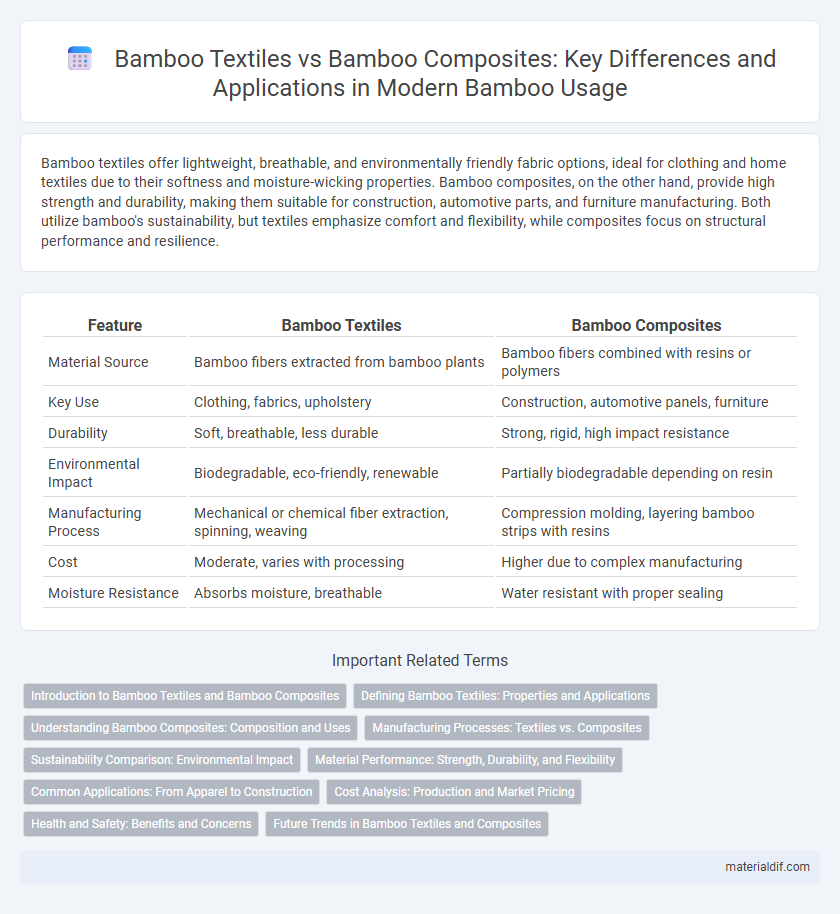

Bamboo textiles offer lightweight, breathable, and environmentally friendly fabric options, ideal for clothing and home textiles due to their softness and moisture-wicking properties. Bamboo composites, on the other hand, provide high strength and durability, making them suitable for construction, automotive parts, and furniture manufacturing. Both utilize bamboo's sustainability, but textiles emphasize comfort and flexibility, while composites focus on structural performance and resilience.

Table of Comparison

| Feature | Bamboo Textiles | Bamboo Composites |

|---|---|---|

| Material Source | Bamboo fibers extracted from bamboo plants | Bamboo fibers combined with resins or polymers |

| Key Use | Clothing, fabrics, upholstery | Construction, automotive panels, furniture |

| Durability | Soft, breathable, less durable | Strong, rigid, high impact resistance |

| Environmental Impact | Biodegradable, eco-friendly, renewable | Partially biodegradable depending on resin |

| Manufacturing Process | Mechanical or chemical fiber extraction, spinning, weaving | Compression molding, layering bamboo strips with resins |

| Cost | Moderate, varies with processing | Higher due to complex manufacturing |

| Moisture Resistance | Absorbs moisture, breathable | Water resistant with proper sealing |

Introduction to Bamboo Textiles and Bamboo Composites

Bamboo textiles are produced by processing bamboo fibers into soft, breathable fabrics ideal for clothing and home textiles, known for their natural antibacterial and moisture-wicking properties. Bamboo composites, on the other hand, combine bamboo fibers with resins or other materials to create strong, durable panels and structural components used in construction, automotive, and furniture industries. Both bamboo textiles and composites leverage bamboo's rapid growth and sustainability, but serve distinct functional and industrial purposes.

