Bamboo lyocell and Tencel are both sustainable fibers derived from wood pulp, but bamboo lyocell specifically comes from bamboo plants, offering enhanced breathability and natural antibacterial properties. Tencel, a brand name for lyocell, is produced using a closed-loop process that minimizes environmental impact, delivering a soft, durable fabric with excellent moisture-wicking abilities. Choosing between bamboo lyocell and Tencel depends on desired texture and eco-certifications, as both contribute to eco-friendly fashion with biodegradable and renewable attributes.

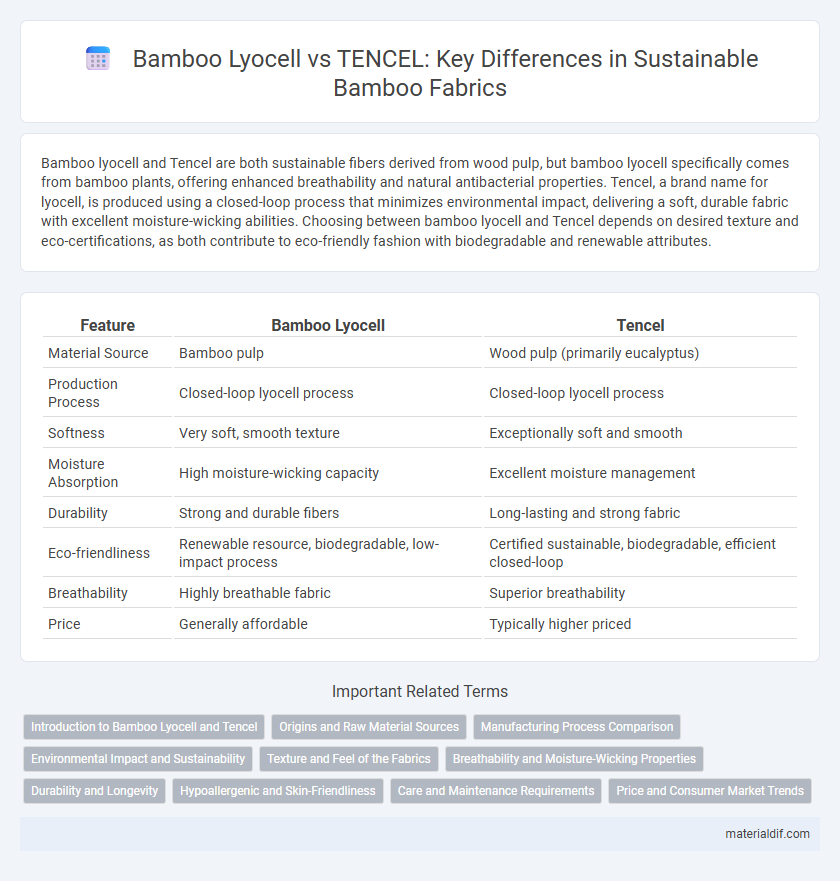

Table of Comparison

| Feature | Bamboo Lyocell | Tencel |

|---|---|---|

| Material Source | Bamboo pulp | Wood pulp (primarily eucalyptus) |

| Production Process | Closed-loop lyocell process | Closed-loop lyocell process |

| Softness | Very soft, smooth texture | Exceptionally soft and smooth |

| Moisture Absorption | High moisture-wicking capacity | Excellent moisture management |

| Durability | Strong and durable fibers | Long-lasting and strong fabric |

| Eco-friendliness | Renewable resource, biodegradable, low-impact process | Certified sustainable, biodegradable, efficient closed-loop |

| Breathability | Highly breathable fabric | Superior breathability |

| Price | Generally affordable | Typically higher priced |

Introduction to Bamboo Lyocell and Tencel

Bamboo lyocell and Tencel are both sustainable fibers derived from natural cellulose sources, with bamboo lyocell specifically produced from bamboo pulp using a closed-loop solvent spinning process that minimizes environmental impact. Tencel, a branded form of lyocell by Lenzing AG, is primarily made from sustainably sourced eucalyptus wood, cotton, and other fast-growing trees, known for its exceptional softness, breathability, and biodegradability. Both fibers offer eco-friendly textile options, with bamboo lyocell highlighting bamboo's rapid renewability and Tencel emphasizing advanced fiber technology and sustainability certifications.

