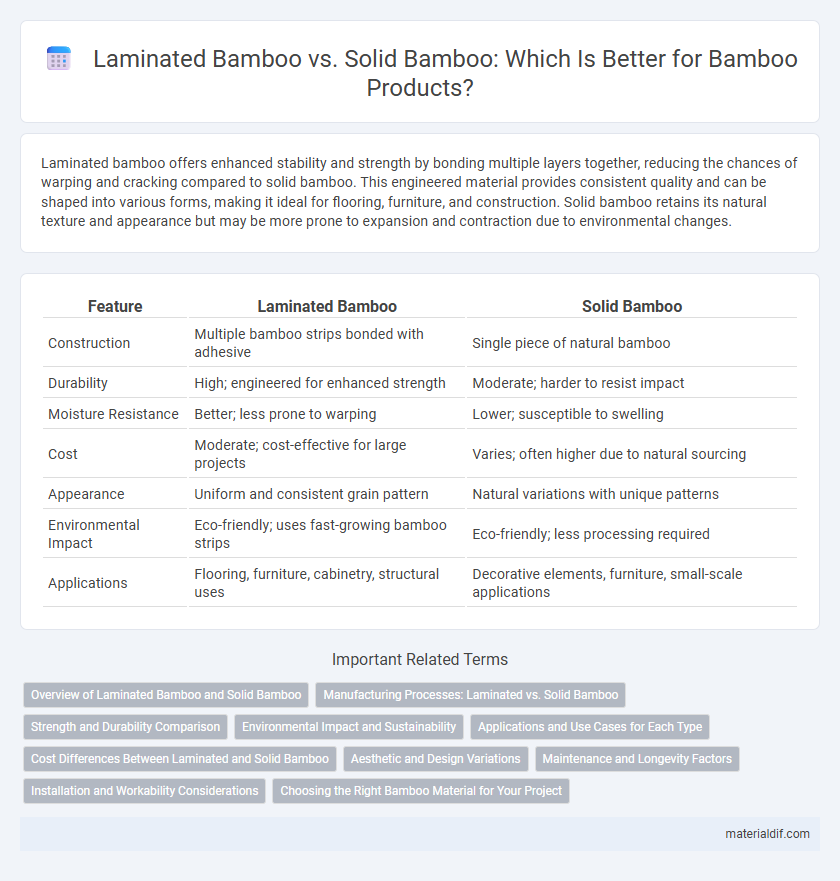

Laminated bamboo offers enhanced stability and strength by bonding multiple layers together, reducing the chances of warping and cracking compared to solid bamboo. This engineered material provides consistent quality and can be shaped into various forms, making it ideal for flooring, furniture, and construction. Solid bamboo retains its natural texture and appearance but may be more prone to expansion and contraction due to environmental changes.

Table of Comparison

| Feature | Laminated Bamboo | Solid Bamboo |

|---|---|---|

| Construction | Multiple bamboo strips bonded with adhesive | Single piece of natural bamboo |

| Durability | High; engineered for enhanced strength | Moderate; harder to resist impact |

| Moisture Resistance | Better; less prone to warping | Lower; susceptible to swelling |

| Cost | Moderate; cost-effective for large projects | Varies; often higher due to natural sourcing |

| Appearance | Uniform and consistent grain pattern | Natural variations with unique patterns |

| Environmental Impact | Eco-friendly; uses fast-growing bamboo strips | Eco-friendly; less processing required |

| Applications | Flooring, furniture, cabinetry, structural uses | Decorative elements, furniture, small-scale applications |

Overview of Laminated Bamboo and Solid Bamboo

Laminated bamboo is manufactured by bonding multiple layers of bamboo veneers together with strong adhesives, resulting in enhanced durability, stability, and resistance to warping. Solid bamboo is crafted from a single piece of bamboo culm, offering natural aesthetics but less structural strength compared to laminated bamboo. Laminated bamboo is preferred for applications requiring dimensional stability and uniformity, while solid bamboo is favored for its organic texture and simplicity.

