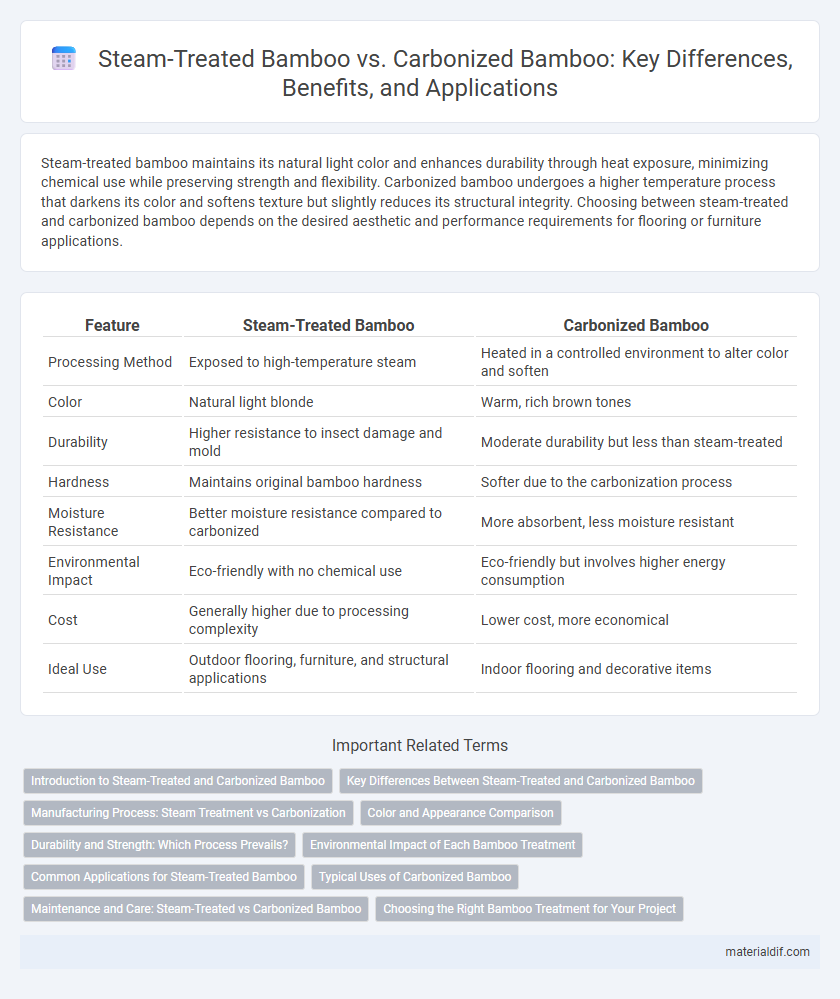

Steam-treated bamboo maintains its natural light color and enhances durability through heat exposure, minimizing chemical use while preserving strength and flexibility. Carbonized bamboo undergoes a higher temperature process that darkens its color and softens texture but slightly reduces its structural integrity. Choosing between steam-treated and carbonized bamboo depends on the desired aesthetic and performance requirements for flooring or furniture applications.

Table of Comparison

| Feature | Steam-Treated Bamboo | Carbonized Bamboo |

|---|---|---|

| Processing Method | Exposed to high-temperature steam | Heated in a controlled environment to alter color and soften |

| Color | Natural light blonde | Warm, rich brown tones |

| Durability | Higher resistance to insect damage and mold | Moderate durability but less than steam-treated |

| Hardness | Maintains original bamboo hardness | Softer due to the carbonization process |

| Moisture Resistance | Better moisture resistance compared to carbonized | More absorbent, less moisture resistant |

| Environmental Impact | Eco-friendly with no chemical use | Eco-friendly but involves higher energy consumption |

| Cost | Generally higher due to processing complexity | Lower cost, more economical |

| Ideal Use | Outdoor flooring, furniture, and structural applications | Indoor flooring and decorative items |

Introduction to Steam-Treated and Carbonized Bamboo

Steam-treated bamboo undergoes a high-temperature, high-pressure steam process that preserves its natural color while enhancing durability and resistance to pests and moisture. Carbonized bamboo is subjected to controlled heat treatment that darkens its color through caramelization, creating a warmer tone but slightly reducing hardness and strength compared to untreated bamboo. Both steam-treated and carbonized bamboo offer sustainable, eco-friendly options for flooring and furniture, with the choice depending on the desired aesthetic and performance characteristics.