Origins and Raw Material Sources

Bamboo lyocell is derived from bamboo pulp, sourced mainly from fast-growing bamboo species cultivated in Asia, offering a sustainable and renewable raw material base. Tencel, a brand name for lyocell fibers, predominantly originates from sustainably managed eucalyptus, beech, and spruce wood plantations in Europe, emphasizing eco-friendly forestry practices. Both fibers undergo a similar closed-loop production process, but their raw material sources differ in plant species and regional cultivation.

Manufacturing Process Comparison

Bamboo lyocell and Tencel both utilize solvent spinning techniques, yet bamboo lyocell derives cellulose from bamboo pulp while Tencel primarily uses eucalyptus wood. The lyocell process involves a closed-loop solvent system that dissolves cellulose with non-toxic amine oxide, enabling environmentally responsible fiber production. Bamboo lyocell typically demands additional steps to extract cellulose from bamboo's complex structure, making its manufacturing slightly more resource-intensive compared to the streamlined Tencel process.

Environmental Impact and Sustainability

Bamboo lyocell and Tencel are both eco-friendly fibers derived from sustainable cellulose sources, but bamboo lyocell often has a lower environmental impact due to its rapid growth rate and minimal need for pesticides or fertilizers. Tencel, produced by Lenzing, uses a closed-loop process that recycles water and solvents, significantly reducing pollution and energy consumption. Both materials contribute to sustainable textile production, yet bamboo lyocell offers the advantage of faster renewability and biodegradability, making it a strong choice for environmentally conscious consumers.

Texture and Feel of the Fabrics

Bamboo lyocell and Tencel fabrics both offer exceptionally soft textures, but bamboo lyocell tends to feel silkier and smoother due to its naturally round fibers that enhance softness and breathability. Tencel, produced from eucalyptus trees, features a slightly more structured, crisp feel that provides durability while maintaining a gentle touch against the skin. Both fabrics excel in moisture-wicking and temperature regulation, making them comfortable choices for sensitive skin and active wear.

Breathability and Moisture-Wicking Properties

Bamboo lyocell offers superior breathability compared to Tencel, allowing air to circulate freely and keeping the skin cool and dry. Both fibers excel in moisture-wicking, but bamboo lyocell's natural micro-gaps enable faster absorption and evaporation of sweat, enhancing comfort during physical activities. The antimicrobial properties of bamboo lyocell further reduce odor, making it an ideal choice for activewear and bedding.

Durability and Longevity

Bamboo lyocell and Tencel both offer high durability, with bamboo lyocell fibers known for their strong tensile strength and resistance to wear, making garments long-lasting. Tencel, a branded form of lyocell derived from eucalyptus, also provides excellent durability but shines in its consistent fiber quality and resistance to pilling over time. In terms of longevity, both materials maintain their integrity after repeated washes, though bamboo lyocell's denser fiber structure often results in a slightly longer lifespan for textiles in heavy-use applications.

Hypoallergenic and Skin-Friendliness

Bamboo lyocell and Tencel both derive from sustainable wood pulp but differ in fiber processing, impacting hypoallergenic properties. Bamboo lyocell offers excellent moisture-wicking and antimicrobial benefits, making it highly suitable for sensitive skin and reducing allergy risks. Tencel, produced via a closed-loop process from eucalyptus, is known for its softness and breathability, providing comparable skin-friendly qualities with certified eco-friendly credentials.

Care and Maintenance Requirements

Bamboo lyocell and Tencel, both made from cellulose fibers, require gentle care to maintain their softness and durability, with machine washing in cold water and air drying recommended to avoid shrinking or fiber damage. Bamboo lyocell tends to be more moisture-wicking and antibacterial, demanding careful handling to preserve these properties, whereas Tencel benefits from its enhanced wrinkle resistance and color retention, allowing for slightly easier maintenance. Avoiding high heat in laundering and ironing processes helps extend the lifespan of both fibers, ensuring sustainable fabric performance.

Price and Consumer Market Trends

Bamboo lyocell generally offers a more affordable price point compared to Tencel, making it attractive for budget-conscious consumers seeking sustainable fabric options. Consumer market trends show increasing demand for bamboo lyocell due to its eco-friendly production process and natural antibacterial properties, positioning it as a strong competitor against Tencel in the sustainable textile industry. Tencel remains favored for its luxurious feel and brand recognition, yet bamboo lyocell's cost-effectiveness is driving wider adoption in mass-market apparel.

Bamboo lyocell vs Tencel Infographic

materialdif.com

materialdif.com