Manufacturing Processes: Laminated vs. Solid Bamboo

Laminated bamboo is produced by bonding multiple thin strips of bamboo with adhesives under heat and pressure, resulting in a dense, uniform material that enhances strength and stability. Solid bamboo is crafted by cutting and shaping a single bamboo stalk, preserving its natural grain but with greater variability in density and potential for splitting. These manufacturing differences affect durability, flexibility, and application suitability in construction and furniture design.

Strength and Durability Comparison

Laminated bamboo consists of multiple layers of bamboo strips bonded together, enhancing its strength and resistance to warping compared to solid bamboo. Solid bamboo, while naturally strong, may be more prone to cracking and splitting under heavy stress or environmental changes. Laminated bamboo's engineered construction provides superior durability, making it a preferred choice for flooring and structural applications requiring long-lasting performance.

Environmental Impact and Sustainability

Laminated bamboo typically has a lower environmental impact than solid bamboo due to its efficient use of bamboo strips, reducing waste by utilizing smaller, fast-growing bamboo culms. Solid bamboo often requires harvesting larger, older stalks, which can slow regrowth and impact biodiversity more than laminated products. Both types promote sustainability compared to traditional hardwoods, but laminated bamboo's engineered production maximizes resource efficiency and reduces deforestation risks.

Applications and Use Cases for Each Type

Laminated bamboo offers enhanced dimensional stability and strength, making it ideal for flooring, furniture, and cabinetry where durability and resistance to warping are crucial. Solid bamboo, prized for its natural look and sustainability, is commonly used in traditional construction, wall paneling, and smaller craft projects. Each type serves distinct applications: laminated bamboo excels in high-traffic environments, while solid bamboo fits decorative and structural uses requiring natural material aesthetics.

Cost Differences Between Laminated and Solid Bamboo

Laminated bamboo typically costs less than solid bamboo due to its manufacturing process, which involves gluing multiple bamboo layers, enhancing material usage efficiency and reducing raw material waste. Solid bamboo, harvested as whole stalks, demands more labor and raw resources, driving up its price. Budget-conscious consumers often prefer laminated bamboo flooring or furniture for its affordability combined with durability.

Aesthetic and Design Variations

Laminated bamboo offers enhanced design flexibility, allowing for intricate patterns and varied color tones due to the layering process, which enhances aesthetic appeal in modern interiors. Solid bamboo provides a more natural and uniform appearance, showcasing the bamboo's original grain and texture, favored for traditional and rustic designs. Both materials contribute unique visual characteristics, with laminated bamboo excelling in customizable styles while solid bamboo emphasizes organic beauty.

Maintenance and Longevity Factors

Laminated bamboo features multiple layers bonded together, enhancing dimensional stability and resistance to warping, which reduces maintenance frequency compared to solid bamboo. Solid bamboo, while offering a more natural aesthetic, requires regular sealing and moisture control to prevent cracking and insect damage. Proper maintenance, including periodic refinishing and humidity regulation, significantly extends the longevity of both laminated and solid bamboo flooring.

Installation and Workability Considerations

Laminated bamboo offers superior stability and uniformity, making it easier to install with fewer gaps and less risk of warping compared to solid bamboo. Solid bamboo requires precise acclimatization and careful handling during installation due to its natural variations and susceptibility to expansion or contraction. Both materials benefit from professional tools, but laminated bamboo generally allows for faster, more straightforward workability in flooring and furniture applications.

Choosing the Right Bamboo Material for Your Project

Laminated bamboo offers enhanced strength and stability by bonding multiple bamboo strips under high pressure, making it ideal for structural applications and furniture requiring durability. Solid bamboo provides a natural aesthetic with a uniform grain pattern, perfect for projects emphasizing organic texture and appearance. Selecting between laminated and solid bamboo depends on balancing factors like load-bearing needs, design preference, and environmental exposure.

laminated bamboo vs solid bamboo Infographic

materialdif.com

materialdif.com