Bamboo lumber offers a sustainable alternative to engineered wood, boasting rapid growth and high tensile strength that rivals traditional hardwoods. While engineered wood combines wood fibers and adhesives to create versatile panels, bamboo lumber maintains the natural grain and durability of the plant, making it ideal for flooring and furniture. Its eco-friendly production and resilience provide a renewable option for builders seeking both performance and environmental benefits.

Table of Comparison

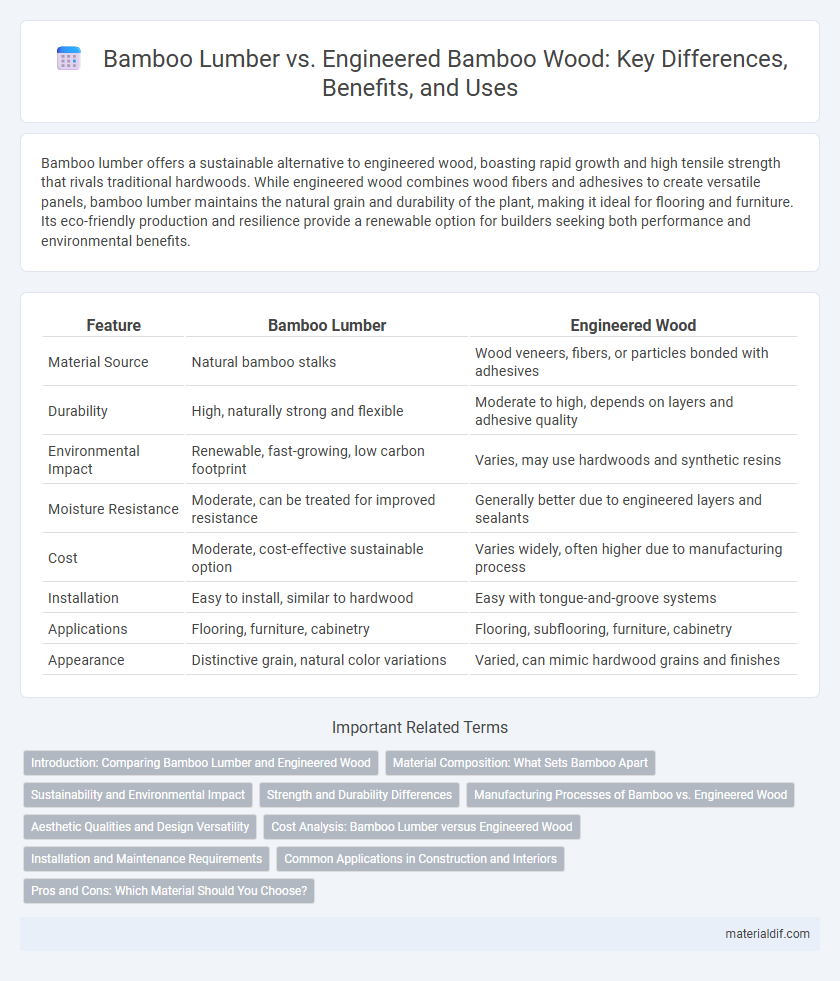

| Feature | Bamboo Lumber | Engineered Wood |

|---|---|---|

| Material Source | Natural bamboo stalks | Wood veneers, fibers, or particles bonded with adhesives |

| Durability | High, naturally strong and flexible | Moderate to high, depends on layers and adhesive quality |

| Environmental Impact | Renewable, fast-growing, low carbon footprint | Varies, may use hardwoods and synthetic resins |

| Moisture Resistance | Moderate, can be treated for improved resistance | Generally better due to engineered layers and sealants |

| Cost | Moderate, cost-effective sustainable option | Varies widely, often higher due to manufacturing process |

| Installation | Easy to install, similar to hardwood | Easy with tongue-and-groove systems |

| Applications | Flooring, furniture, cabinetry | Flooring, subflooring, furniture, cabinetry |

| Appearance | Distinctive grain, natural color variations | Varied, can mimic hardwood grains and finishes |

Introduction: Comparing Bamboo Lumber and Engineered Wood

Bamboo lumber offers a sustainable alternative to traditional engineered wood, characterized by its rapid renewability and high tensile strength. Engineered wood, made from layered wood veneers or fibers bonded with adhesives, provides consistent stability and resistance to warping. This comparison highlights bamboo's eco-friendly growth cycle against engineered wood's structural reliability in modern construction.

