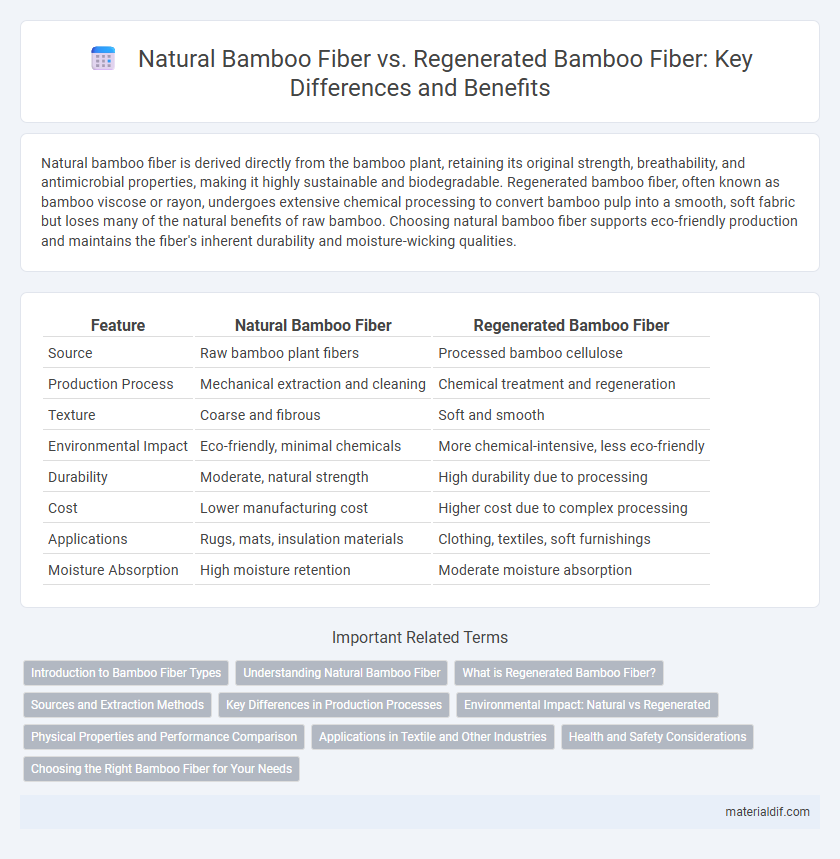

Natural bamboo fiber is derived directly from the bamboo plant, retaining its original strength, breathability, and antimicrobial properties, making it highly sustainable and biodegradable. Regenerated bamboo fiber, often known as bamboo viscose or rayon, undergoes extensive chemical processing to convert bamboo pulp into a smooth, soft fabric but loses many of the natural benefits of raw bamboo. Choosing natural bamboo fiber supports eco-friendly production and maintains the fiber's inherent durability and moisture-wicking qualities.

Table of Comparison

| Feature | Natural Bamboo Fiber | Regenerated Bamboo Fiber |

|---|---|---|

| Source | Raw bamboo plant fibers | Processed bamboo cellulose |

| Production Process | Mechanical extraction and cleaning | Chemical treatment and regeneration |

| Texture | Coarse and fibrous | Soft and smooth |

| Environmental Impact | Eco-friendly, minimal chemicals | More chemical-intensive, less eco-friendly |

| Durability | Moderate, natural strength | High durability due to processing |

| Cost | Lower manufacturing cost | Higher cost due to complex processing |

| Applications | Rugs, mats, insulation materials | Clothing, textiles, soft furnishings |

| Moisture Absorption | High moisture retention | Moderate moisture absorption |

Introduction to Bamboo Fiber Types

Natural bamboo fiber is derived directly from the bamboo plant through mechanical processing, retaining its organic structure and eco-friendly properties, often used in sustainable textiles. Regenerated bamboo fiber, also known as bamboo viscose or rayon, involves chemically dissolving bamboo cellulose and reforming it into fibers, offering softness and durability but with higher environmental impact. Understanding these two bamboo fiber types is essential for evaluating their applications in eco-conscious fashion and textile industries.

Understanding Natural Bamboo Fiber

Natural bamboo fiber is derived directly from the bamboo plant through mechanical processing that retains its cellulose structure, resulting in a breathable and eco-friendly fabric. It offers superior moisture-wicking and antibacterial properties due to the presence of natural bamboo components like bamboo kun. Unlike regenerated bamboo fiber, which undergoes chemical treatments to produce viscose or rayon, natural bamboo fiber maintains its sustainable and biodegradable qualities without synthetic additives.