Key Differences Between Steam-Treated and Carbonized Bamboo

Steam-treated bamboo retains its natural color and hardness due to exposure to high-pressure steam, preserving its durability and resistance to pests. Carbonized bamboo undergoes heat treatment at high temperatures, resulting in a darker color and softer texture but reduced hardness compared to steam-treated bamboo. The choice between steam-treated and carbonized bamboo affects flooring performance, with steam-treated offering superior strength and carbonized providing enhanced aesthetics.

Manufacturing Process: Steam Treatment vs Carbonization

Steam-treated bamboo undergoes a process where bamboo is exposed to high-pressure steam to remove sugars and increase durability without altering its natural color significantly. Carbonized bamboo is subjected to controlled heating at high temperatures, resulting in a darker color due to caramelization but lower durability compared to steam-treated bamboo. The manufacturing process differences impact the bamboo's strength, color stability, and resistance to pests and moisture.

Color and Appearance Comparison

Steam-treated bamboo exhibits a natural, light golden hue with subtle variations that enhance its organic texture, maintaining a fresh, vibrant appearance. Carbonized bamboo undergoes a heat treatment process that darkens the material to rich amber or caramel tones, creating a uniform, smoother surface with reduced color variation. The choice between steam-treated and carbonized bamboo largely depends on aesthetic preferences for either a brighter, natural look or a deeper, warmer finish.

Durability and Strength: Which Process Prevails?

Steam-treated bamboo retains higher tensile strength and superior durability compared to carbonized bamboo, as the steaming process preserves the bamboo's natural fibers without weakening its structure. Carbonized bamboo undergoes heat treatment that darkens the material but reduces hardness and mechanical strength, making it less resistant to wear and impact. For applications requiring maximum durability and strength, steam-treated bamboo is the preferable choice.

Environmental Impact of Each Bamboo Treatment

Steam-treated bamboo undergoes a high-temperature steaming process that preserves the bamboo's natural color while minimizing chemical use, resulting in a lower environmental footprint with reduced emissions and less toxic runoff compared to other treatments. Carbonized bamboo is exposed to controlled heat in an oxygen-limited environment to darken its color, but this process releases some volatile organic compounds (VOCs) and may weaken the bamboo fibers, potentially decreasing material longevity and increasing environmental costs through more frequent replacement. Choosing steam-treated bamboo supports sustainability efforts due to its eco-friendly processing and better long-term durability, while carbonized bamboo's environmental impact depends on the balance between production emissions and product lifespan.

Common Applications for Steam-Treated Bamboo

Steam-treated bamboo is extensively used in flooring, furniture, and construction due to its enhanced durability and vibrant natural color. This process preserves the bamboo's tensile strength while improving resistance to pests and moisture, making it ideal for indoor and outdoor applications. Common applications include decking, paneling, and cabinetry, where stability and aesthetic appeal are crucial.

Typical Uses of Carbonized Bamboo

Carbonized bamboo is commonly used in flooring, furniture, and decorative wall panels due to its warm color and enhanced aesthetic appeal. This treatment process involves heat exposure that darkens the bamboo fibers, making it ideal for interior design applications where a rich, natural look is desired. Its durability and resistance to moisture also make carbonized bamboo suitable for cabinetry and veneer production.

Maintenance and Care: Steam-Treated vs Carbonized Bamboo

Steam-treated bamboo maintains its natural color and requires minimal maintenance, typically needing only regular cleaning with a damp cloth to prevent dirt buildup and moisture damage. Carbonized bamboo undergoes heat treatment that darkens its color but makes it slightly softer, requiring more careful maintenance to avoid scratches and moisture exposure which can lead to warping or fading over time. Both types benefit from periodic application of appropriate bamboo oils or sealants to extend durability and preserve their aesthetic appeal.

Choosing the Right Bamboo Treatment for Your Project

Steam-treated bamboo retains more of its natural strength and flexibility, making it ideal for structural applications and furniture that require durability. Carbonized bamboo undergoes a heat treatment process that darkens the material and enhances its aesthetics but slightly reduces hardness and resilience. Selecting the right bamboo treatment depends on balancing the need for strength, appearance, and project-specific environmental exposure.

steam-treated bamboo vs carbonized bamboo Infographic

materialdif.com

materialdif.com