Bamboo laminate offers a smooth, uniform surface ideal for furniture and flooring, providing enhanced durability and moisture resistance compared to plywood bamboo. Plywood bamboo consists of multiple layers of bamboo veneers glued together, making it stronger but often less consistent in appearance. Choosing between bamboo laminate and plywood bamboo depends on the required strength, aesthetic preference, and application environment.

Table of Comparison

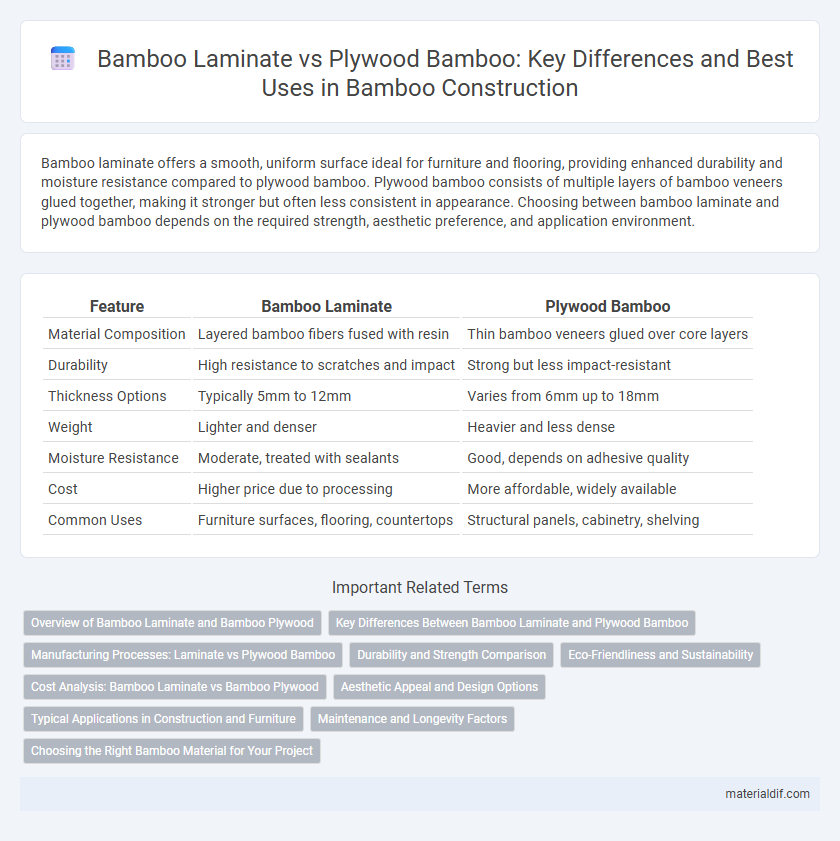

| Feature | Bamboo Laminate | Plywood Bamboo |

|---|---|---|

| Material Composition | Layered bamboo fibers fused with resin | Thin bamboo veneers glued over core layers |

| Durability | High resistance to scratches and impact | Strong but less impact-resistant |

| Thickness Options | Typically 5mm to 12mm | Varies from 6mm up to 18mm |

| Weight | Lighter and denser | Heavier and less dense |

| Moisture Resistance | Moderate, treated with sealants | Good, depends on adhesive quality |

| Cost | Higher price due to processing | More affordable, widely available |

| Common Uses | Furniture surfaces, flooring, countertops | Structural panels, cabinetry, shelving |

Overview of Bamboo Laminate and Bamboo Plywood

Bamboo laminate is manufactured by bonding thin layers of bamboo strips with adhesives under high pressure, resulting in a durable, smooth surface ideal for furniture and flooring applications. Bamboo plywood consists of multiple layers of bamboo veneers glued together, offering enhanced strength and stability while maintaining the natural aesthetic of bamboo. Both materials provide eco-friendly alternatives to traditional wood products, with bamboo laminate emphasizing surface finish and bamboo plywood focusing on structural integrity.

Key Differences Between Bamboo Laminate and Plywood Bamboo

Bamboo laminate is created by pressing thin layers of bamboo veneer with resin adhesives to form a durable surface, offering enhanced resistance to moisture and scratches compared to plywood bamboo, which consists of multiple bamboo strips glued together for structural strength. The density of bamboo laminate typically provides a smoother, more uniform finish ideal for furniture and flooring, while plywood bamboo excels in load-bearing applications due to its layered construction. Bamboo laminate often features a thinner profile and higher aesthetic versatility, whereas plywood bamboo emphasizes robust mechanical properties and easier customization for builders and designers.