What is Regenerated Bamboo Fiber?

Regenerated bamboo fiber is a type of man-made fiber produced by chemically processing bamboo pulp into viscose or rayon, resulting in a soft, smooth textile that retains bamboo's natural strength and antibacterial properties. Unlike natural bamboo fiber, which is made by mechanically crushing bamboo stalks, regenerated bamboo fibers undergo a transformation that enhances fabric durability and drape. This process makes regenerated bamboo fiber a popular choice for eco-friendly clothing and home textiles due to its sustainability and comfort.

Sources and Extraction Methods

Natural bamboo fiber is derived directly from the bamboo plant through mechanical crushing and degumming processes that separate fibers from the woody material, resulting in a more eco-friendly and less chemically intensive product. Regenerated bamboo fiber, also known as bamboo viscose, is produced by chemically dissolving bamboo cellulose using solvents such as sodium hydroxide and carbon disulfide, followed by spinning the solution into fiber, which involves more complex and potentially pollutive extraction methods. The choice between natural and regenerated bamboo fiber impacts sustainability, with natural fibers maintaining the structural integrity of bamboo and regenerated fibers offering increased softness but relying on chemical processing.

Key Differences in Production Processes

Natural bamboo fiber is extracted directly from bamboo stalks using mechanical processes like crushing and retting, preserving the fiber's natural cellulose structure and resulting in a more eco-friendly material. Regenerated bamboo fiber, often called bamboo viscose or rayon, is produced through chemical processes that dissolve bamboo pulp with strong solvents to regenerate fibers, leading to higher uniformity but increased environmental impact. The key difference lies in the mechanical versus chemical extraction methods, affecting sustainability, fiber texture, and production complexity.

Environmental Impact: Natural vs Regenerated

Natural bamboo fiber is harvested directly from the bamboo plant, involving minimal processing and lower chemical usage, resulting in a smaller environmental footprint compared to regenerated bamboo fiber. Regenerated bamboo fiber undergoes intensive chemical treatments, including toxic solvents like carbon disulfide, which contribute to pollution and energy consumption during production. Sustainable bamboo textile manufacturing favors natural bamboo fiber for its biodegradability and reduced ecological impact, aligning with eco-friendly material goals.

Physical Properties and Performance Comparison

Natural bamboo fiber exhibits exceptional strength, breathability, and moisture-wicking properties, making it highly durable and comfortable for textiles. Regenerated bamboo fiber, chemically processed from bamboo pulp, offers a smoother texture and consistent quality but may have reduced tensile strength and breathability compared to natural fibers. Performance-wise, natural bamboo fiber excels in biodegradability and antibacterial properties, whereas regenerated fibers provide enhanced uniformity and versatility in fabric production.

Applications in Textile and Other Industries

Natural bamboo fiber, derived directly from bamboo pulp through mechanical processes, offers high strength, breathability, and antibacterial properties ideal for sustainable textiles and home furnishings. Regenerated bamboo fiber, produced chemically by dissolving bamboo cellulose and reforming it into viscose or rayon, combines softness and moisture-wicking characteristics, widely used in fashion apparel, bedding, and medical textiles. Both fibers find extended applications in automotive interiors, eco-friendly composites, and biodegradable packaging, leveraging bamboo's rapid renewability and biodegradability for innovative industrial uses.

Health and Safety Considerations

Natural bamboo fiber retains inherent antibacterial properties and breathability, making it a healthier choice for sensitive skin and reducing risks of irritation or allergies. Regenerated bamboo fiber undergoes chemical processing, which may introduce harmful residues or weaken biodegradability, raising concerns about skin sensitivity and environmental safety. Opting for natural bamboo fiber ensures fewer chemical exposures and aligns better with sustainable health practices.

Choosing the Right Bamboo Fiber for Your Needs

Natural bamboo fiber, derived directly from bamboo plants through mechanical processing, retains the plant's original strength, breathability, and antibacterial properties, making it ideal for eco-conscious consumers seeking sustainability and durability. Regenerated bamboo fiber, produced by chemically processing bamboo cellulose into viscose or rayon, offers a softer, silk-like texture suitable for lightweight, smooth-textured fabrics but may involve environmental concerns due to chemical usage. Selecting the right bamboo fiber depends on prioritizing natural environmental impact and fiber strength versus softness and fabric versatility in daily wear or textile applications.

Natural bamboo fiber vs Regenerated bamboo fiber Infographic

materialdif.com

materialdif.com