Material Composition: What Sets Bamboo Apart

Bamboo lumber is composed of natural bamboo fibers compressed into solid planks, offering superior tensile strength and rapid renewability compared to engineered wood, which is made from wood veneers or fibers bonded with adhesives. The unique cellular structure of bamboo provides enhanced flexibility and resistance to warping, distinguishing it from the layered construction of engineered wood products like plywood or MDF. This natural, fast-growing grass-based composition makes bamboo a sustainable alternative with distinct mechanical properties unmatched by conventional engineered wood materials.

Sustainability and Environmental Impact

Bamboo lumber is a highly sustainable material due to its rapid growth rate, reaching maturity in three to five years, which significantly reduces deforestation pressure compared to traditional hardwoods used in engineered wood. Engineered wood often relies on adhesives and resins containing volatile organic compounds (VOCs), whereas bamboo products tend to have lower emissions, enhancing indoor air quality and reducing environmental pollution. The carbon sequestration capacity of bamboo plantations further contributes to mitigating climate change, positioning bamboo as a superior eco-friendly choice over conventional engineered wood alternatives.

Strength and Durability Differences

Bamboo lumber exhibits exceptional tensile strength, often surpassing traditional hardwoods, making it highly durable for structural applications. Engineered wood combines wood fibers and adhesives to enhance stability and resistance to warping but may not achieve the same natural resilience as bamboo. The inherent density and rapid growth of bamboo contribute to its superior durability, especially in moist and heavy-load environments.

Manufacturing Processes of Bamboo vs. Engineered Wood

Bamboo lumber is manufactured by slicing or shredding raw bamboo stalks into strips, which are then laminated with adhesive under heat and pressure to form solid panels, emphasizing natural fiber alignment for strength. Engineered wood involves combining wood veneers, strands, or fibers with synthetic resins through processes like hot pressing to produce products such as plywood, oriented strand board (OSB), or medium-density fiberboard (MDF). Manufacturing bamboo lumber typically uses a rapid renewable resource with low formaldehyde emissions, while engineered wood relies on timber sourcing and resin chemistry, resulting in different environmental and structural characteristics.

Aesthetic Qualities and Design Versatility

Bamboo lumber offers a natural, warm aesthetic with distinct grain patterns that enhance contemporary and rustic designs, making it a favorite in eco-friendly interiors. Engineered wood provides consistent texture and color, allowing for uniformity in large-scale projects and complex architectural details. Both materials support diverse design versatility, but bamboo's unique visual appeal and sustainable origin often elevate interiors seeking organic charm.

Cost Analysis: Bamboo Lumber versus Engineered Wood

Bamboo lumber typically offers a lower initial cost compared to engineered wood due to its rapid growth and sustainable harvesting methods, making it an economically viable option for eco-conscious projects. Engineered wood, while often more expensive upfront, provides greater dimensional stability and resistance to warping, which can reduce long-term maintenance and replacement costs. When evaluating cost-effectiveness, bamboo's affordability combined with its renewable nature contrasts with engineered wood's enhanced durability and consistent performance, influencing overall project budgets differently.

Installation and Maintenance Requirements

Bamboo lumber offers straightforward installation with its natural strength and flexibility, often requiring simple fastening methods suitable for various construction applications. Engineered wood demands precise installation techniques, including moisture control and specialized adhesives, to maintain structural integrity over time. Maintenance for bamboo lumber involves regular sealing to prevent moisture damage, while engineered wood requires routine inspections to address potential warping or delamination.

Common Applications in Construction and Interiors

Bamboo lumber is widely used in flooring, wall paneling, and furniture due to its natural strength, sustainability, and aesthetic appeal. Engineered wood, comprising layers of veneer or fibers bonded with adhesives, is favored for structural applications, cabinetry, and trim because of its dimensional stability and resistance to warping. Both materials serve distinct roles in construction and interiors, with bamboo preferred for eco-friendly design elements and engineered wood chosen for precision and load-bearing capabilities.

Pros and Cons: Which Material Should You Choose?

Bamboo lumber offers superior sustainability due to its rapid growth and high tensile strength, making it ideal for eco-friendly construction and flooring projects. Engineered wood provides enhanced stability and resistance to warping by combining multiple wood layers, which suits high-moisture environments better than bamboo. Choosing between bamboo lumber and engineered wood depends on factors like environmental impact, durability requirements, cost, and aesthetic preferences.

Bamboo lumber vs Engineered wood Infographic

materialdif.com

materialdif.com