Manufacturing Processes: Laminate vs Plywood Bamboo

Bamboo laminate is produced by compressing thin layers of bamboo fibers bonded with adhesives under high pressure and heat, resulting in a dense, smooth, and durable surface ideal for flooring and furniture. In contrast, plywood bamboo is manufactured by layering thin bamboo veneers with alternating grain direction, glued and pressed together to enhance strength and stability while maintaining flexibility. The laminate's manufacturing process delivers a more uniform and aesthetically consistent product, whereas plywood's cross-layered construction provides superior resistance to warping and splitting.

Durability and Strength Comparison

Bamboo laminate offers superior durability with a dense, cross-laminated structure that resists warping and cracking better than plywood bamboo, which tends to have more natural weaknesses due to its layered veneer composition. The tensile strength of bamboo laminate often exceeds that of plywood bamboo, providing enhanced load-bearing capacity and impact resistance. High-quality bamboo laminate panels maintain stability in moisture-prone environments, whereas plywood bamboo may delaminate or swell under similar conditions.

Eco-Friendliness and Sustainability

Bamboo laminate offers superior eco-friendliness compared to plywood bamboo due to its renewable growth cycle, typically reaching maturity within 3-5 years, significantly faster than traditional hardwoods used in plywood. The production of bamboo laminate involves fewer chemicals and lower energy consumption, reducing its overall carbon footprint and environmental impact. In contrast, plywood bamboo often relies on adhesives and resins that may contain formaldehyde, posing sustainability concerns and potential health risks over time.

Cost Analysis: Bamboo Laminate vs Bamboo Plywood

Bamboo laminate generally costs more than bamboo plywood due to its manufacturing process, which involves layering and compressing thin bamboo veneers with adhesive resins for enhanced durability and finish quality. Bamboo plywood, made by gluing multiple bamboo layers together, offers a more affordable option while maintaining strength and flexibility suitable for various construction and furniture applications. Evaluating project requirements and budget constraints is essential to determine whether the higher upfront cost of bamboo laminate is justified by its superior aesthetic appeal and resistance properties compared to bamboo plywood.

Aesthetic Appeal and Design Options

Bamboo laminate offers a sleek, uniform surface with consistent grain patterns, ideal for modern and minimalist design aesthetics, while plywood bamboo provides a more natural and varied texture that enhances rustic and organic interior styles. The laminate's versatile color finishes and smooth texture allow for greater customization, whereas plywood bamboo retains distinctive knots and layers, adding unique character to furniture and flooring. Both materials support sustainable design choices, but bamboo laminate excels in delivering a polished, contemporary look with diverse design options.

Typical Applications in Construction and Furniture

Bamboo laminate offers superior durability and moisture resistance, making it ideal for flooring, cabinetry, and countertops in both residential and commercial construction. Plywood bamboo, composed of layered bamboo veneers, is commonly used in structural framing, wall panels, and furniture components due to its strength and flexibility. Both materials are favored for eco-friendly projects, but bamboo laminate excels in high-traffic surfaces while plywood bamboo is preferred for load-bearing and customizable furniture designs.

Maintenance and Longevity Factors

Bamboo laminate offers a durable, low-maintenance surface resistant to scratches and moisture, making it ideal for high-traffic areas. Plywood bamboo, while strong and eco-friendly, requires regular sealing and protection from prolonged water exposure to prevent warping and degradation. Longevity of bamboo laminates typically exceeds that of plywood bamboo when properly maintained, ensuring sustained aesthetic and structural performance.

Choosing the Right Bamboo Material for Your Project

Bamboo laminate offers superior durability and resistance to moisture compared to plywood bamboo, making it ideal for high-traffic or wet environments. Plywood bamboo, constructed from layered bamboo veneers, provides greater structural strength and flexibility for furniture and cabinetry. Selecting the right bamboo material depends on the specific application, balancing factors like load-bearing needs, exposure to humidity, and aesthetic preferences.

bamboo laminate vs plywood bamboo Infographic

materialdif.com

materialdif.com