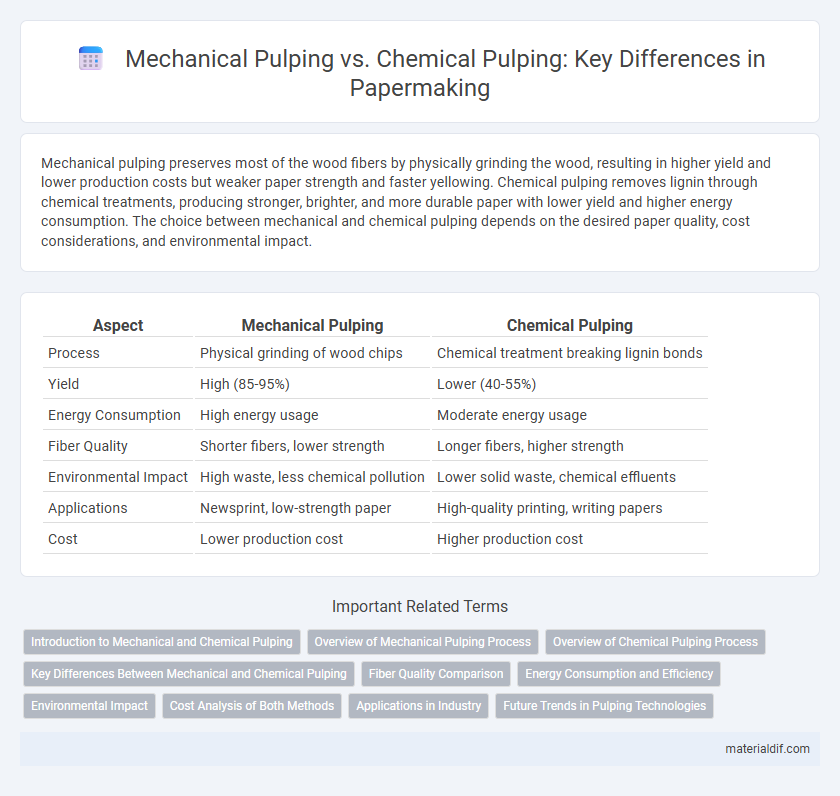

Mechanical pulping preserves most of the wood fibers by physically grinding the wood, resulting in higher yield and lower production costs but weaker paper strength and faster yellowing. Chemical pulping removes lignin through chemical treatments, producing stronger, brighter, and more durable paper with lower yield and higher energy consumption. The choice between mechanical and chemical pulping depends on the desired paper quality, cost considerations, and environmental impact.

Table of Comparison

| Aspect | Mechanical Pulping | Chemical Pulping |

|---|---|---|

| Process | Physical grinding of wood chips | Chemical treatment breaking lignin bonds |

| Yield | High (85-95%) | Lower (40-55%) |

| Energy Consumption | High energy usage | Moderate energy usage |

| Fiber Quality | Shorter fibers, lower strength | Longer fibers, higher strength |

| Environmental Impact | High waste, less chemical pollution | Lower solid waste, chemical effluents |

| Applications | Newsprint, low-strength paper | High-quality printing, writing papers |

| Cost | Lower production cost | Higher production cost |

Introduction to Mechanical and Chemical Pulping

Mechanical pulping involves physically grinding wood chips to separate fibers while preserving most of the lignin, resulting in higher yield but lower paper strength and brightness. Chemical pulping uses chemicals such as sodium hydroxide and sodium sulfide in the Kraft process to dissolve lignin and free cellulose fibers, producing stronger, brighter pulp with lower yield. Both methods serve distinct industrial needs depending on the desired paper quality, production cost, and environmental impact.

Overview of Mechanical Pulping Process

Mechanical pulping involves physically grinding wood chips into pulp using machinery such as refiners or grinders, preserving most of the lignin content. This process yields higher pulp volume and brightness suitable for newsprint and paperboard but results in lower strength and durability compared to chemical pulping. Energy consumption is significantly higher in mechanical pulping, making it less efficient but more cost-effective for specific paper products.

