Cork finish offers a natural, eco-friendly surface that enhances warmth and texture, while polyurethane finish provides a durable, glossy coating resistant to scratches and water damage. Choosing between cork finish and polyurethane depends on prioritizing eco-conscious aesthetics or long-lasting protection. Cork surfaces require more maintenance to preserve their appearance, whereas polyurethane finishes deliver easier cleaning and extended lifespan.

Table of Comparison

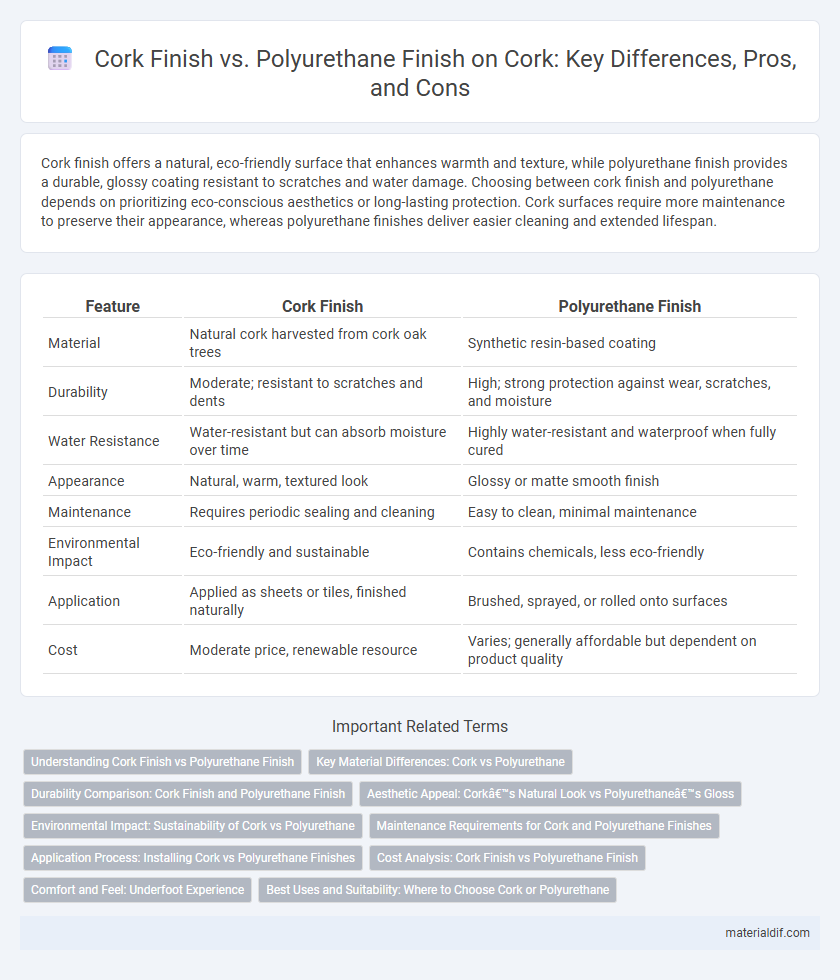

| Feature | Cork Finish | Polyurethane Finish |

|---|---|---|

| Material | Natural cork harvested from cork oak trees | Synthetic resin-based coating |

| Durability | Moderate; resistant to scratches and dents | High; strong protection against wear, scratches, and moisture |

| Water Resistance | Water-resistant but can absorb moisture over time | Highly water-resistant and waterproof when fully cured |

| Appearance | Natural, warm, textured look | Glossy or matte smooth finish |

| Maintenance | Requires periodic sealing and cleaning | Easy to clean, minimal maintenance |

| Environmental Impact | Eco-friendly and sustainable | Contains chemicals, less eco-friendly |

| Application | Applied as sheets or tiles, finished naturally | Brushed, sprayed, or rolled onto surfaces |

| Cost | Moderate price, renewable resource | Varies; generally affordable but dependent on product quality |

Understanding Cork Finish vs Polyurethane Finish

Cork finish enhances natural cork flooring by providing a breathable, flexible coating that maintains its eco-friendly and soft characteristics, while polyurethane finish creates a durable, glossy barrier ideal for high-traffic areas and moisture resistance. Cork finishes emphasize sustainability and natural texture, making them suitable for residential spaces seeking warmth and comfort. Polyurethane finishes offer superior protection against scratches, stains, and wear, making them preferred in commercial settings or places requiring longevity and ease of maintenance.

