Natural bamboo is a sustainable, eco-friendly material known for its strength, flexibility, and rapid growth, making it an ideal choice for environmentally conscious construction and products. Processed bamboo, often transformed into bamboo fiber, plywood, or laminate, undergoes chemical treatments that can reduce its natural durability and increase the carbon footprint associated with manufacturing. Choosing natural bamboo supports biodiversity and soil health, while processed bamboo offers versatility but may compromise some of the ecological benefits inherent in raw bamboo.

Table of Comparison

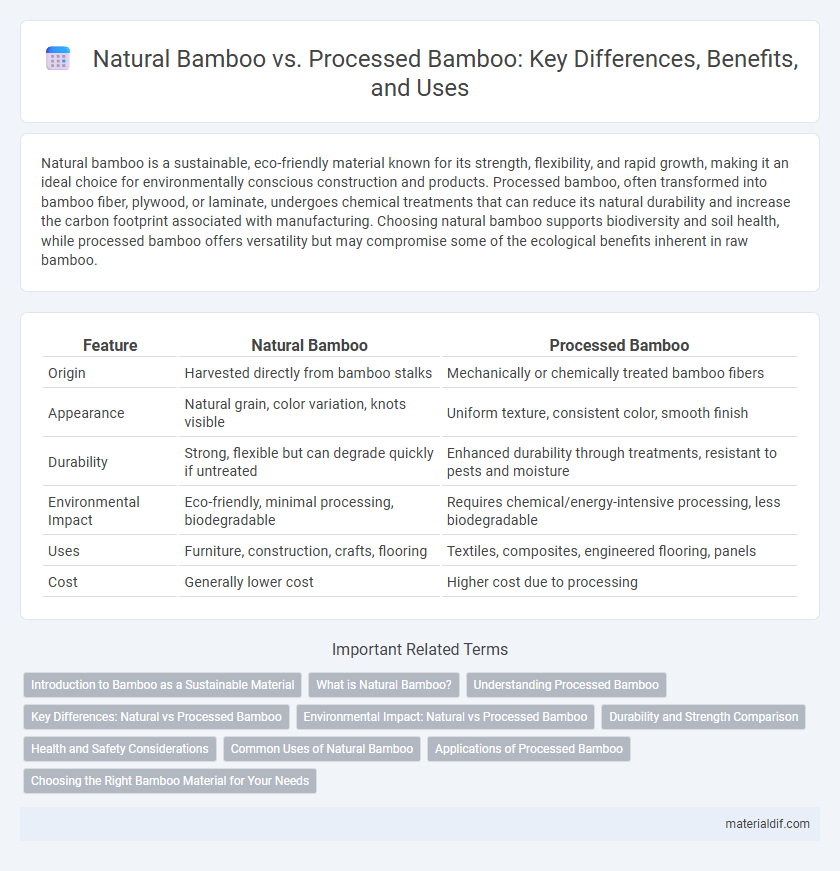

| Feature | Natural Bamboo | Processed Bamboo |

|---|---|---|

| Origin | Harvested directly from bamboo stalks | Mechanically or chemically treated bamboo fibers |

| Appearance | Natural grain, color variation, knots visible | Uniform texture, consistent color, smooth finish |

| Durability | Strong, flexible but can degrade quickly if untreated | Enhanced durability through treatments, resistant to pests and moisture |

| Environmental Impact | Eco-friendly, minimal processing, biodegradable | Requires chemical/energy-intensive processing, less biodegradable |

| Uses | Furniture, construction, crafts, flooring | Textiles, composites, engineered flooring, panels |

| Cost | Generally lower cost | Higher cost due to processing |

Introduction to Bamboo as a Sustainable Material

Natural bamboo is a fast-growing grass known for its strength, flexibility, and biodegradability, making it a highly sustainable material for construction, textiles, and everyday products. Processed bamboo, which undergoes treatments like carbonization, bleaching, or chemical processing, offers enhanced durability and uniformity but may involve environmental trade-offs depending on the methods used. Choosing bamboo in its natural or minimally processed form supports eco-friendly practices due to its carbon sequestration capability and minimal resource requirements compared to traditional hardwoods.