Defining Bamboo Textiles: Properties and Applications

Bamboo textiles are derived primarily from bamboo fibers processed into soft, breathable fabrics known for their natural antibacterial and moisture-wicking properties, making them ideal for clothing and home textiles. Unlike bamboo composites, which combine bamboo fibers with resins or polymers for enhanced structural strength in construction and industrial applications, bamboo textiles prioritize comfort and sustainability. The eco-friendly characteristics and biodegradability of bamboo textiles drive their increasing use in fashion, bedding, and activewear markets.

Understanding Bamboo Composites: Composition and Uses

Bamboo composites are engineered materials made by combining bamboo fibers with resins or polymers to enhance strength, durability, and versatility. These composites are widely used in construction, furniture, automotive parts, and sports equipment due to their lightweight and high tensile strength. Unlike bamboo textiles, which focus on soft, breathable fabric production, bamboo composites prioritize structural applications where mechanical performance is critical.

Manufacturing Processes: Textiles vs. Composites

Bamboo textiles are produced by mechanically shredding bamboo culms, then chemically treating or enzymatically breaking down fibers before spinning them into yarn, emphasizing softness and breathability. Bamboo composites involve processing bamboo fibers or particles with resins or polymers through compression molding or extrusion, prioritizing strength and structural integrity. The manufacturing processes differ significantly: textiles focus on fiber extraction and fabric formation, while composites emphasize fiber reinforcement and material bonding for durability.

Sustainability Comparison: Environmental Impact

Bamboo textiles and bamboo composites offer distinct sustainability advantages, with bamboo textiles utilizing renewable fibers that require minimal water and pesticides, significantly reducing ecological footprint compared to conventional fabrics. Bamboo composites incorporate bamboo fibers combined with resins, which may involve synthetic components impacting biodegradability and recycling potential, though they provide durable and lightweight alternatives for construction and automotive industries. The overall environmental impact favors bamboo textiles for renewable sourcing and biodegradability, while bamboo composites balance sustainability with enhanced material performance in specialized applications.

Material Performance: Strength, Durability, and Flexibility

Bamboo composites exhibit superior strength and durability compared to traditional bamboo textiles, making them ideal for high-performance applications such as construction and automotive parts. While bamboo textiles offer excellent flexibility and moisture-wicking properties, they generally lack the structural integrity necessary for load-bearing uses. The material performance of bamboo composites is enhanced by resin impregnation and layering techniques, resulting in a lightweight yet robust composite with enhanced tensile strength and impact resistance.

Common Applications: From Apparel to Construction

Bamboo textiles are widely used in apparel, home textiles, and accessories due to their softness, breathability, and antibacterial properties, making them ideal for eco-friendly clothing and bedding. Bamboo composites, on the other hand, find applications in construction, furniture, and automotive industries because of their high strength-to-weight ratio, durability, and sustainability. Both materials leverage bamboo's rapid growth and renewability, offering versatile solutions across apparel manufacturing and structural engineering.

Cost Analysis: Production and Market Pricing

Bamboo textiles generally feature lower initial production costs due to simpler processing methods like mechanical or chemical treatments, enabling competitive pricing in the apparel and home goods markets. Bamboo composites, involving advanced manufacturing techniques such as resin infusion and layering, incur higher production expenses driving up market prices primarily in automotive and construction industries. Economies of scale in textile production substantially reduce per-unit costs, whereas composite manufacturing still faces challenges in cost efficiency, limiting broader market penetration.

Health and Safety: Benefits and Concerns

Bamboo textiles offer hypoallergenic and breathable properties, reducing skin irritation and promoting comfort, which benefits sensitive individuals. Bamboo composites provide durable and eco-friendly alternatives for construction and automotive industries but may pose inhalation risks from dust or chemical treatments during manufacturing. Proper handling protocols and protective equipment are essential to mitigate potential health concerns in both bamboo textile and composite production.

Future Trends in Bamboo Textiles and Composites

Future trends in bamboo textiles emphasize sustainable fiber innovation, enhancing softness, durability, and moisture-wicking properties for eco-friendly fashion and technical fabrics. Bamboo composites are evolving with improved resin integration and nanocellulose reinforcement, targeting automotive, aerospace, and construction industries for lightweight, high-strength, and biodegradable material solutions. Integration of bio-based additives and circular economy principles drives the convergence of bamboo textiles and composites toward multifunctional, high-performance applications.

bamboo textiles vs bamboo composites Infographic

materialdif.com

materialdif.com