Key Material Differences: Cork vs Polyurethane

Cork finish offers a natural, renewable material characterized by its soft, porous structure that provides excellent insulation and moisture resistance. Polyurethane finish, a synthetic polymer coating, creates a hard, durable surface that offers superior scratch and chemical resistance. Cork's breathable, eco-friendly properties contrast with polyurethane's robust, protective barrier suitable for high-traffic areas.

Durability Comparison: Cork Finish and Polyurethane Finish

Cork finish offers natural resilience by absorbing impacts and resisting minor scratches, making it highly durable for moderate traffic areas. Polyurethane finish excels in hardness and chemical resistance, providing superior protection against wear, moisture, and stains in high-traffic or industrial environments. Cork finish requires periodic sealing to maintain longevity, whereas polyurethane finish creates a robust, long-lasting barrier that demands less frequent maintenance.

Aesthetic Appeal: Cork’s Natural Look vs Polyurethane’s Gloss

Cork finish enhances interior spaces with its warm, natural texture and matte appearance, offering a soft, organic aesthetic that complements eco-friendly designs. Polyurethane finish provides a glossy, highly reflective surface that accentuates color depth and adds a polished, modern appeal to flooring or furniture. While cork emphasizes a subdued, earthy look, polyurethane finish delivers vibrant shine and durability for a more contemporary visual impact.

Environmental Impact: Sustainability of Cork vs Polyurethane

Cork finish is a highly sustainable choice, derived from the renewable bark of cork oak trees that regenerate without harming the tree, making it an eco-friendly option with a low carbon footprint. In contrast, polyurethane finish is a synthetic product made from petroleum-based chemicals, contributing to environmental pollution and non-biodegradability concerns. The production and disposal of polyurethane generate more harmful emissions compared to the biodegradable, recyclable, and natural properties of cork finish.

Maintenance Requirements for Cork and Polyurethane Finishes

Cork finishes require regular cleaning with mild, pH-balanced cleaners and periodic reapplication of sealants to maintain their natural resilience and prevent moisture damage. Polyurethane finishes offer a more durable, water-resistant surface that demands less frequent maintenance, primarily involving simple cleaning and occasional polishing to preserve their glossy appearance. Both finishes benefit from prompt spill cleanup, but cork's softer surface is more prone to scratches and dents compared to the tougher polyurethane coating.

Application Process: Installing Cork vs Polyurethane Finishes

Installing cork finishes involves laying natural cork tiles or planks that often come pre-finished, requiring minimal on-site treatment and ensuring a quick, clean installation. Polyurethane finishes demand a multi-step application process including surface sanding, multiple coats of liquid polyurethane, and adequate drying time between layers to achieve a durable, glossy surface. Cork installation prioritizes ease and speed with adhesive application to subfloor surfaces, while polyurethane finishes focus on careful manual or sprayed application over wood to enhance protection and aesthetics.

Cost Analysis: Cork Finish vs Polyurethane Finish

Cork finish typically costs more upfront due to the natural material and specialized installation process, ranging from $5 to $10 per square foot, whereas polyurethane finish is generally priced between $3 and $7 per square foot. Maintenance expenses for cork remain lower over time because of its natural resilience and self-healing properties, while polyurethane requires periodic reapplication that adds to long-term costs. Evaluating total cost of ownership reveals cork finish as a durable, eco-friendly option justifying its higher initial investment compared to the more economical polyurethane finish.

Comfort and Feel: Underfoot Experience

Cork finish provides a warm, cushioned underfoot experience due to its natural elasticity and cellular structure, offering superior comfort and sound absorption compared to polyurethane finish. Polyurethane finish, while durable and resistant to scratches, can feel harder and less forgiving underfoot, which may reduce overall comfort during prolonged standing or walking. The natural softness and thermal insulation of cork make it an ideal choice for spaces prioritizing a cozy, comfortable feel.

Best Uses and Suitability: Where to Choose Cork or Polyurethane

Cork finish offers excellent sound insulation and natural cushioning, making it ideal for residential spaces, yoga studios, and eco-friendly commercial areas where comfort and sustainability are priorities. Polyurethane finish provides superior durability and resistance to moisture, making it suitable for high-traffic areas, kitchens, and bathrooms that require long-lasting protection and easy maintenance. Choosing cork is best for areas emphasizing warmth and environmental benefits, while polyurethane is preferred in environments demanding toughness and moisture resistance.

Cork Finish vs Polyurethane Finish Infographic

materialdif.com

materialdif.com