What is Natural Bamboo?

Natural bamboo refers to bamboo in its raw, unprocessed form, harvested directly from bamboo forests or plantations. It retains its original structural properties, including high tensile strength, natural moisture content, and resistance to pests due to its silica content. This raw material is commonly used in construction, furniture making, and eco-friendly products where minimal processing preserves its sustainability and durability.

Understanding Processed Bamboo

Processed bamboo undergoes treatments such as bleaching, dyeing, and smoothing to enhance its durability, texture, and appearance compared to natural bamboo. This transformation increases resistance to pests, moisture, and wear, making processed bamboo ideal for flooring, furniture, and textiles. Understanding the chemical and mechanical modifications involved is essential for evaluating the environmental impact and performance of processed bamboo products.

Key Differences: Natural vs Processed Bamboo

Natural bamboo retains its original fibrous structure, offering high tensile strength, breathability, and natural antibacterial properties. Processed bamboo undergoes chemical or mechanical treatments to extract fibers or transform into products like bamboo fabric, reducing some natural benefits but enhancing softness and flexibility. The key differences lie in texture, environmental impact, durability, and applications, with natural bamboo favored for construction and sustainability, while processed bamboo is preferred in textiles and consumer goods.

Environmental Impact: Natural vs Processed Bamboo

Natural bamboo serves as a highly sustainable resource, boasting rapid growth and carbon sequestration properties that aid in reducing environmental pollution. Processed bamboo undergoes chemical treatments and energy-intensive manufacturing that increase its carbon footprint and release harmful pollutants. Choosing natural bamboo minimizes habitat disruption and waste, supporting eco-friendly practices and biodiversity conservation.

Durability and Strength Comparison

Natural bamboo boasts impressive tensile strength, often surpassing steel in certain applications, making it highly durable in its raw form. Processed bamboo undergoes treatments such as heat pressing and chemical enhancement, which significantly improve its resistance to moisture, pests, and decay, extending its lifespan in construction and furniture. The engineered bamboo products exhibit more uniform strength and greater structural stability compared to untreated bamboo, making them preferable for load-bearing uses.

Health and Safety Considerations

Natural bamboo is a sustainable, chemical-free material known for its antimicrobial properties and hypoallergenic benefits, making it safe for direct contact with skin. Processed bamboo products often involve chemical treatments or adhesives, which can release volatile organic compounds (VOCs) and pose potential health risks, especially in poorly ventilated areas. Choosing natural bamboo ensures minimal exposure to toxins, while verifying certifications for processed bamboo can help mitigate safety concerns related to chemical additives.

Common Uses of Natural Bamboo

Natural bamboo is widely used in construction, furniture-making, and traditional crafts due to its strength, flexibility, and sustainability. Its applications include scaffolding, flooring, baskets, and musical instruments, capitalizing on its natural durability and lightweight properties. Unlike processed bamboo, natural bamboo retains its organic texture, making it ideal for eco-friendly and artisanal products.

Applications of Processed Bamboo

Processed bamboo features enhanced durability, moisture resistance, and uniformity, making it ideal for construction materials, furniture, and flooring. Its treated fibers allow for versatile applications in textiles, biodegradable composites, and eco-friendly packaging solutions. This adaptability positions processed bamboo as a sustainable alternative in industries seeking renewable and high-performance materials.

Choosing the Right Bamboo Material for Your Needs

Natural bamboo offers unmatched sustainability and biodegradability, making it ideal for eco-friendly projects and applications requiring high-strength fibers. Processed bamboo, treated for durability and enhanced aesthetics, suits products demanding uniformity and resistance to moisture or pests, such as flooring and furniture. Selecting the right bamboo material depends on balancing natural authenticity with performance needs specific to your intended use.

Natural bamboo vs Processed bamboo Infographic

materialdif.com

materialdif.com