Overview of Chemical Pulping Process

Chemical pulping involves breaking down wood chips into pulp by cooking them in a chemical solution, primarily using the kraft or sulfite processes, which remove lignin to separate fibers. This process produces stronger and higher-quality paper compared to mechanical pulping due to the effective lignin removal and fiber preservation. Key chemicals include sodium hydroxide and sodium sulfide in kraft pulping, contributing to the durability and brightness of the resulting pulp.

Key Differences Between Mechanical and Chemical Pulping

Mechanical pulping uses physical force to separate fibers, preserving most of the wood's components, which results in higher yield but lower paper strength and brightness. Chemical pulping employs chemicals like sodium hydroxide and sodium sulfide to dissolve lignin, producing stronger, brighter paper with lower yield due to fiber loss. Key differences include energy consumption, with mechanical pulping requiring more energy, and environmental impact, as chemical pulping generates more pollutants from chemical recovery processes.

Fiber Quality Comparison

Mechanical pulping preserves more lignin, resulting in fibers that are shorter, bulkier, and less flexible compared to chemical pulping, which removes lignin and produces longer, stronger, and more uniform fibers. Chemical pulping fibers exhibit superior strength, brightness, and durability, making them ideal for high-quality paper products, while mechanical pulp fibers tend to yield paper with higher opacity but lower tensile strength. The fiber quality differences significantly affect the final paper properties, influencing its application in printing, packaging, and specialty papers.

Energy Consumption and Efficiency

Mechanical pulping consumes significantly more energy compared to chemical pulping, often requiring 2-4 times the electricity per ton of pulp produced, due to the intense grinding processes involved. Chemical pulping, though slower, relies on chemicals to break down lignin, resulting in higher pulp yield and better fiber quality with lower overall energy consumption. Efficiency in chemical pulping is enhanced by recovery systems that recycle chemicals and energy, making it a more sustainable choice for large-scale paper production.

Environmental Impact

Mechanical pulping consumes less energy compared to chemical pulping but results in higher water pollution due to the release of organic materials. Chemical pulping, particularly the kraft process, produces strong fibers and less water contamination but generates hazardous chemical waste that requires treatment. Overall, mechanical pulping has a higher environmental footprint in terms of water quality, while chemical pulping poses challenges related to chemical management and emissions.

Cost Analysis of Both Methods

Mechanical pulping incurs higher energy costs due to intensive grinding processes, while chemical pulping demands significant expenses related to chemicals and recovery systems. Despite higher operational energy use, mechanical pulping offers lower raw material costs by utilizing whole wood, contrasting with the chemical method's selective lignin removal, affecting yield and waste management. Cost efficiency varies by scale and end-use, with chemical pulping favored for high-quality paper production but mechanical pulping cost-effective for bulk paper products.

Applications in Industry

Mechanical pulping is primarily employed in the production of newsprint, magazines, and packaging materials due to its high yield and retention of fiber length, which enhances bulk and opacity. Chemical pulping, notably kraft and sulfite processes, dominates in the manufacture of high-quality printing paper, tissue paper, and specialty paper products where strength and purity are critical. The paper industry favors chemical pulping for applications requiring superior durability and brightness, while mechanical pulping is preferred for cost-effective, high-volume outputs.

Future Trends in Pulping Technologies

Future trends in pulping technologies emphasize sustainable innovations, with mechanical pulping advancing through energy-efficient refinements and chemical pulping evolving via greener, less toxic reagents. The integration of enzymatic treatments and biorefinery concepts aims to enhance fiber quality while reducing environmental impact. Emerging hybrid pulping techniques combine mechanical and chemical processes to optimize yield and minimize resource consumption.

Mechanical Pulping vs Chemical Pulping Infographic

materialdif.com

materialdif.com