Hot press bamboo involves applying high heat and pressure to compress bamboo fibers, resulting in a denser, more durable material ideal for pet products that require strength and longevity. Cold press bamboo, processed at lower temperatures and pressures, retains more natural moisture and softness, making it suitable for pet items that prioritize comfort and flexibility. Choosing between hot press and cold press bamboo depends on the specific needs of pet products, balancing durability with comfort.

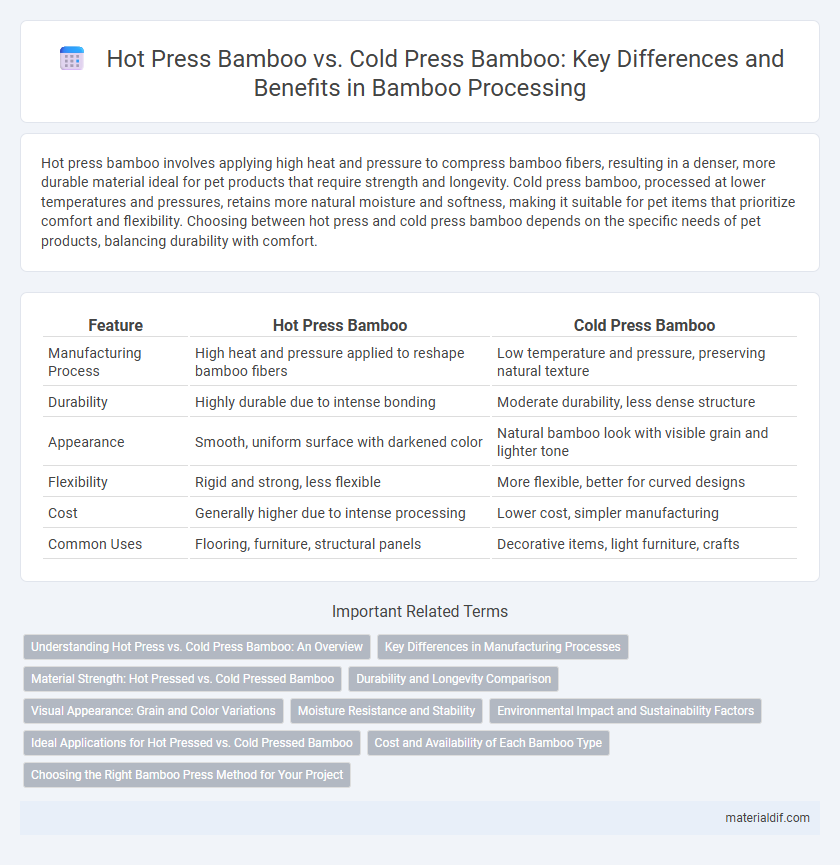

Table of Comparison

| Feature | Hot Press Bamboo | Cold Press Bamboo |

|---|---|---|

| Manufacturing Process | High heat and pressure applied to reshape bamboo fibers | Low temperature and pressure, preserving natural texture |

| Durability | Highly durable due to intense bonding | Moderate durability, less dense structure |

| Appearance | Smooth, uniform surface with darkened color | Natural bamboo look with visible grain and lighter tone |

| Flexibility | Rigid and strong, less flexible | More flexible, better for curved designs |

| Cost | Generally higher due to intense processing | Lower cost, simpler manufacturing |

| Common Uses | Flooring, furniture, structural panels | Decorative items, light furniture, crafts |

Understanding Hot Press vs. Cold Press Bamboo: An Overview

Hot press bamboo undergoes a high-temperature, high-pressure process that enhances durability, density, and moisture resistance, making it ideal for flooring and structural applications. Cold press bamboo involves a lower temperature and pressure technique, preserving more natural fibers and maintaining flexibility, which suits furniture and decorative uses. Understanding these methods helps in selecting bamboo products tailored to specific performance and aesthetic requirements.

