred in construction, furniture, and handicrafts due to their strength, flexibility, and aesthetic appeal, providing durable and eco-friendly alternatives to traditional wood. Both forms support environmental sustainability across industries by reducing deforestation and promoting renewable resource usage.

Durability and Strength Comparison

Bamboo chips offer moderate strength and are mainly used in composite materials, providing decent durability but limited structural support. Bamboo strips, on the other hand, exhibit superior strength and enhanced durability, making them ideal for construction, furniture, and flooring applications. The dense fiber arrangement in bamboo strips grants greater load-bearing capacity compared to the fragmented nature of bamboo chips.

Environmental Impact and Sustainability

Bamboo chips generate less waste and require minimal processing compared to bamboo strips, resulting in lower energy consumption and carbon emissions during production. Bamboo strips often demand chemical treatments and intensive labor, which can increase environmental footprints and reduce overall sustainability. Utilizing bamboo chips supports more sustainable practices by maximizing raw material usage and promoting eco-friendly manufacturing processes.

Cost Factors and Market Prices

Bamboo chips generally cost less than bamboo strips due to lower processing requirements and their primary use in biomass fuel or raw material for paper production. Bamboo strips, often used in furniture and handicrafts, incur higher market prices because of the labor-intensive processing and quality standards necessary for durable and aesthetically pleasing products. Variations in regional availability, processing technology, and demand for finished goods significantly influence the cost factors and market prices between bamboo chips and strips.

Aesthetic Differences in Finished Products

Bamboo chips produce a more textured and rustic appearance in finished products due to their uneven, organic shapes, enhancing natural aesthetics. Bamboo strips offer a sleek and uniform look with smooth, consistent surfaces ideal for modern and minimalist designs. The choice between chips and strips significantly influences the visual appeal, where chips emphasize rugged charm and strips convey refined elegance.

Maintenance and Longevity Considerations

Bamboo chips require more frequent replacement due to faster deterioration from exposure to weather and moisture, impacting overall maintenance efforts. Bamboo strips, being denser and thicker, offer superior durability and longer lifespan, reducing the need for constant upkeep. Choosing bamboo strips enhances longevity and minimizes maintenance costs over time.

Choosing the Right Material for Your Project

Bamboo chips offer excellent flexibility and natural texture, making them ideal for decorative crafts and mulch applications, while bamboo strips provide superior strength and uniformity suitable for furniture, flooring, and structural projects. The choice depends on the required durability and finish, with bamboo strips delivering consistent dimensions and load-bearing capacity, and chips enhancing aesthetic appeal and moisture management. Selecting the right bamboo form ensures optimal performance, longevity, and visual impact tailored to specific project needs.

Bamboo chips vs bamboo strips Infographic

materialdif.com

materialdif.com