Key Differences in Manufacturing Processes

Hot press bamboo undergoes a manufacturing process where high temperature and pressure are applied to compress bamboo fibers, resulting in a denser, more durable material. Cold press bamboo is produced at lower temperatures and pressure, retaining more natural characteristics but typically featuring less strength compared to hot press variants. The choice between hot press and cold press bamboo impacts the material's structural integrity, moisture resistance, and finish quality.

Material Strength: Hot Pressed vs. Cold Pressed Bamboo

Hot pressed bamboo exhibits higher material strength due to its exposure to elevated temperatures and pressure, which enhances fiber bonding and reduces moisture content. Cold pressed bamboo retains more natural flexibility but has comparatively lower density and tensile strength. The manufacturing process of hot pressing results in a denser, more durable bamboo product ideal for structural applications.

Durability and Longevity Comparison

Hot press bamboo undergoes high heat and pressure, resulting in a denser and more durable material with enhanced resistance to moisture, wear, and impact. Cold press bamboo retains more natural fibers, offering moderate durability but lower resilience against environmental stressors compared to hot press variants. For applications requiring longevity and structural integrity, hot press bamboo provides superior performance and extended lifespan.

Visual Appearance: Grain and Color Variations

Hot press bamboo features a smoother, more uniform grain with consistent color tones due to high heat and pressure during manufacturing. Cold press bamboo displays more natural variations in grain pattern and color, offering a rustic and textured appearance. The choice between hot and cold press bamboo affects the visual appeal, with hot press bamboo better suited for sleek, modern aesthetics and cold press bamboo ideal for organic, natural designs.

Moisture Resistance and Stability

Hot press bamboo exhibits superior moisture resistance and enhanced dimensional stability due to the high heat and pressure applied during manufacturing, which densifies the fibers and reduces moisture absorption. Cold press bamboo, processed at lower temperatures, retains higher moisture content, making it more susceptible to swelling and warping in humid environments. The thermal treatment in hot pressing also improves the bamboo's durability and resistance to fungal decay compared to the less stable cold press alternative.

Environmental Impact and Sustainability Factors

Hot press bamboo manufacturing consumes more energy due to high temperatures, increasing its carbon footprint compared to cold press methods. Cold press bamboo production uses less energy and fewer chemicals, resulting in reduced environmental pollution and enhanced sustainability. Choosing cold press bamboo supports eco-friendly practices by minimizing resource use and promoting renewable material benefits.

Ideal Applications for Hot Pressed vs. Cold Pressed Bamboo

Hot press bamboo is ideal for applications requiring enhanced durability and a smoother finish, such as flooring, furniture, and cabinetry due to its dense, compressed structure. Cold press bamboo is better suited for decorative panels, wall coverings, and crafts where natural texture and aesthetic versatility are prioritized. Choosing between hot press and cold press bamboo depends on whether the project demands strength and uniformity or natural appearance and flexibility.

Cost and Availability of Each Bamboo Type

Hot press bamboo typically incurs higher production costs due to the intensive heat and pressure processes involved, resulting in a slightly higher market price compared to cold press bamboo. Cold press bamboo is generally more affordable and widely available because it requires less energy and simpler equipment, making it popular for mass production and budget-conscious consumers. Availability for both types depends on regional manufacturing facilities, with cold press bamboo dominating markets where cost efficiency and rapid production are prioritized.

Choosing the Right Bamboo Press Method for Your Project

Hot press bamboo offers a denser, more durable material ideal for heavy-duty construction and flooring applications, as the high temperature and pressure improve bonding strength and water resistance. Cold press bamboo maintains more natural texture and color variations, making it suitable for decorative projects or artistic uses where aesthetic appeal is prioritized over mechanical strength. Selecting between hot press and cold press methods hinges on project requirements such as load-bearing capacity, surface finish, and environmental exposure.

Hot press bamboo vs Cold press bamboo Infographic

materialdif.com

materialdif.com